Supercharger test bench combustion chamber air inflow proportion adjusting device and method

A technology of test bench and proportional adjustment, which is applied in the direction of measuring devices, machine/structural component testing, instruments, etc., can solve the problems of wasting fuel, polluting the atmosphere, incomplete combustion of fuel, etc., to reduce fuel consumption and protect the environment , the effect of saving fuel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

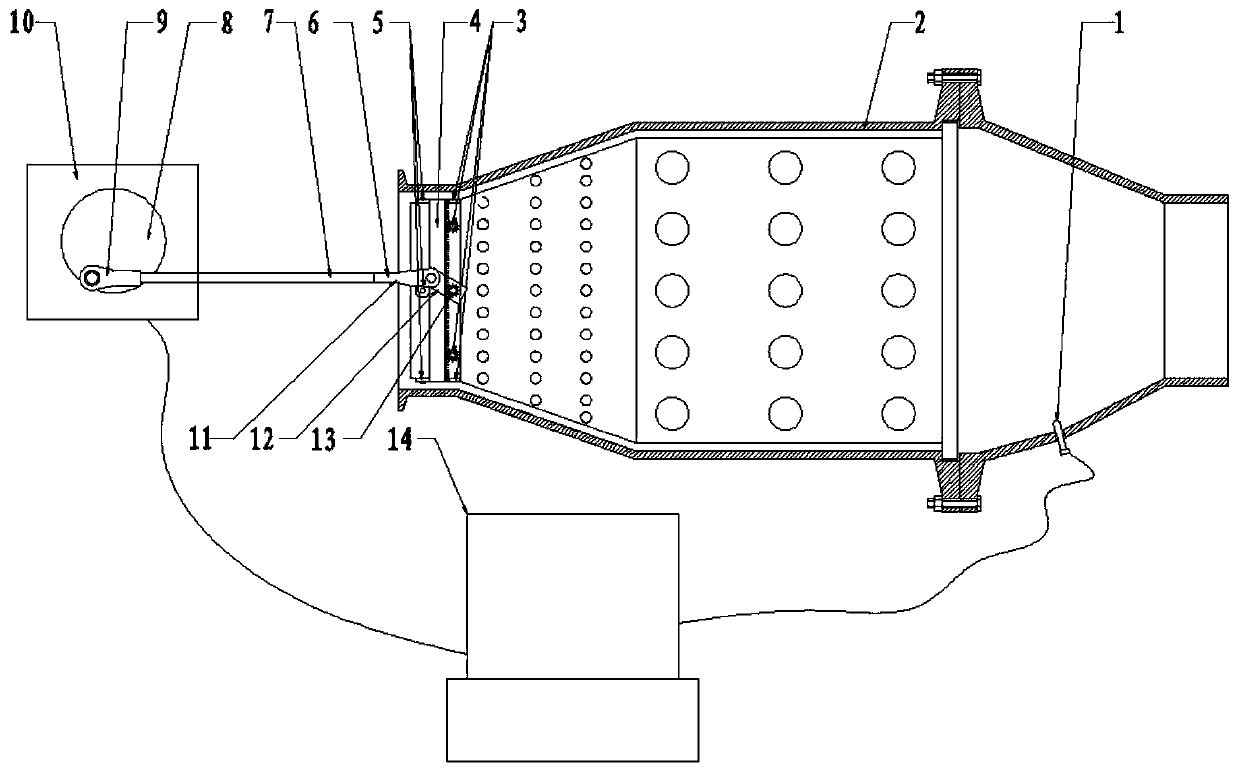

[0034] see figure 1 , shown in the figure is a device for adjusting the intake air volume of the combustion chamber of the supercharger test bench, including a control device 14, a gas detector 1, a stepping motor 10, a crank connecting rod mechanism, a driving gear 13, a gear Transmission mechanism 4 and several driven gears 3.

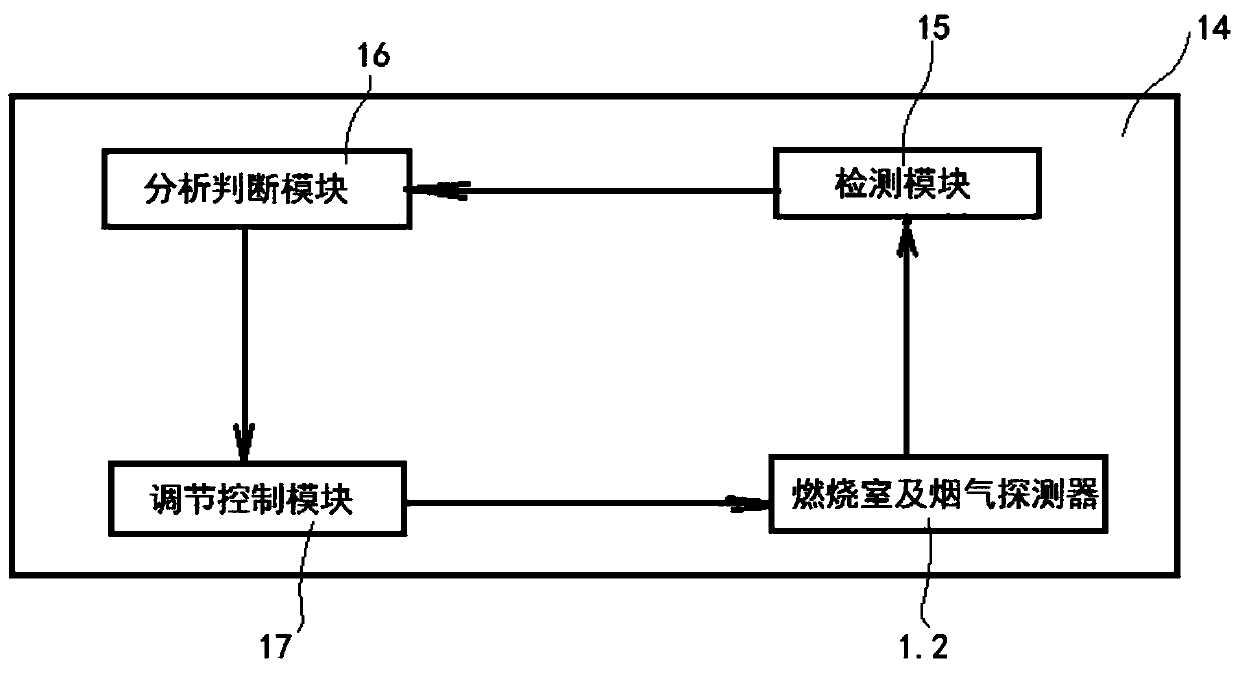

[0035] see figure 2 , the control device 14 is an industrial control computer, which includes a detection module 15, an analysis and judgment module 16, and an adjustment control module 17 in the industrial control computer. The input end of the detection module 15 is connected to the gas detector 1 signal, and the signal output end of the detection module 15 is connected to The signal input end of the analysis and judgment module 16 is connected, the signal output end of the analysis and judgment module 16 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com