a hip prosthesis

A hip joint prosthesis and acetabular technology, applied in the field of hip joint replacement, can solve the problems of increasing patient pain, small sidewall compression, wear of acetabular lining, etc., and achieve the effect of reducing the difficulty of surgery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

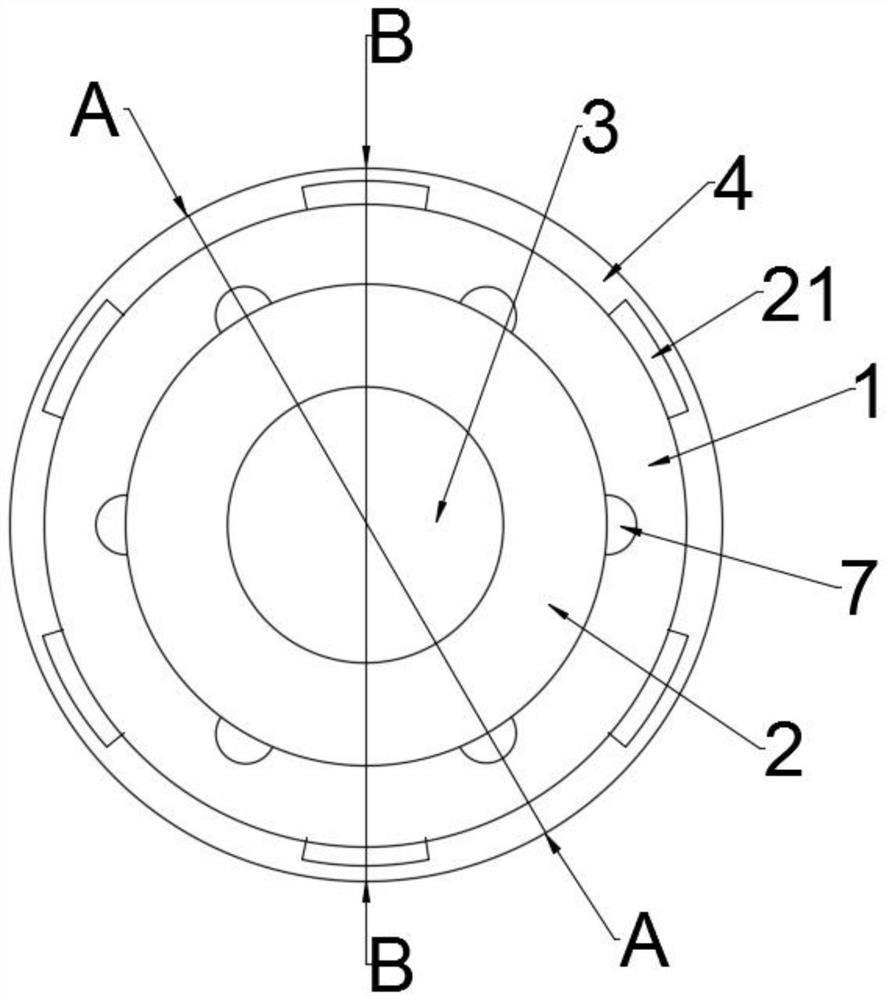

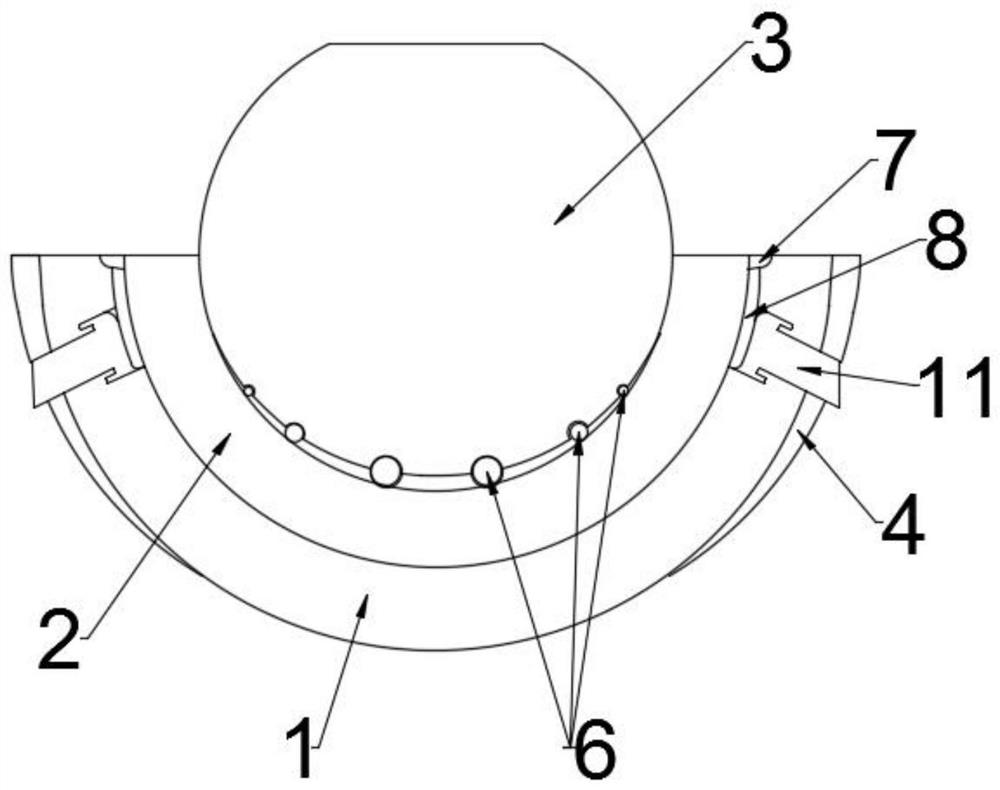

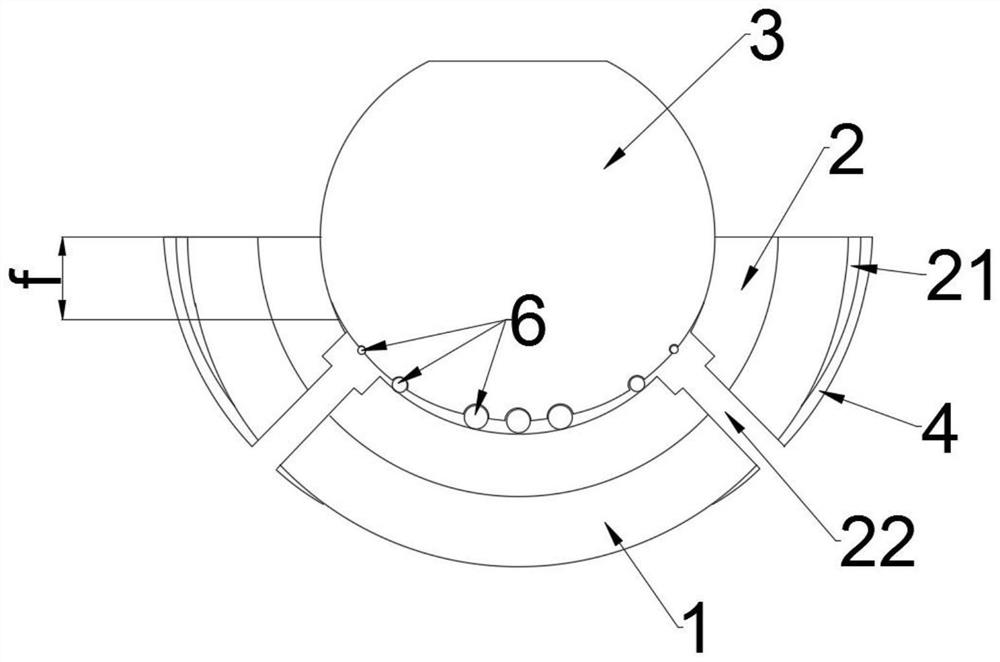

[0032] Example: see Figure 1-14 , in the present invention, a hip joint prosthesis includes an acetabular outer cup 1, an acetabular lining 2, and a ball head 3. The acetabular outer cup 1 is a hemisphere for placing in the acetabular fossa of a human body, and the traditional acetabular cup The outer cup is the same, the acetabular lining 2 is a hemisphere, the same as the traditional acetabular lining, made of ultra-high molecular polyethylene material, the ball head 3 is an irregular sphere, the same material as the traditional ball head, the ball head 3 in the shape of Figure 4 As shown, wherein the hypothetical line 23 does not exist, the hypothetical line 23 is a line of a regular sphere, the shape of the lower end of the ball head 3 is an ellipsoid, and the outer side of the acetabular cup 1 is provided with a thickened cover 4, which is Hemispherical annular structure with an open lower end, namely Figure 12 As shown, the acetabular lining 2 is located inside the ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com