A fast-charging corrosion-resistant coating

A corrosion-resistant and coating technology, which is applied in the field of fast-charging corrosion-resistant coatings, can solve problems such as large expansion space, low overall strength, and shedding, and achieve the effects of improving impact resistance, improving corrosion resistance, and avoiding poor stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

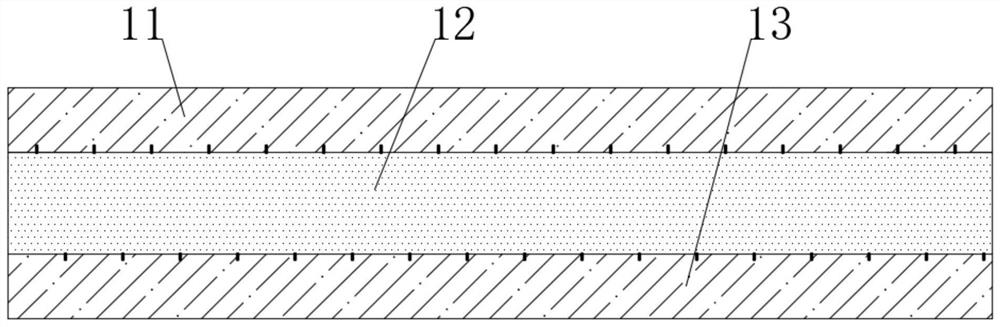

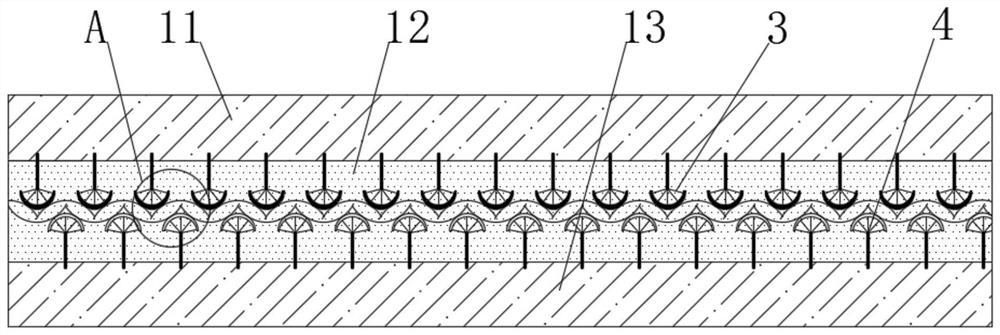

[0049] see Figure 1-2 , a fast-filling corrosion-resistant coating, including an outer coating 11 and an inner coating 13, a reinforcing interlayer 12 is connected between the outer coating 11 and the inner coating 13, and the outer coating 11, the reinforcing interlayer 12 and the inner coating 13 are sequentially arranged from outside to inside The reinforcement interlayer 12 is inlaid with two relative dislocation undulating stays, and the multiple depressions of the dislocation undulating stays near the outer coating 11 are provided with stabilizing umbrella points 3, and the dislocation undulating stays near the inner coating 13 Reinforcing umbrella points 4 are provided in multiple depressions.

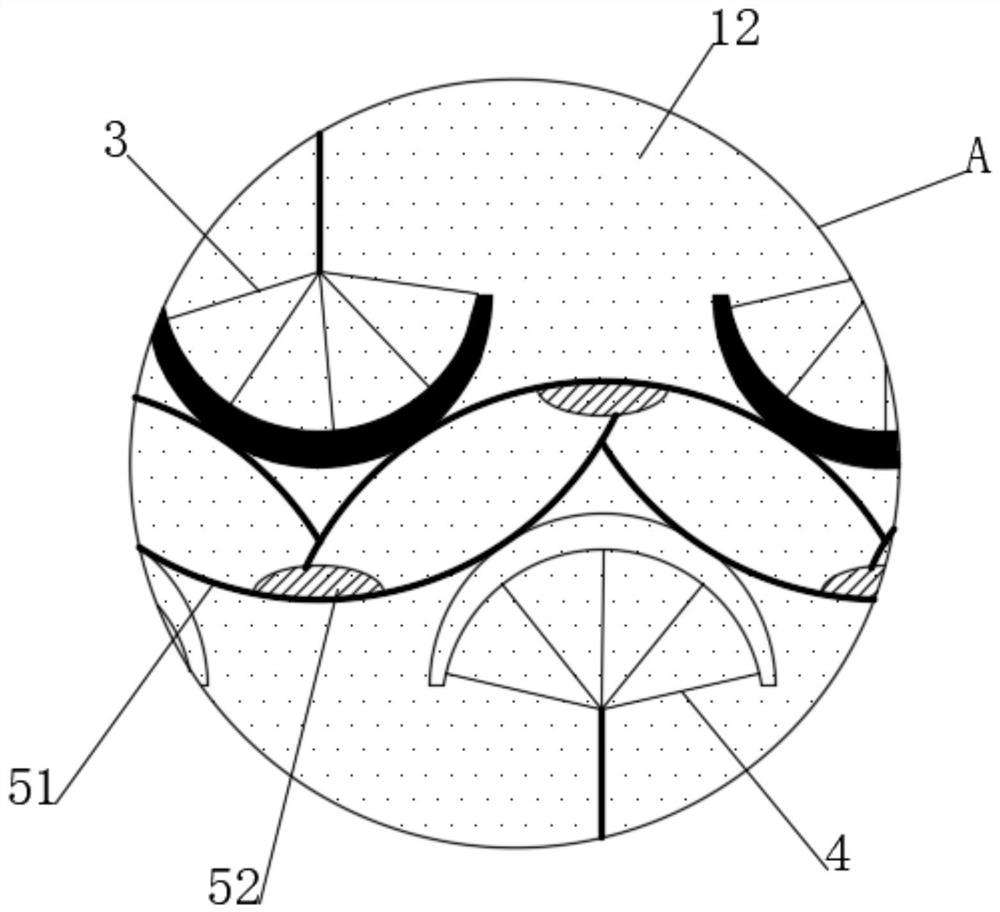

[0050] see image 3 , the undulating dislocation stay includes a plurality of arcuate skeleton pieces 51 connected end to end, the connection of the arcuate skeleton piece 51 on one dislocation undulation stay is towards the middle of the arcuate skeleton piece 51 on the other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com