Epoxy asphalt mastic macadam mixture suitable for airfield pavement and preparation method thereof

A technology of epoxy asphalt and mixture, applied in the field of road building materials, can solve the problems of short time for repairing and paving of airport pavement, insufficient strength and anti-rutting performance, small anti-friction coefficient, etc., and achieves good economic value, Excellent stability and strong anti-deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

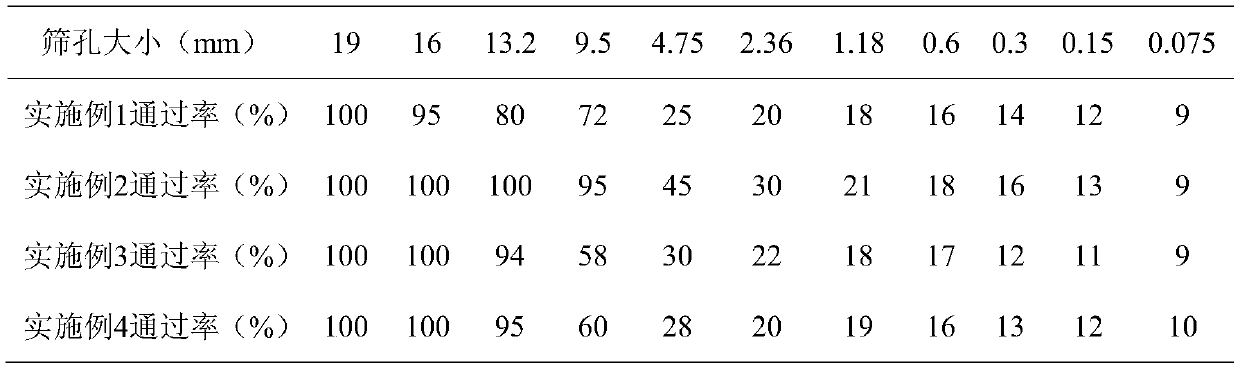

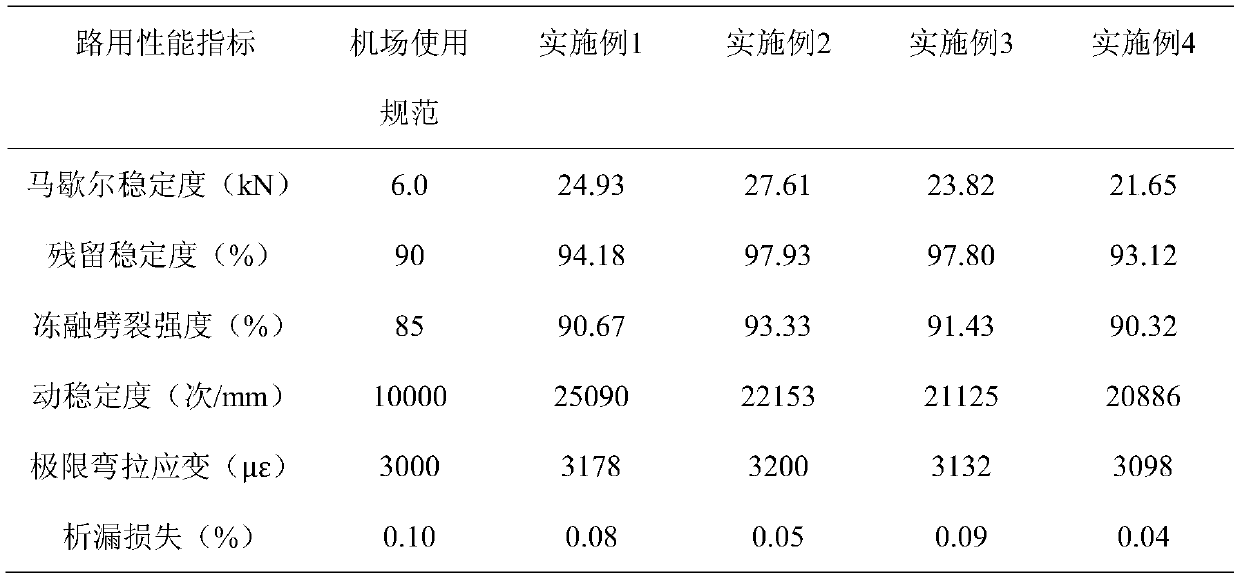

Embodiment 1

[0028] (1) Material preparation

[0029] The epoxy asphalt mastic gravel mixture suitable for airport pavement according to the present invention, in parts by mass, takes 0.7 part of bisphenol A type epoxy resin E-51 (place of origin: Yangzhou Zhongjiang Material Technology Co., Ltd.) , 0.5 parts of modified amine curing agent (origin: Suzhou Kelida Co., Ltd.), 2.9 parts of SBS modified asphalt (origin: Guangzhou Jiabaili Waterproof Engineering Co., Ltd.), 100 parts of mineral material (mineral material is coarse aggregate basalt crushed stone, fine aggregate basalt and slag limestone powder mixture), polyester fiber 0.3 parts. Among them, the mass ratio of bisphenol A epoxy resin E-51 to modified amine curing agent is 1.4, and the mass sum of bisphenol A epoxy resin E-51, modified amine curing agent and SBS modified asphalt is The proportion of ore mass is 4.1%. The mass ratio of basalt gravel and basalt conforms to discontinuous gradation, the maximum nominal particle size...

Embodiment 2

[0038] (1) Material preparation

[0039]The epoxy asphalt mastic gravel mixture suitable for airport pavement according to the present invention, in parts by mass, takes 2.0 parts of bisphenol A epoxy resin E-51 (place of origin: Yangzhou Zhongjiang Material Technology Co., Ltd.) 1.7 parts of modified amine curing agent (origin: Suzhou Kelida Co., Ltd.), 7.5 parts of SBS modified asphalt (origin: Guangzhou Jiabaili Waterproof Engineering Co., Ltd.), 150 parts of mineral material (mineral material is coarse aggregate basalt crushed stone, fine aggregate basalt and slag limestone powder mixture), polyester fiber 0.6 parts. Among them, the mass ratio of bisphenol A epoxy resin E-51 to modified amine curing agent is 1.2, and the mass sum of bisphenol A epoxy resin E-51, modified amine curing agent and SBS modified asphalt is The proportion of ore mass is 7.5%. The mass ratio of basalt gravel and basalt conforms to discontinuous gradation, the maximum nominal particle size is sel...

Embodiment 3

[0045] (1) Material preparation

[0046] The epoxy asphalt mastic macadam mixture suitable for airport pavement of the present invention, in parts by mass, takes 0.8 part of bisphenol A type epoxy resin E-51 (place of origin: Yangzhou Zhongjiang Material Technology Co., Ltd.) , Modified amine curing agent (Origin: Suzhou Kelida Co., Ltd.) 0.8 parts, SBS modified asphalt (Origin: Guangzhou Jia Baili Waterproof Engineering Co., Ltd.) 3.9 parts, Mineral material 110 parts (The mineral material is coarse aggregate basalt crushed stone, fine aggregate basalt and slag limestone powder mixture), polyester fiber 0.4 parts. Among them, the mass ratio of bisphenol A epoxy resin E-51 to modified amine curing agent is 1.0, and the mass sum of bisphenol A epoxy resin E-51, modified amine curing agent and SBS modified asphalt is The proportion of ore mass is 5.0%. The mass ratio of basalt gravel and basalt conforms to discontinuous gradation, the maximum nominal particle size is selected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com