Plane equal-radius circular region division radius determination method based on orthodontic arch wire bending point density

A technology for orthodontic arch wire and determination method, which is applied in the fields of arch wire, orthodontics, medical science, etc., can solve the problem of affecting the bending accuracy of personalized orthodontic arch wire, the bending sequence of unreasonable forming control points, and the influence of orthodontic treatment Effect and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

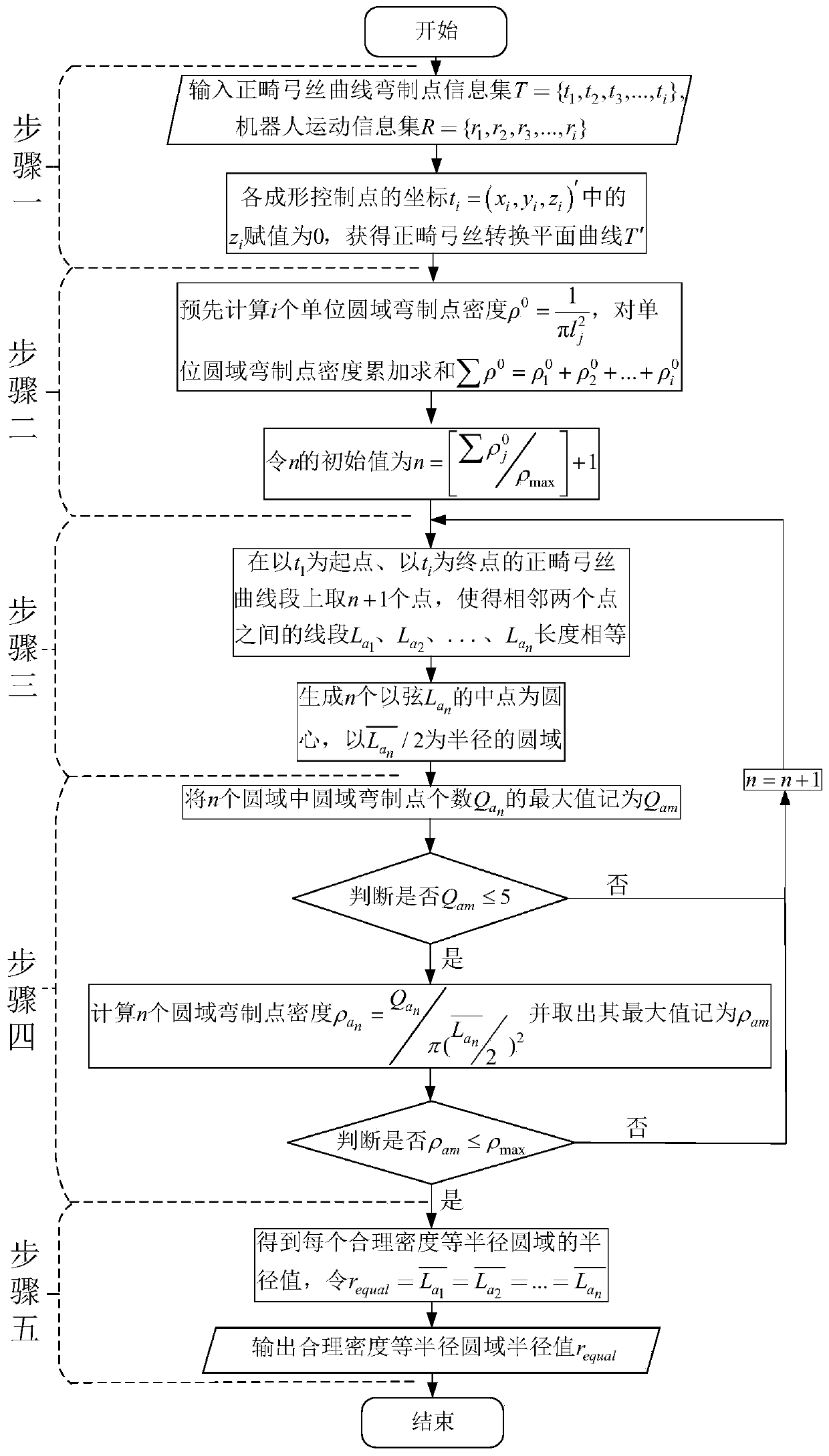

[0038] Embodiment 1: as figure 1 , figure 2 , image 3 , Figure 4 As shown, this specific embodiment adopts the following technical solutions: a method for determining the radius of a plane equal-radius circle domain division based on the density of orthodontic archwire bending points, and the specific implementation process of the method is:

[0039] Step 1, Equal radius determination of circle division data import and orthodontic archwire curve conversion:

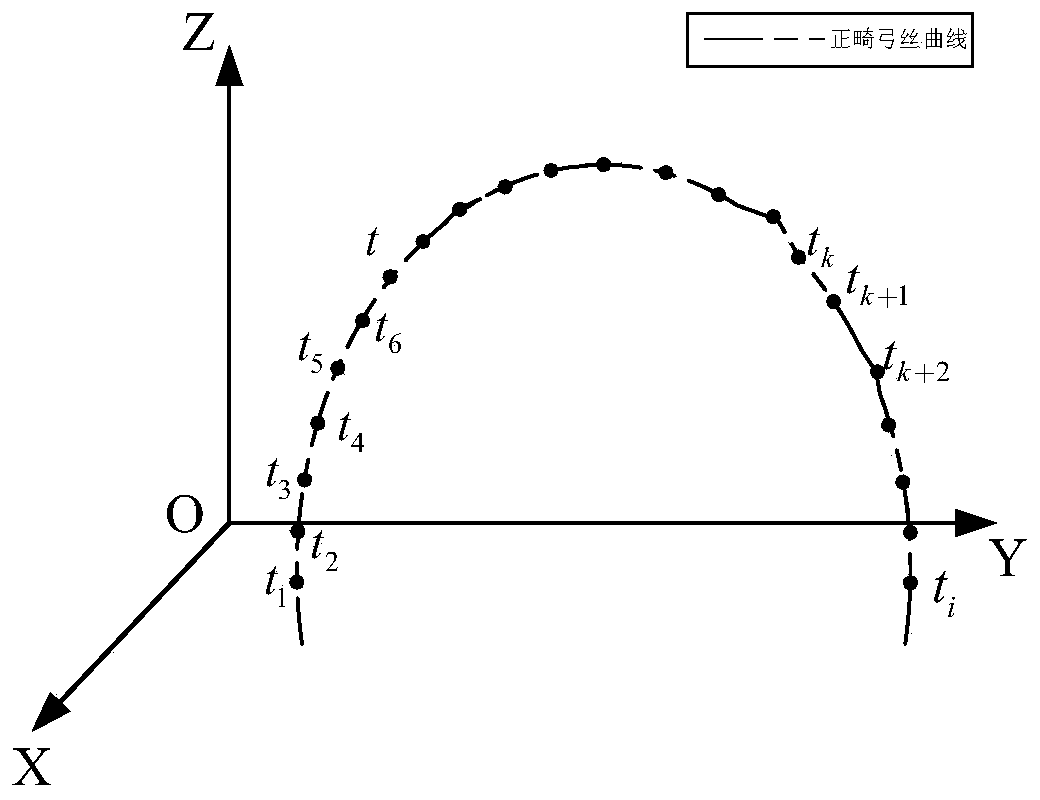

[0040] According to the orthodontic archwire curve with i bending points of the patient, calculate and input the orthodontic archwire curve bending point information set T={t 1 , t 2 , t 3 ,...,t i},t i =(x i ,y i ,z i )' is the coordinates of each orthodontic archwire curve bending point, at each bending point t i The upper robot performs different bending movements, each orthodontic archwire curve bending point t i Each corresponds to a bending point robot bending information unit r i , the robot bending i...

Embodiment 2

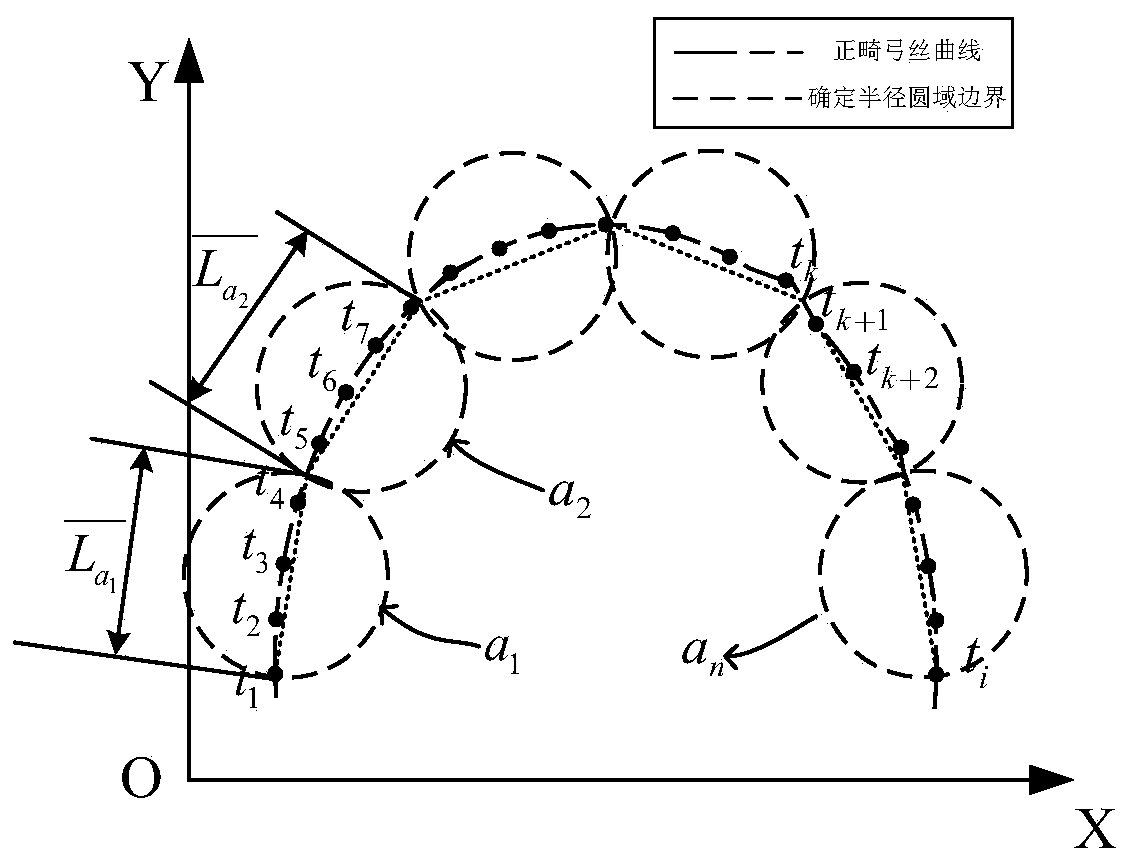

[0059] Embodiment 2: as figure 2 As shown, there is a personalized orthodontic archwire curve containing i=22 bending points, and the angle-to-distance ratio of all bending points is E j are not greater than the specified upper limit E of the angle-to-distance ratio of the bending point max , in the process of determining the radius of the personalized orthodontic archwire curve based on the bending point density of the plane equal-radius circle domain division, such as image 3 As shown, assuming that through the calculation of step two, it can be known that n=6 equal-radius circle domains are determined for the first trial, and step three is continued to define the center and radius of the six equal-radius circle domains for the first trial division, and in the orthodontic bow Generate 6 circles with the same radius on the silk curve to divide the bending points, and carry out step 4 to verify the obtained results. When n=6, the circles with the same radius are determined to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com