Ceramic wine bottle composite inspection method

A technology of ceramic wine bottles and inspection methods, which is applied in the application of electrical devices to test fluid tightness and sorting, etc., which can solve the problem of inability to make accurate judgments on qualified products in water absorption inspections, inability to perform mass destructive inspections, and limit quality judgments Accuracy and other issues, to achieve good practical application and promotion value, low inspection cost, and improve the quality of supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

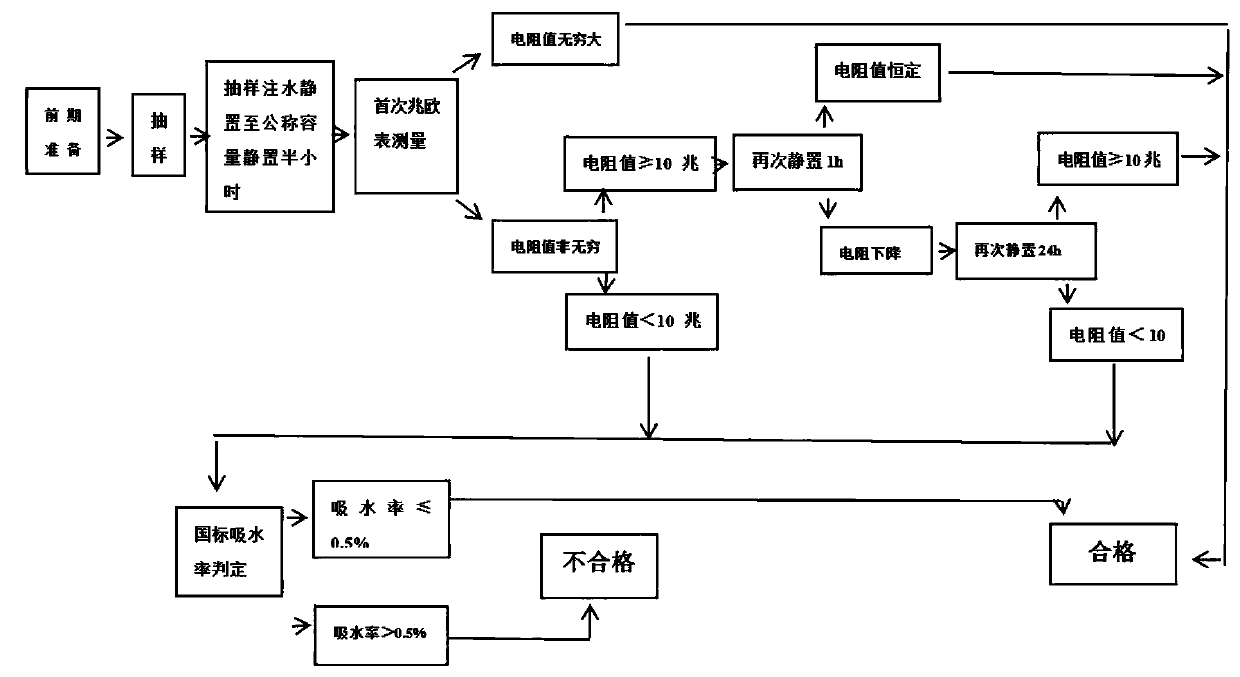

[0033] Specific embodiments of the present invention will be described in detail below.

[0034] A composite inspection method for ceramic wine bottles, taking the quality detection of the embryo body firing in the inspection of ceramic wine bottle packaging materials as an example, reasonably sampling 10 bottles (no cracks) according to the batch information of ceramic wine bottles, specifically as follows:

[0035] (1) Fill the ceramic bottle to be tested with purified water of nominal capacity and let it stand for half an hour. Note that the mouth of the bottle is wiped clean and dry with a clean rag; the water filled reaches the nominal capacity.

[0036] (2) Prepare an insulated water container, place the ceramic wine bottle to be tested in it; add pure water into the container, and the water level covers 2 / 3 of the height of the ceramic bottle.

[0037] (3) Insert the two test poles of the ohmmeter into the water in the ceramic bottle that has been left to stand for hal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com