Vibrating disc feeding device and method for pocket long-diameter shell breaking equipment

A technology of feeding device and vibrating plate, which is applied in the direction of shelling, transportation and packaging, and conveyors, can solve the problems of prone to jamming, inconvenient dredging, and long shutdown maintenance time, so as to reduce the loss rate of kernels and improve The effect of improving processing efficiency and improving shell breaking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

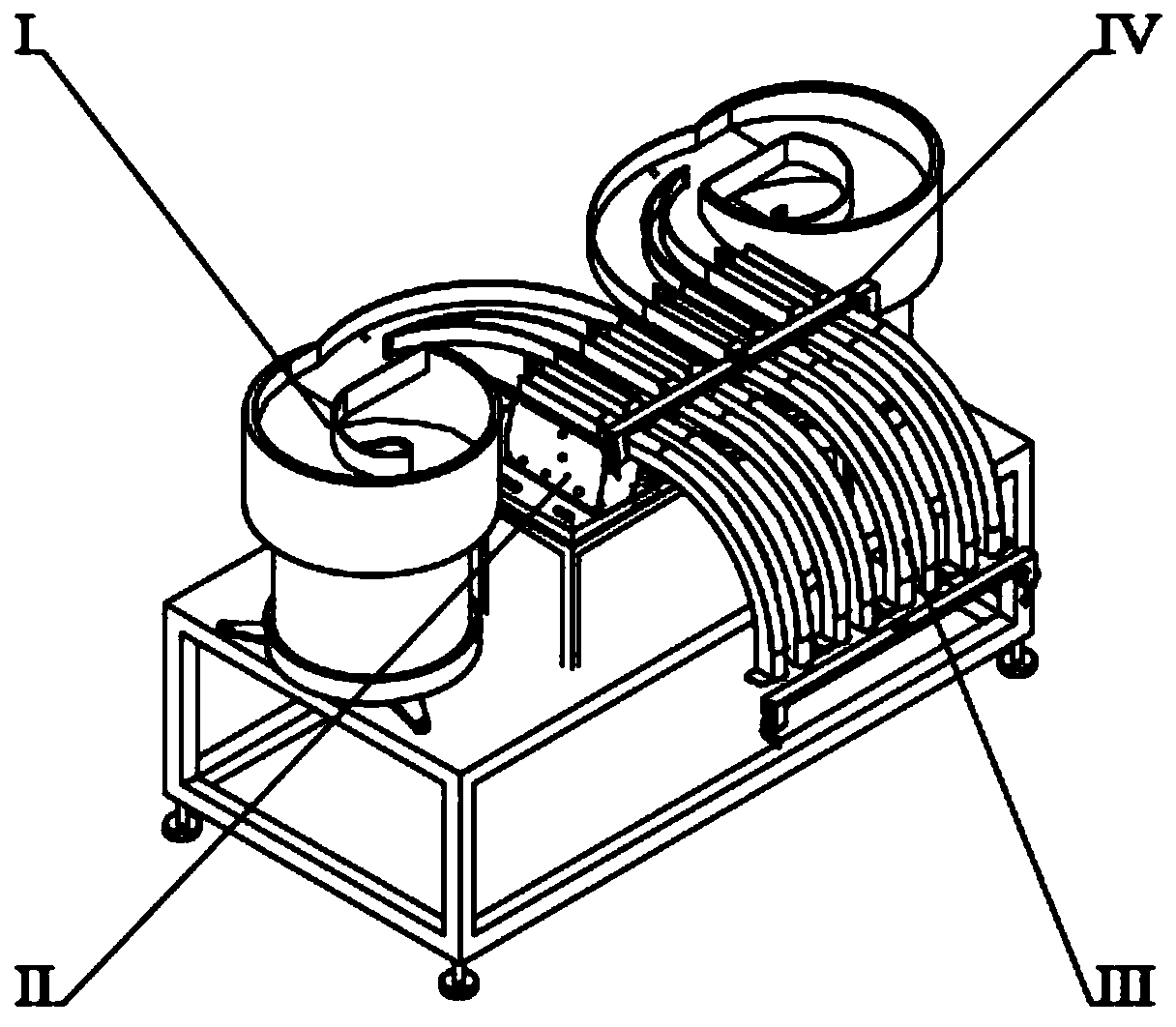

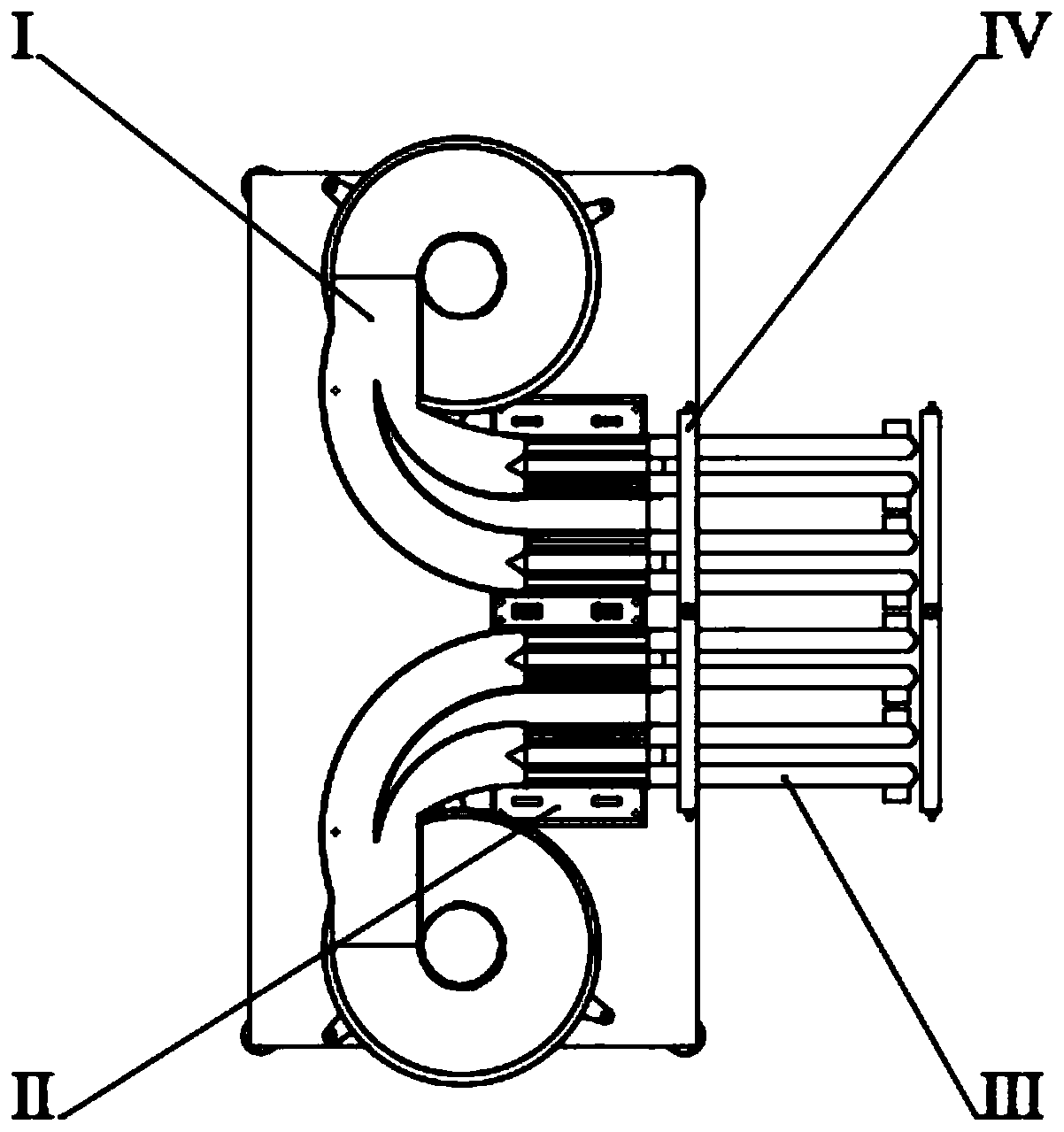

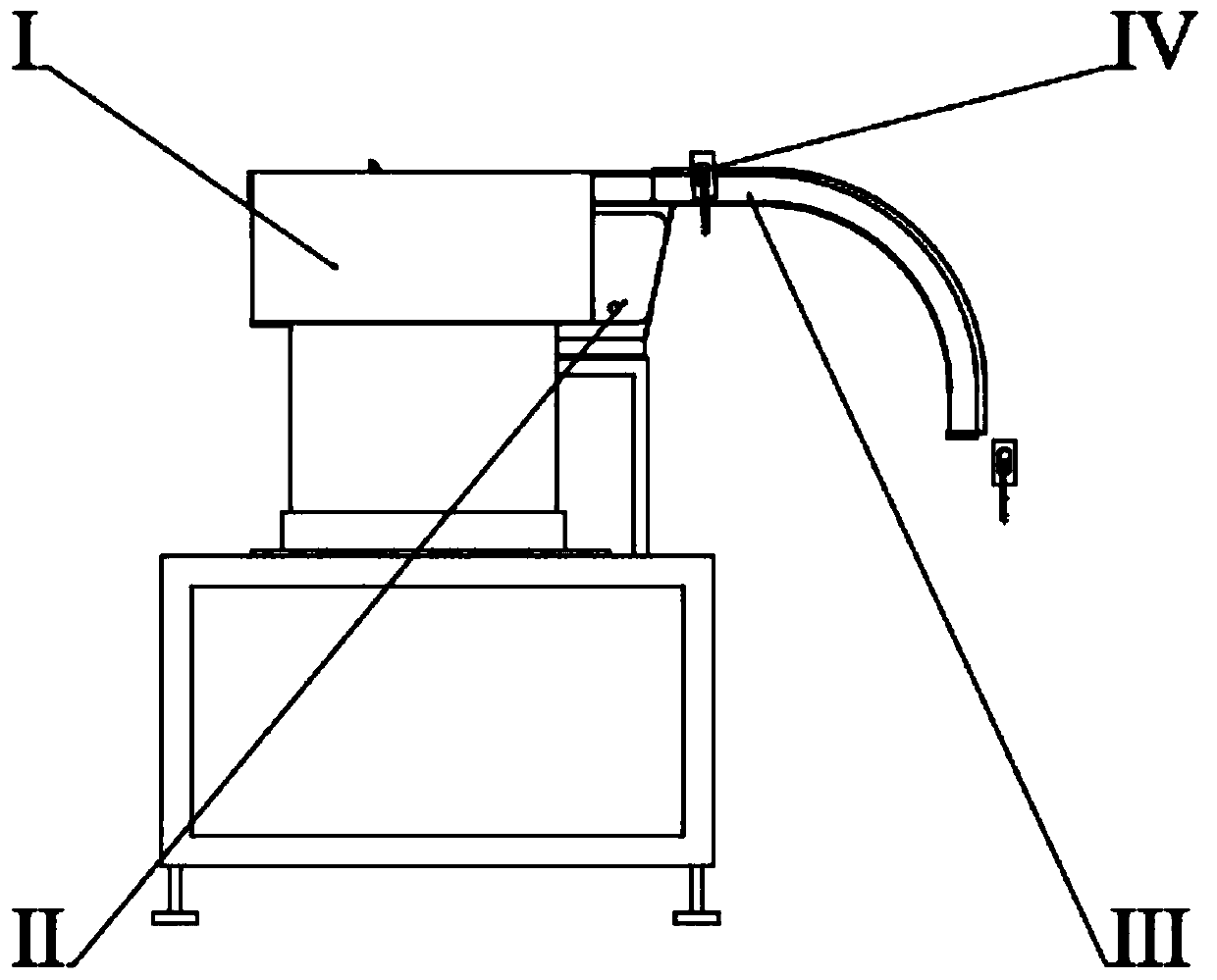

[0058] This embodiment discloses the vibrating plate feeding device of the socket long-diameter cracking equipment, referring to the attached Figure 1-3 As shown, it consists of four parts: vibrating plate device I, direct vibrating device II, material distribution device III, and photoelectric induction device IV. The direct vibrating device II is installed under the V-shaped groove slide of the vibrating plate device I through the direct vibrating frame The V-shaped groove slideway of the vibrating plate device Ⅰ is welded together with the feeding pipe of the distributing device Ⅲ, and the photoelectric sensor device Ⅳ is respectively installed at the entrance of the feeding pipe and directly above the previous row of sockets facing the feeding pipe .

[0059] In an implementation example, the above four parts of the vibrating plate feeding device of the socket long-diameter cracking equipment can include three of them as required, for example, including the vibrating plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com