Sea reclamation area inland river dredging device

A technology of dredging device and inland river, which is used in grain processing, water resource protection, earthmoving machine/shovel, etc. Good effect, high equipment service life, and the effect of improving curing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

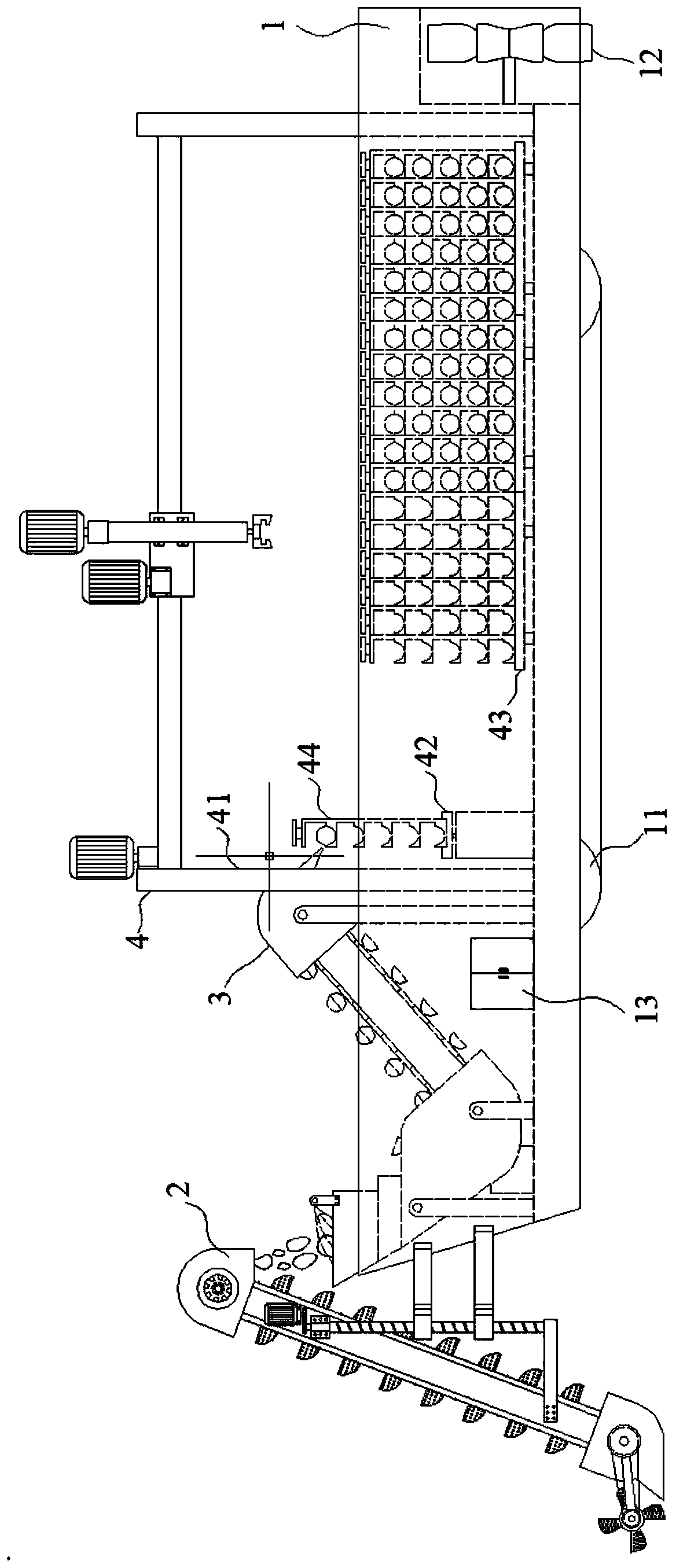

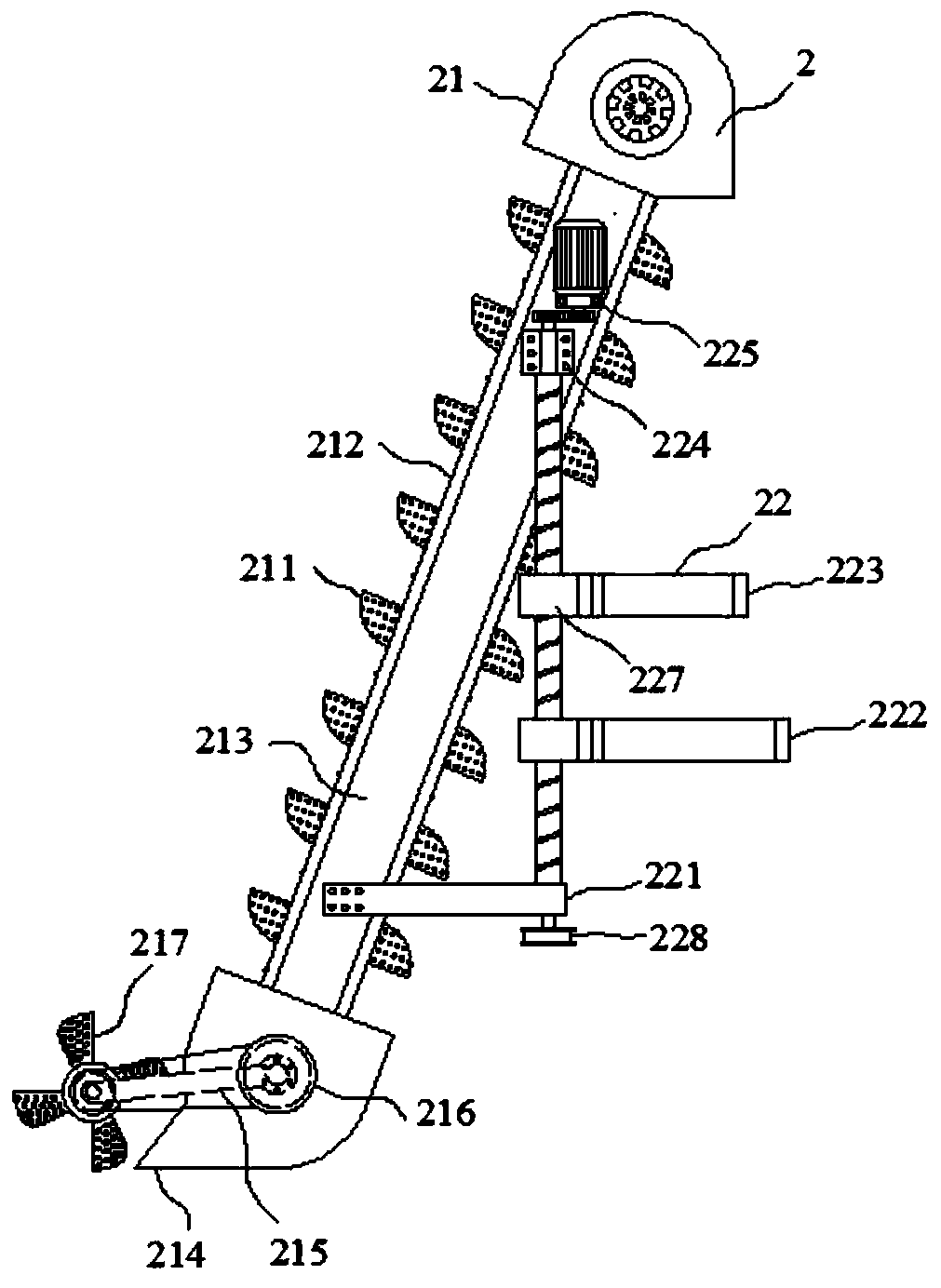

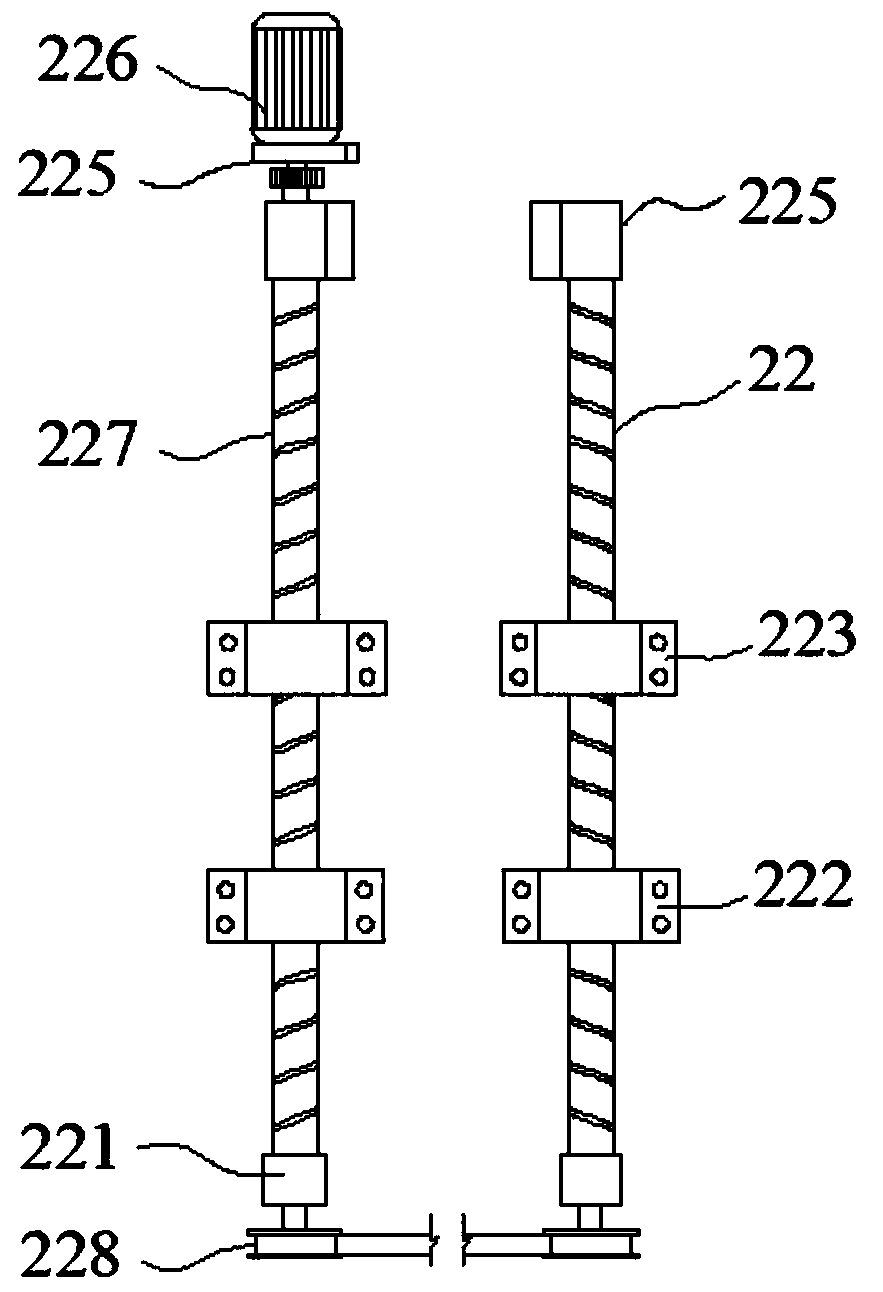

[0036] like Figure 1-7 As shown, the inland river desilting device in the reclamation area includes a loading platform 1, which is characterized in that: the loading platform 1 is a hull, the outer side of the bow is connected with a rotary silt conveying mechanism 2, and the bottom surface of the ship is connected with a stirring mold clamping mechanism 3 and a palletizing mechanism. The transportation mechanism 4; the rotary silt conveying mechanism 2, the stirring mold clamping mechanism 3 and the stacking transportation mechanism 4 are arranged in a line with the symmetrical plane coincident with the symmetric surface of the loading platform 1 and connected end to end; the rotary silt conveying mechanism 2 includes And drive the lifting adjustment mechanism 22 that the rotary silt conveying mechanism 2 moves up and down as a whole; the stirring mold clamping mechanism 3 includes a stirring spraying mechanism 31 and a mold clamping mechanism 32, and the stirring and sprayin...

Embodiment 2

[0057] When the inland river dredging device in the surrounding sea area of the present invention is actually used, the hull loading platform 1 can move on land under the action of the propulsion mechanism 11 to carry out dredging work; Satisfied with amphibious, wide range of applications. Select the moving method according to the sea and land conditions to move the loading platform 1 to the operation area, drive the lifting adjustment mechanism 22 to adjust the height of the hoist 21 to the designated position according to the water depth and dredging height setting, and the hoist 21 drives the spinning silt mechanism at the same time 217 for dredging and conveying work; at the same time, the cavity 311 of the spraying mechanism 31 is stirred to connect the upper layer of the silt to the silt blanking, and the spraying mechanism 312 sprays the soil curing agent, and the spraying direction of the nozzle can be adjusted to fully cover, and the curing agent is pumped The box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com