Refrigerator

A refrigerator and sealing cavity technology, applied in the field of home appliances, can solve problems such as long control lines, and achieve the effects of good heat absorption, cost reduction, and slow flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

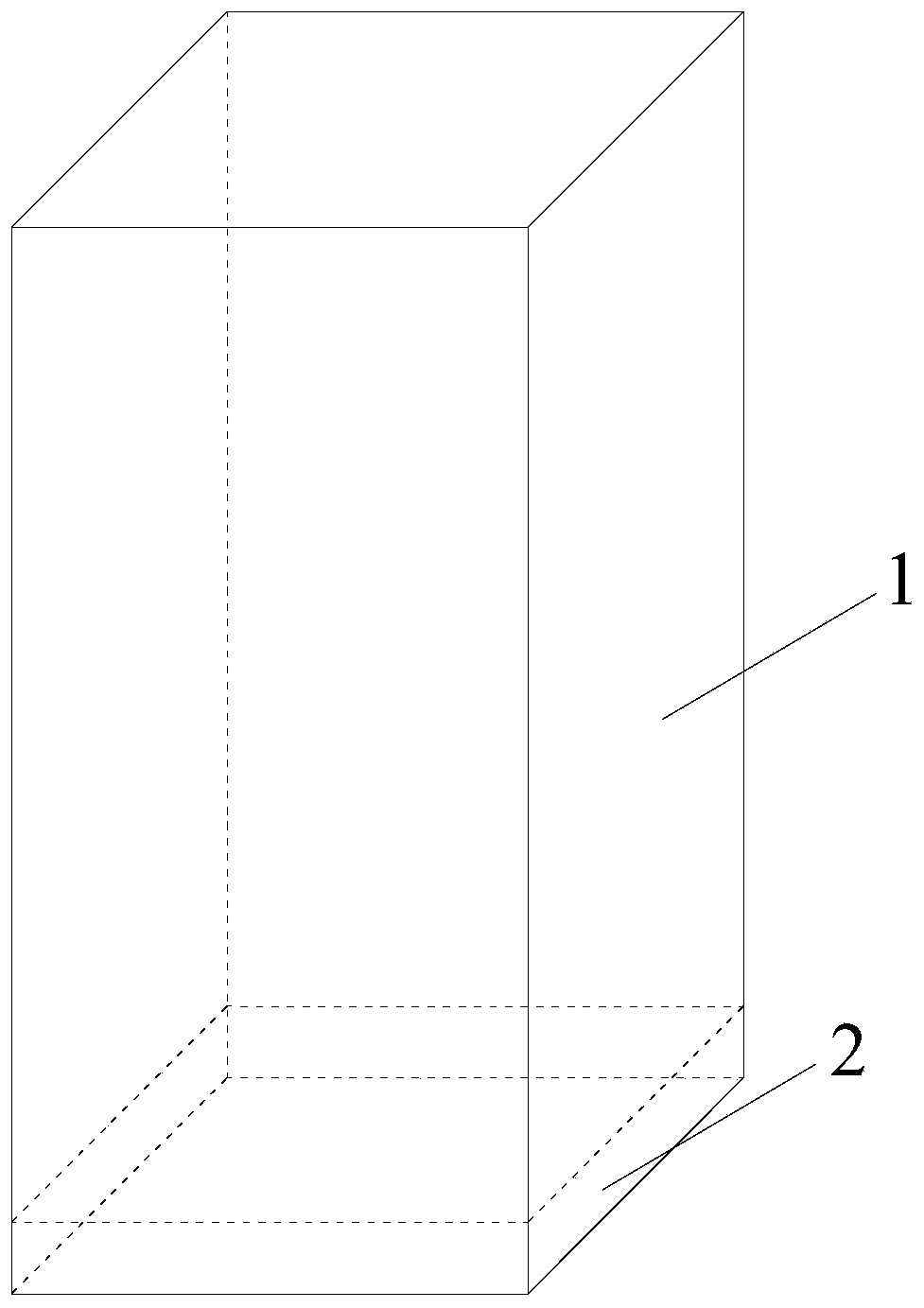

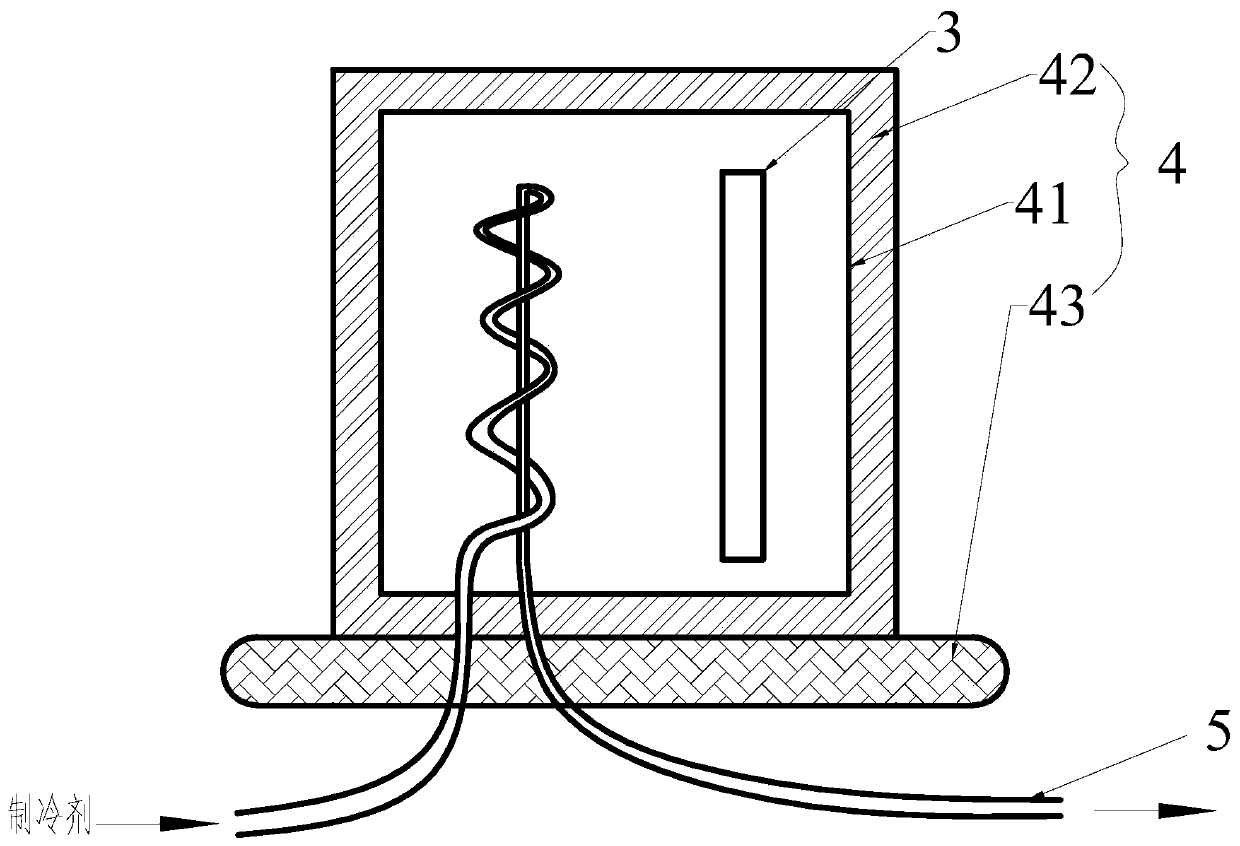

[0036] see figure 1 and figure 2 , The refrigerator of this embodiment includes a casing 1, a compressor (not shown), a control panel 3, and an installation structure 4.

[0037] Various electronic devices are installed on the control panel 3, and these electronic devices are mainly used to form a control system for controlling the operation of the refrigerator, such as controlling the operation of the compressor.

[0038] The bottom of casing 1 is provided with compressor cabin 2, and compressor, control board 3, installation structure 4 are all installed in compressor cabin 2. The temperature in the compressor compartment 2 is relatively high due to the operation of the compressor, often higher than 50°C, which exceeds the ambient temperature requirements of each electronic device on the control board 3.

[0039] The present invention enables the control panel 3 to be installed in the compressor compartment 2 by designing the installation structure 4 , thereby changing th...

Embodiment 2

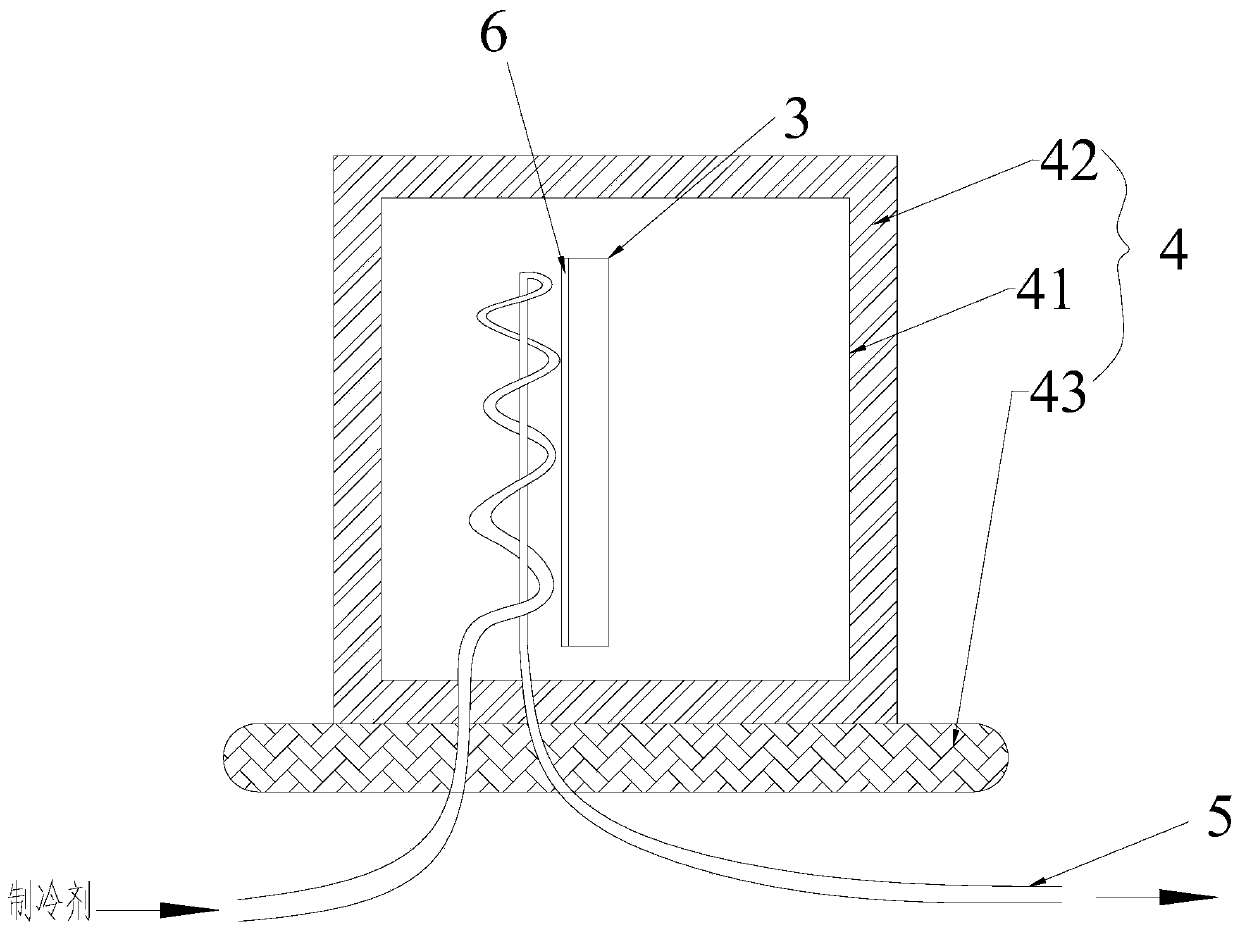

[0049] see image 3 The difference between this embodiment and Embodiment 1 is that: the side of the control board 3 facing the return pipe 5 is provided with a thermally conductive insulating layer 6, such as a high thermally conductive insulating layer made of high thermally conductive insulating composite powder. The main components of high thermal conductivity insulating composite powder are nano-silicon magnesium nitride, nano-silicon carbide, nano-aluminum nitride, nano-boron nitride, high-sphericity alumina, nano-silicon nitride (regular orientation structure), etc. The combination of fillers, according to the particle size, shape, surface wettability, doping fraction, and thermal conductivity of each material, use particles with different particle sizes to form the largest packing degree between the fillers and make the system The heat conduction network in it is formed to the greatest extent to achieve effective heat conduction and obtain a high heat conduction system...

Embodiment 3

[0052] The difference between this embodiment and Embodiment 1 is that the spiral structure is positioned in the sealed cavity 41 through a metal heat conducting sheet. Thereby, the present invention is easier to realize, plays a better positioning effect on the spiral structure, and the installation in the sealed cavity 41 is also more convenient and free. The metal heat conducting sheet can be a rectangular sheet parallel to the control board 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com