Real-time adjusting device and method for girder line type in bridge pushing process

A real-time adjustment and jacking technology, used in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as ensuring the smooth upper pier and excessive lower deflection of the main girder, reducing construction safety risks and applying span Increased, easy design and construction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

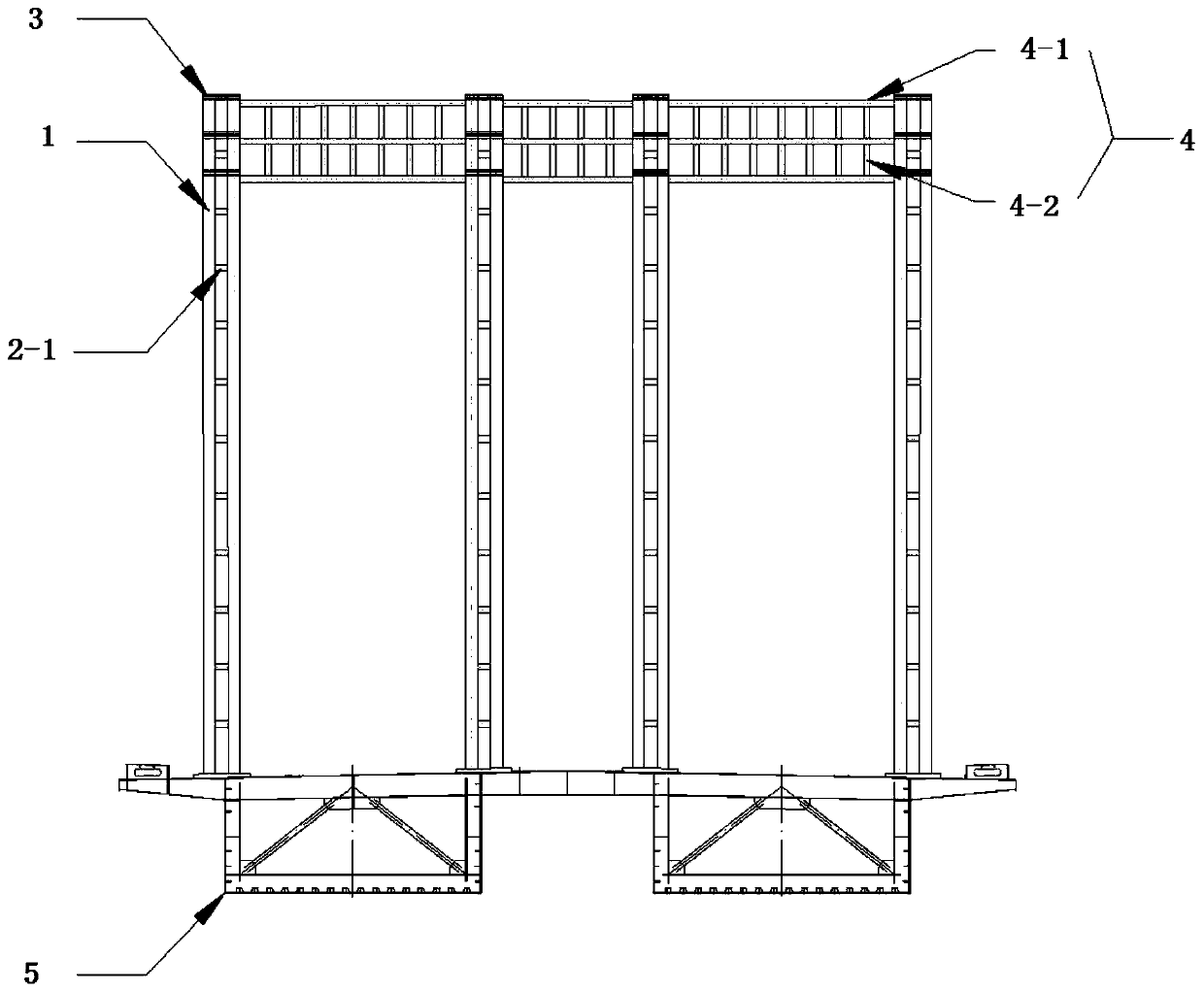

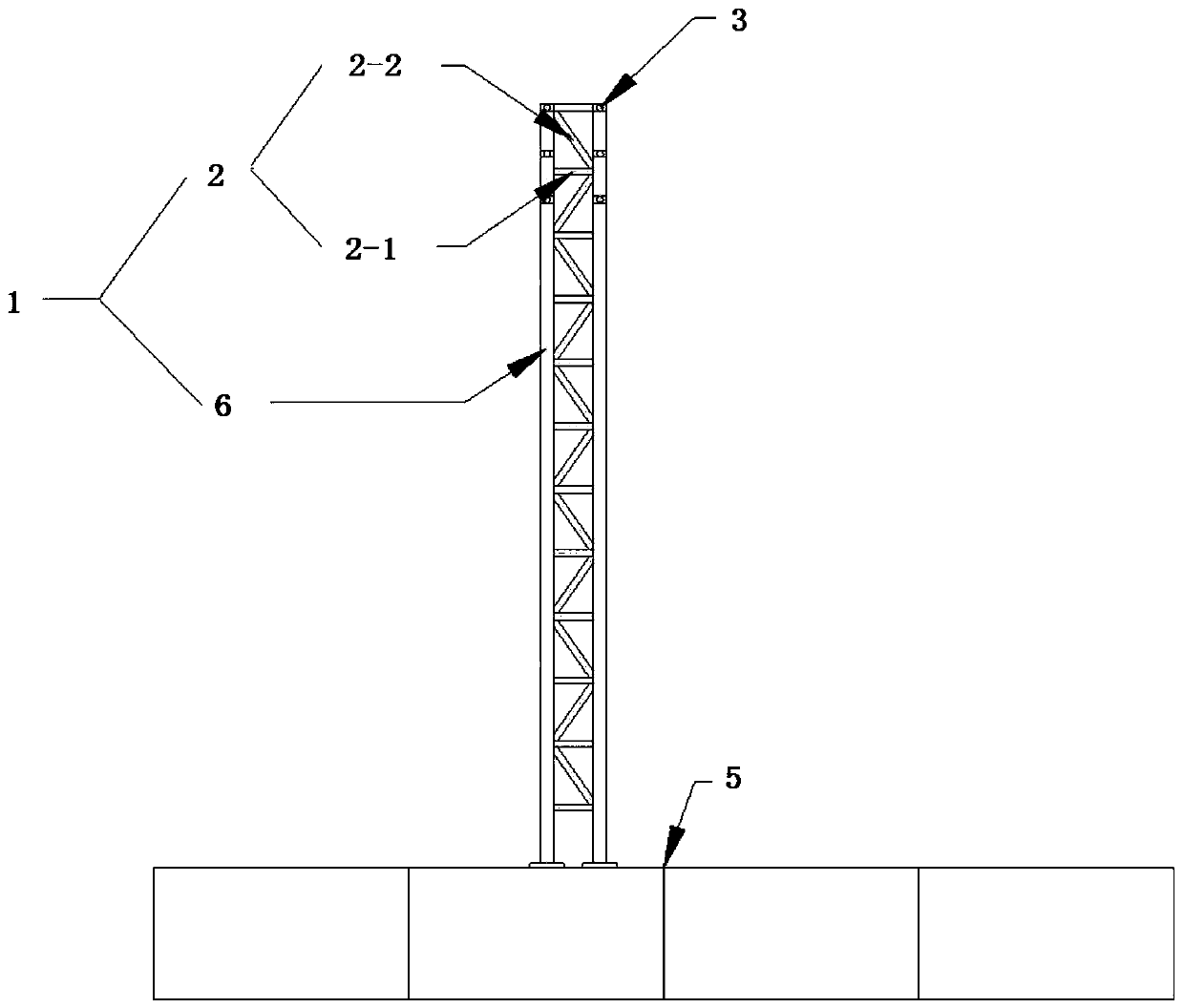

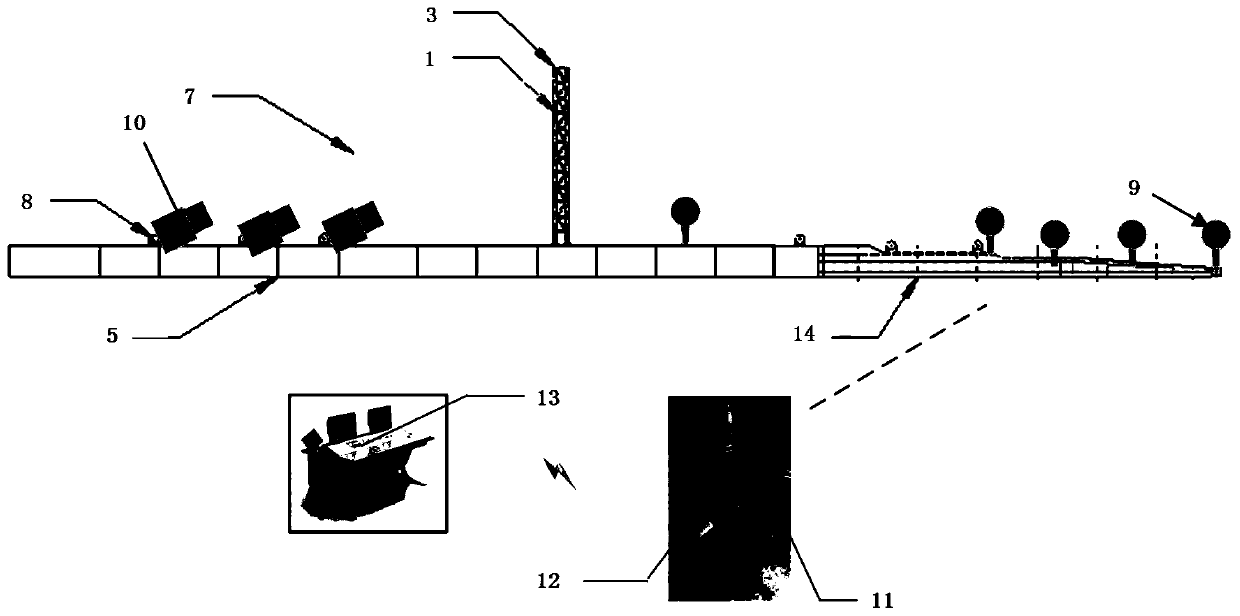

[0039] see Figure 1 to Figure 3 , in a preferred embodiment of the present invention, a device for real-time adjustment of the main girder alignment during the bridge pushing process, including a cable tower 1, a cross-connection between the cable towers 4, a stay cable 7, and a beam body anchoring device 8 , Intelligent tensioning jack 10, automatic linear measurement system, intelligent adjustment system 13.

[0040]The cable tower 1 includes at least two steel pipe columns 6, web members 2 and cable saddles 3, at least two steel pipe risers are arranged at intervals along the width direction of the steel box girder section 5, and the bottom thereof is consolidated with the steel box girder web , in this embodiment, four steel pipe columns 6 are provided, and the height of each steel pipe column 6 is the same, which is 1 / 2.7 to 1 / 3.7 of the maximum span of the bridge. Specifically, the steel pipe column 6 is Φ630mm × 12mm steel pipe. Each steel pipe column 6 is provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com