Free boundary simulation system for modal test

A modal test and simulation system technology, applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve problems such as low cost performance, hidden safety hazards, self-heavy, etc., and achieve strong expansion ability and flexibility Large, adaptable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In addition to the embodiments described below, the invention can be embodied in other embodiments or carried out in different ways. It is, therefore, to be understood that the invention is not limited to the details of construction of the components described in the following description or shown in the drawings. While only one embodiment is described here, the claims are not limited to that embodiment.

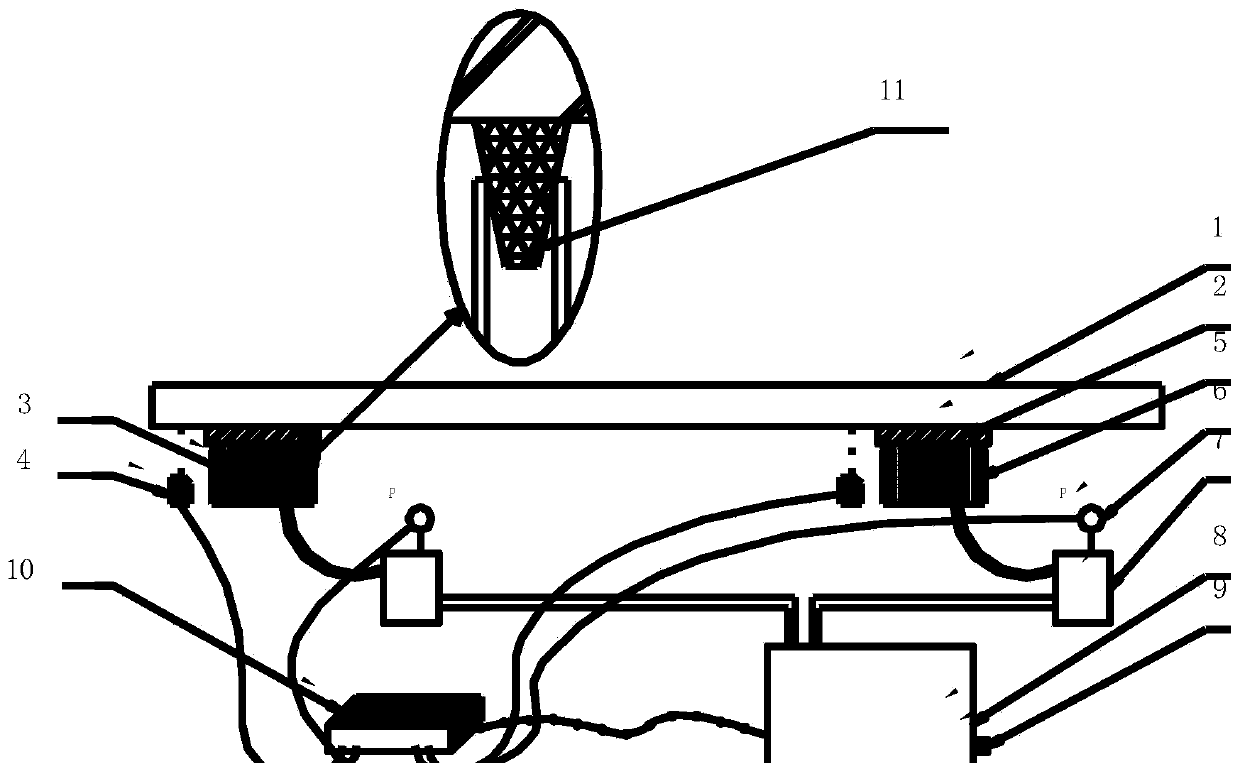

[0020] Such as figure 1 As shown, a free boundary simulation system for modal tests in the present invention includes a tested product 1, an adapter tool 2, an air bag 3, a displacement sensor 4, a limit mechanism 5, a pressure sensor 6, an additional air chamber 7, an air Road console 8, total road interface 9, boundary simulation controller 10, frustum structure 11.

[0021] The limit mechanism 5 is symmetrically arranged on the airbag 3 twice, and the limit mechanism 5 and the airbag 3 are arranged under the product bearing structure. When not working, the tested...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com