Cold chain distribution system and method for distributing or selling products and low-temperature milk by using cold chain distribution system

A cold chain and low-temperature technology, which is applied to the cold chain distribution system and the field of distribution or sales of products and low-temperature milk using the cold chain system, which can solve the problems of increased distribution costs and risks, difficult storage, and long time consumption, and improve convenience and flexibility, avoiding temperature rise and deterioration, and improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

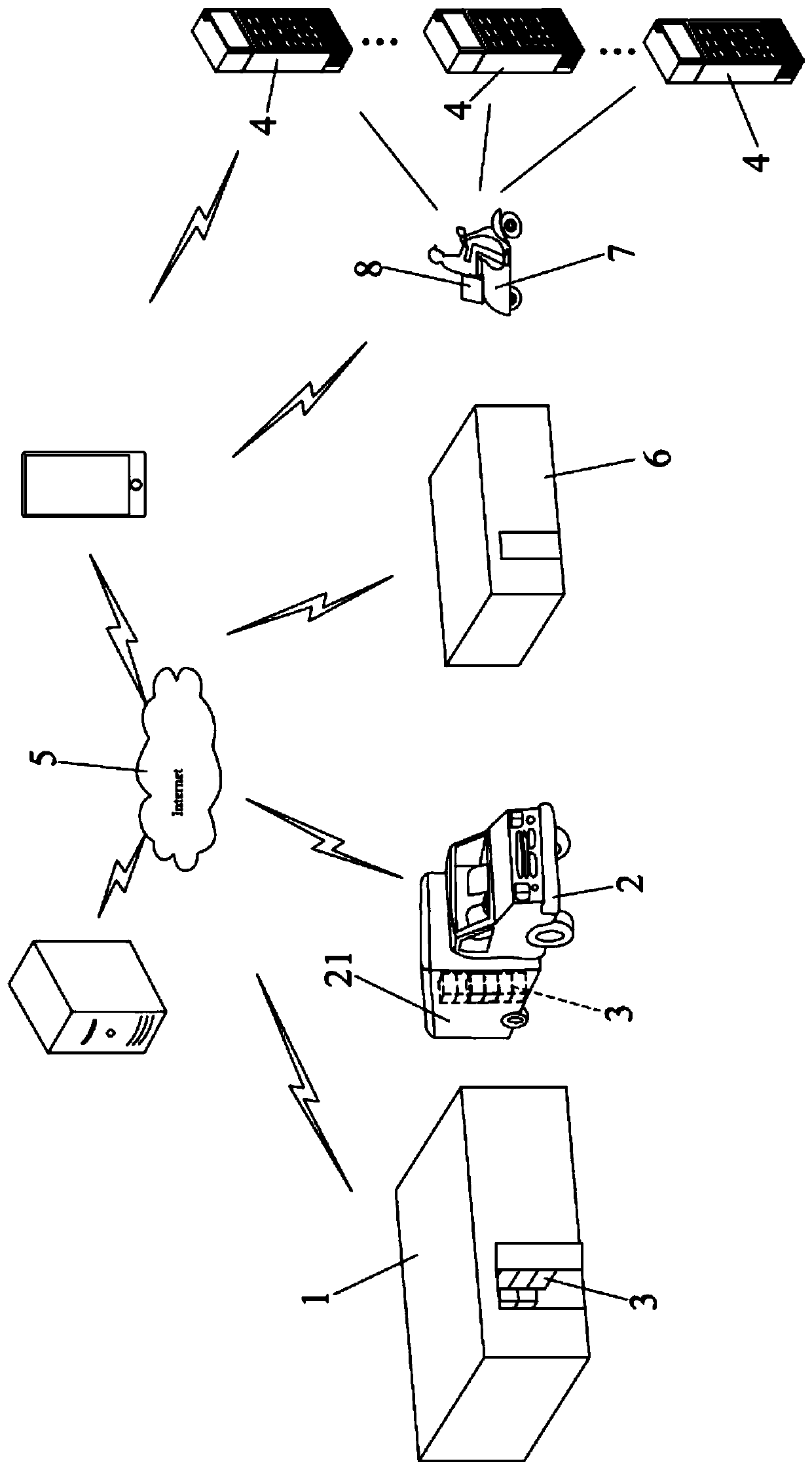

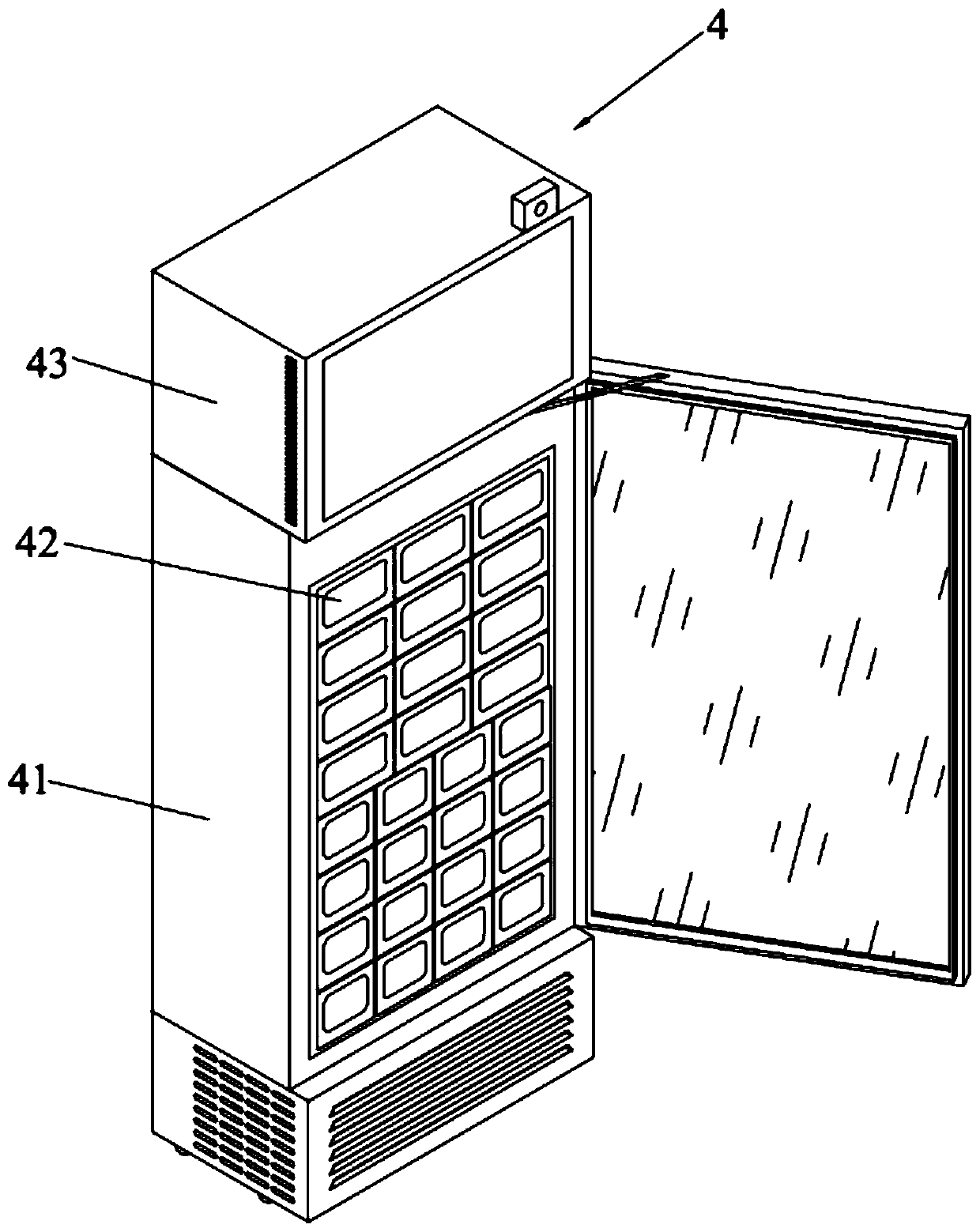

[0051] Such as figure 1 and figure 2 As shown, the present invention discloses a cold chain distribution system, which at least includes a discharge refrigerator 1, a transport vehicle 2 with a refrigerator compartment 21, a plurality of storage boxes 3, a self-service refrigerator 4, and a cloud server 5. The storage boxes 3 are removably placed in the discharge refrigerator 1 or the refrigerated compartment 21, and each storage box 3 is equipped with a temperature-sensing locator 31, and the temperature-sensing locator 31 is connected to the cloud server 5 through a communication module. The refrigerated cabinet 4 is installed in the distribution terminal. The self-service refrigerated cabinet 4 includes a box body 41, a plurality of unit grids 42 arranged in the box body 41, a refrigeration module 43 conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com