Asphalt pavement heating milling machine

A technology of asphalt pavement and milling machine, which is applied in the direction of roads, roads, road repairs, etc., and can solve the problems of heating and milling machines that cannot meet the requirements of safe maintenance of asphalt pavement, high-standard and high-quality maintenance, environmental pollution, and low paving temperature and other issues, to achieve the effect of good information exchange between train groups, lower operating environment temperature, and high-standard and high-quality regeneration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

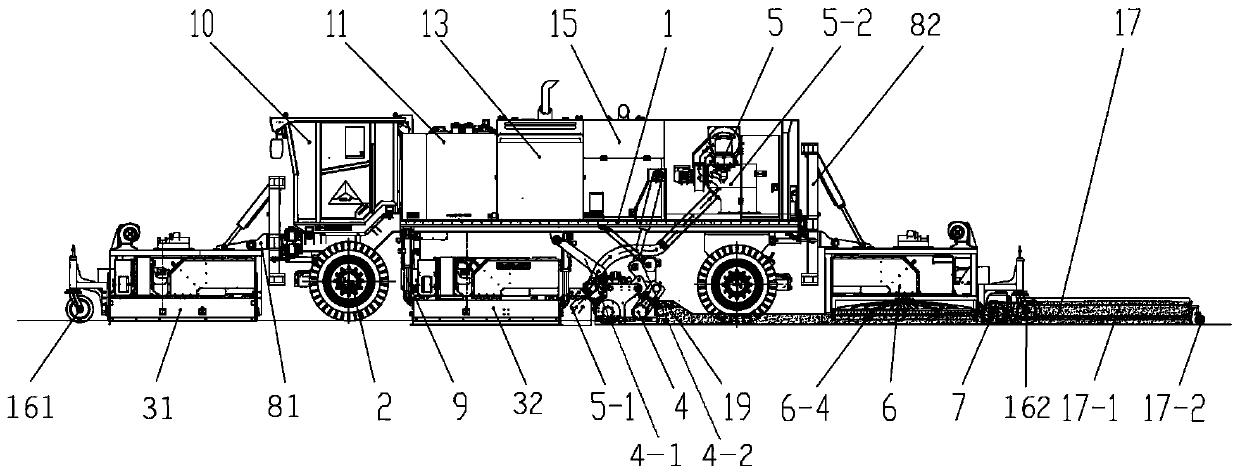

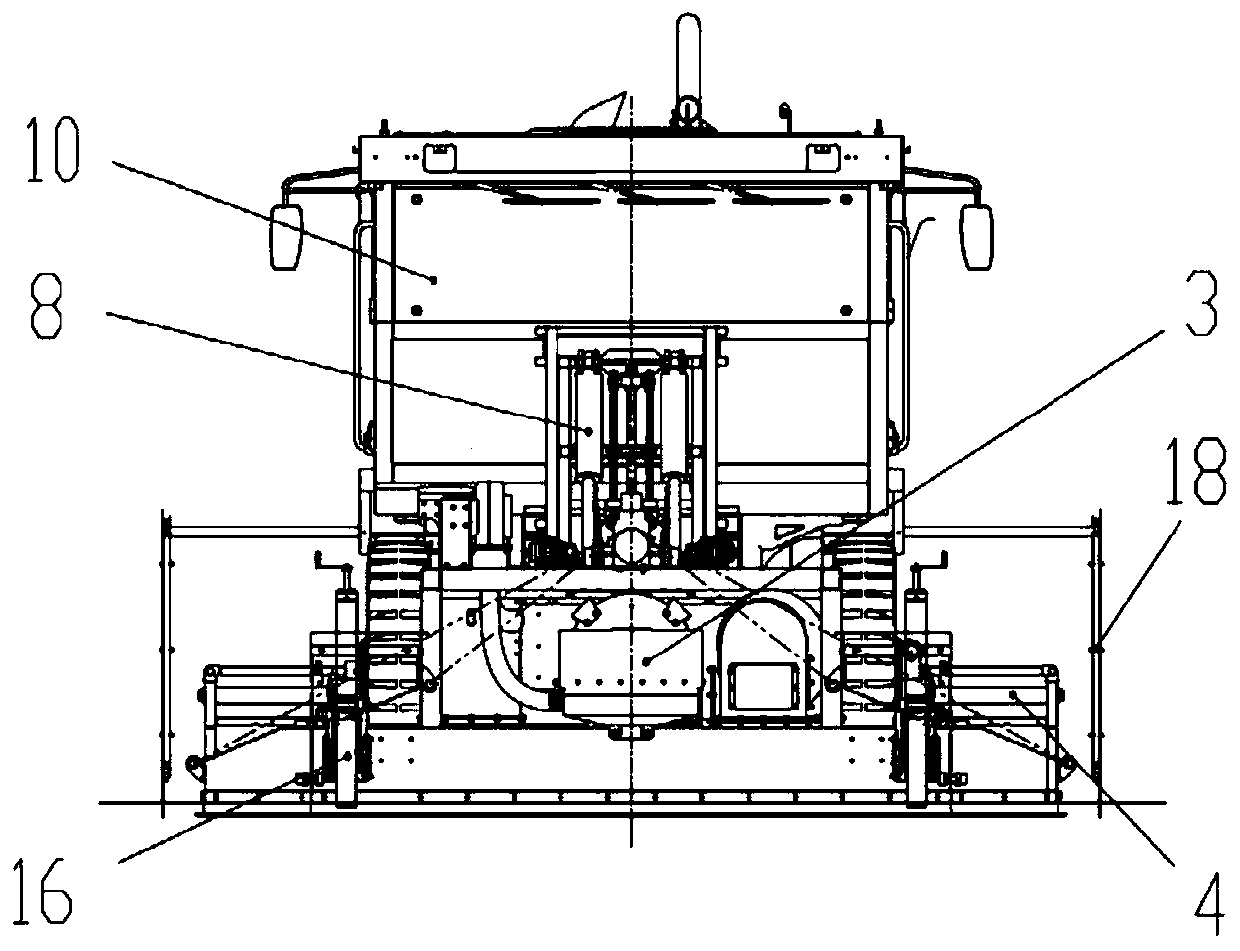

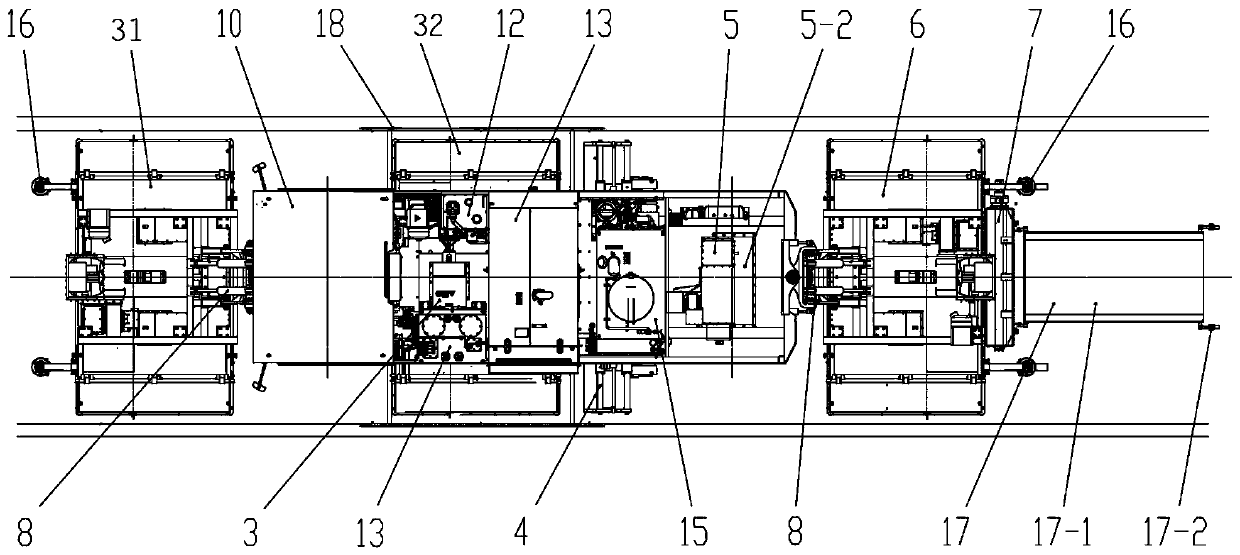

[0033] Such as Figure 1 to Figure 9 As described above, an asphalt pavement heating milling machine of the present invention includes a frame 1, a walking system 2, a first road surface heating wall 31, a second road surface heating wall 32, a milling device 4, and a secondary heating wall 6 ,

[0034] The lower part of the frame 1 fixes the walking system 2,

[0035] The walking system 2 includes a front axle and a rear axle. The first road heating wall 31 is hinged at the front end of the frame 1, the second road heating wall 32 is fixed at the rear of the front axle, and the milling device 4 is fixed on the second road heating wall 32 and Between the rear axles; the milling device 4 is located before the rear axle of the traveling system 2, and is suspended below the frame 1 through the lifting cylinder 4-1 and several groups of connecting rods 4-2. The cylinder end of the lifting cylinder 4-1 is fixed on the frame 1, the end of the piston rod is hinged to the milling de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com