Desktop-level 3D printing equipment

A 3D printing, desktop-level technology, applied in the field of 3D printing, can solve the problems of narrow use range of parts, low degree of automation, poor printing effect, etc., and achieve the advantages of easy motion control precision detection, high space utilization, and reduced energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

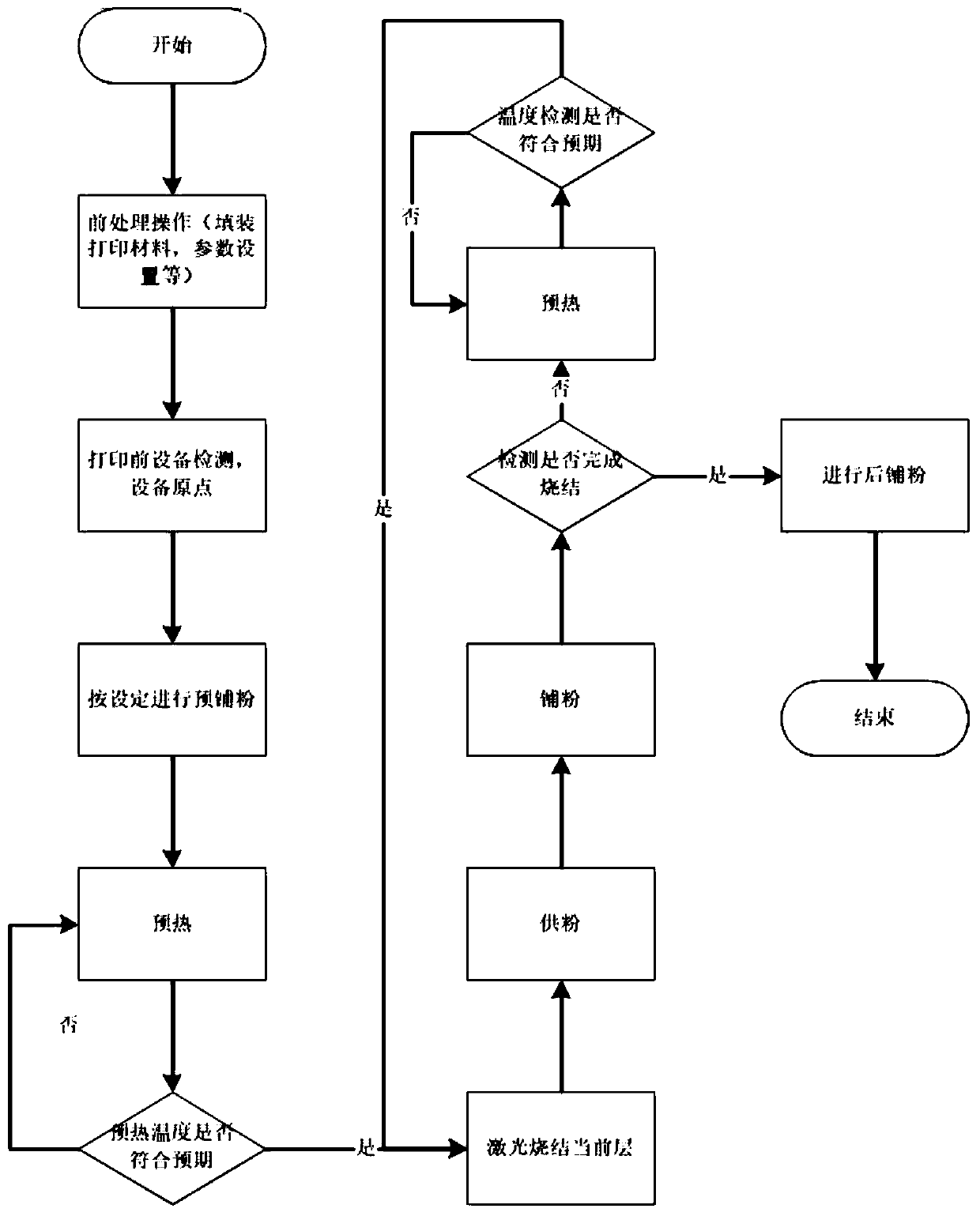

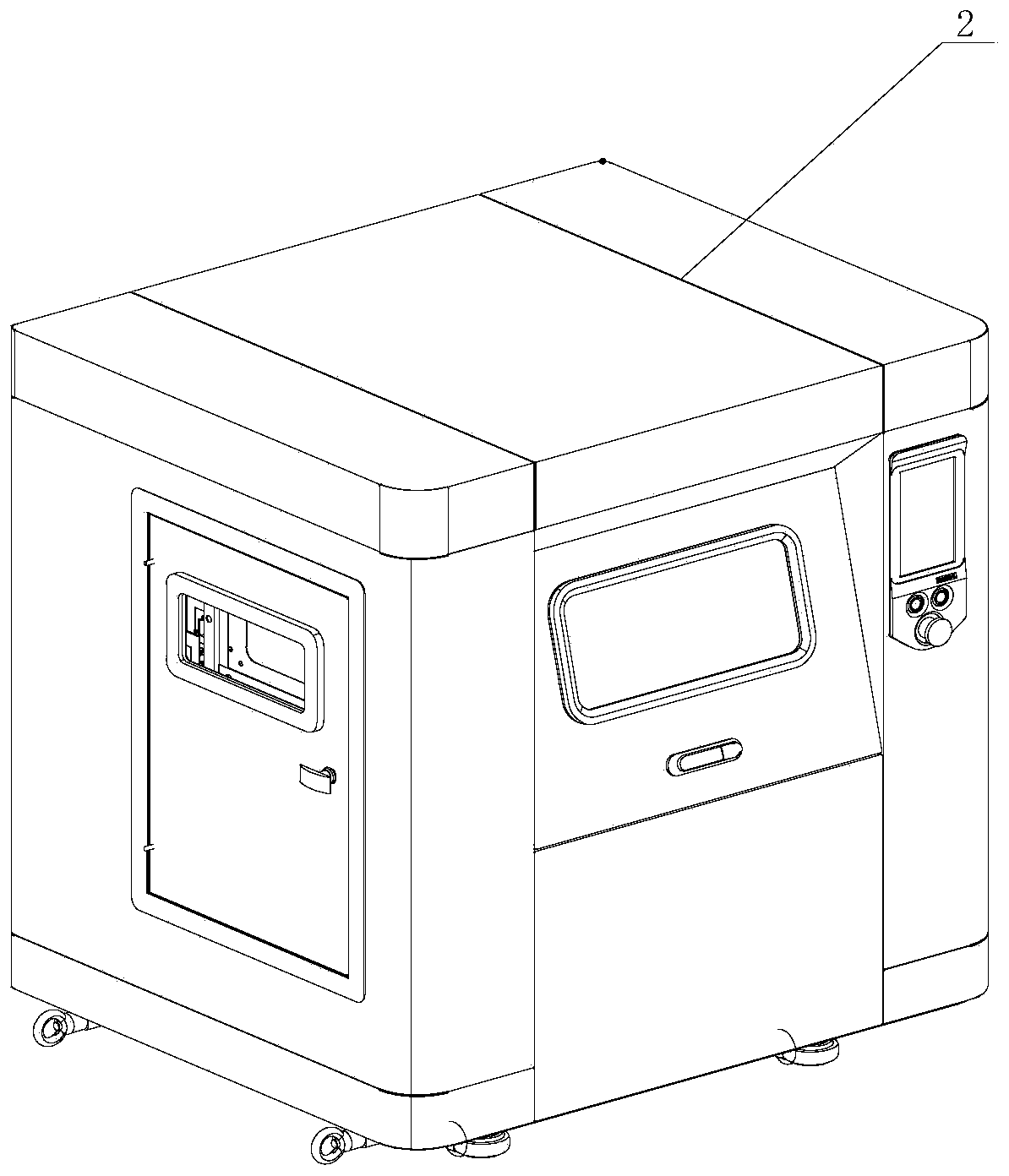

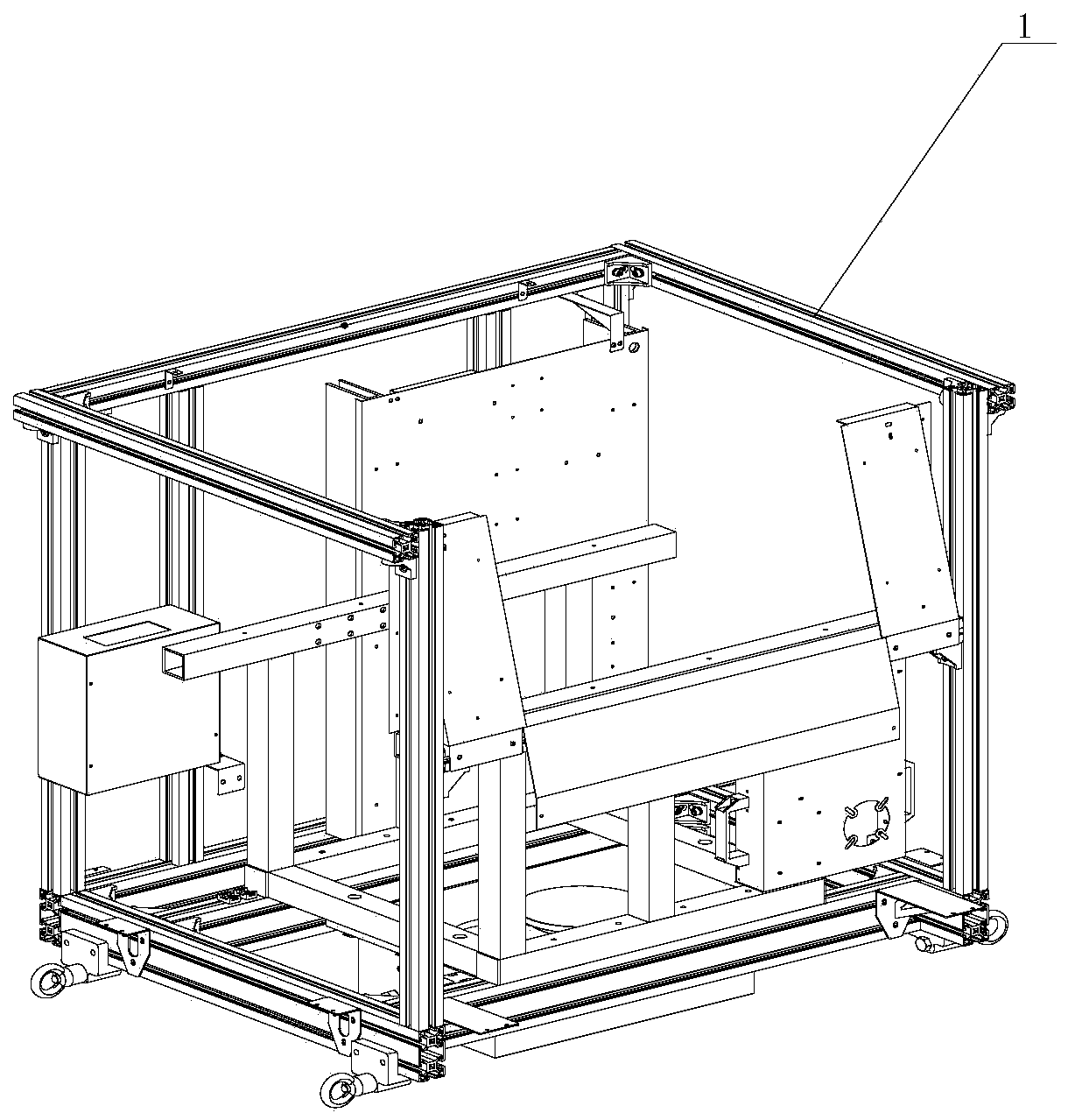

[0036] Specific implementation mode one: combine Figure 1 to Figure 3 Describe this embodiment, a desktop 3D printing device described in this embodiment includes a frame 1 and a casing 2, and the casing 2 is set on the frame 1; the desktop 3D printing device also includes an optical path mechanism 3 , the sealing heating mechanism 4, the powder supply mechanism 5 and the powder spreading mechanism 6, the optical path mechanism 3, the sealing heating mechanism 4, and the powder supply mechanism 5 are sequentially installed in the frame 1 from top to bottom, and the powder spreading mechanism 6 is installed in the sealing heating mechanism 4 within.

specific Embodiment approach 2

[0037] Specific implementation mode two: combination Figure 4 with Figure 5To illustrate this embodiment, the optical path mechanism 3 of a desktop-level 3D printing device described in this embodiment includes a laser bracket 3-1, an optical path bracket 3-2, a laser tube 3-3, an optical path assembly, a dust cover 3-4 and The dust-proof connector 3-5 in the middle of the optical path, the laser bracket 3-1 is installed vertically in the frame 1, the upper end of the laser bracket 3-1 passes through the dust-proof connector 3-5 in the middle of the optical path and the rear end of the optical path bracket 3-2 connected, the optical path assembly is installed on the optical path bracket 3-2, and the optical path assembly is located above the sealing heating mechanism 4, the laser tube 3-3 is vertically installed in the laser bracket 3-1, and the dust cover 3-4 Set on the optical path assembly. The structure is independent, simple and compact, the difficulty of installation...

specific Embodiment approach 3

[0038] Specific implementation mode three: combination Figure 4 with Figure 5 To illustrate this embodiment, the optical path assembly of a desktop-level 3D printing device in this embodiment includes a reflector 3-6, a beam expander 3-7, a vibrating mirror 3-8, and a field mirror 3-9, and the reflector 3-6, the beam expander 3-7, and the vibrating mirror 3-8 are installed on the optical path support 3-2 in sequence from back to front, and the reflector 3-6 is located above the dustproof connector 3-5 in the middle of the optical path. The mirror 3-9 is installed on the lower surface of the vibrating mirror 3-8, and the field mirror 3-9 is located above the sealing heating mechanism 4. The laser quality is improved through beam expansion and focusing, the manufacture and assembly is simple, the cost is low, the sealing effect is provided, and the cleaning cycle of the optical path lens is prolonged. Other components and connections are the same as those in the second embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com