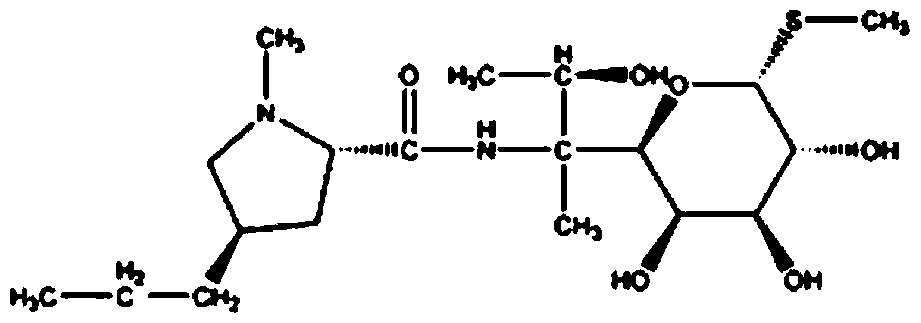

Method for treating butanol crystallization mother liquor of lincomycin hydrochloride

A technology of lincomycin hydrochloride and treatment method, which is applied in the field of pharmacy, can solve problems such as difficulties, inability to guarantee product quality, low recovery rate of lincomycin hydrochloride, etc., and achieve the effect of simple recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The processing method of the butanol crystallization mother liquor of lincomycin hydrochloride, the processing method comprises:

[0024] (1) Add 200ml of saturated sodium phosphate to 10000ml of lincomycin hydrochloride butanol crystallization mother liquor, then add 5000ml of water, then adjust the pH value to 8.4 with sodium hydroxide; stir well, and let it stand for 1 hour Layered to obtain supernatant and lower turbidity, and then separated;

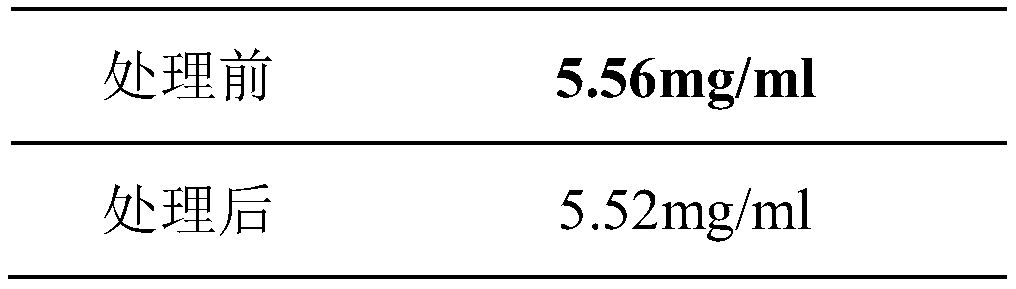

[0025] (2) the turbid liquid of above-mentioned separation is carried out centrifugation, obtains liquid and solid; Detect lincomycin hydrochloride in supernatant with high performance liquid chromatography, detection result is as shown in lincomycin hydrochloride content in table 1 mother liquor , the supernatant is used to recover lincomycin hydrochloride; and

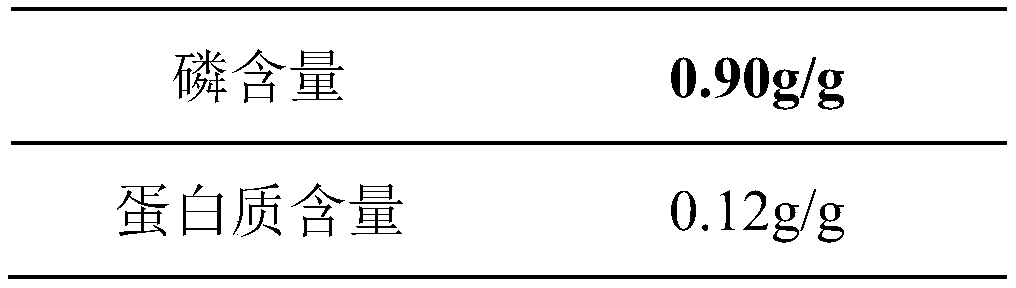

[0026] (3) The solid obtained in step (2) is dried. The small test is dried in an oven at 95°C under normal pressure. In production, boiling drying can be used. Th...

Embodiment 2

[0040] The processing method of the butanol crystallization mother liquor of lincomycin hydrochloride, the processing method comprises:

[0041] (1) Add 600ml of saturated sodium phosphate to 20,000ml of lincomycin hydrochloride butanol crystallization mother liquor, then add 20,000ml of water, then adjust the pH value to 9.0 with sodium hydroxide; stir well, and let stand for 1 hour Layered to obtain supernatant and lower turbidity, and then separated;

[0042] (2) the turbid liquid of above-mentioned separation is carried out centrifugation, obtains liquid and solid; Detect lincomycin hydrochloride in the supernatant with high performance liquid chromatography, detection result is as shown in the lincomycin hydrochloride content in the mother liquor of table 4 , the supernatant is used to recover lincomycin hydrochloride; and

[0043] (3) The solid obtained in step (2) is dried. The small test is dried in an oven at 95°C under normal pressure. In production, boiling drying ...

Embodiment 3

[0057] The processing method of the butanol crystallization mother liquor of lincomycin hydrochloride, the processing method comprises:

[0058] (1) Add 800ml of saturated sodium phosphate to 20,000ml of lincomycin hydrochloride butanol crystallization mother liquor, then add 15,000ml of water, then adjust the pH value to 7.5 with sodium hydroxide; stir well, and let stand for 1 hour Layered to obtain supernatant and lower turbidity, and then separated;

[0059] (2) The turbid liquid of above-mentioned separation is carried out centrifugation, obtains liquid and solid; Detect lincomycin hydrochloride in the supernatant with high performance liquid chromatography, detection result is as shown in the content of lincomycin hydrochloride in the mother liquor of table 7 , the supernatant is used to recover lincomycin hydrochloride; and

[0060] (3) The solid obtained in step (2) is dried. The small test is dried in an oven at 95°C under normal pressure. In production, boiling dryi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com