Small-diameter conduit weld joint flexible X-ray digital detection system

A detection system and X-ray technology are applied in the field of inspection devices for the internal quality of conduit welds, which can solve problems such as the large influence of the test result skill level, the cumbersome X-ray film process flow, and the increased inspection time of conduit welds, etc., so as to achieve traceability. The effect of improving the performance, shortening the inspection cycle, and improving the digital level of the factory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, and the present invention includes but not limited to the following embodiments.

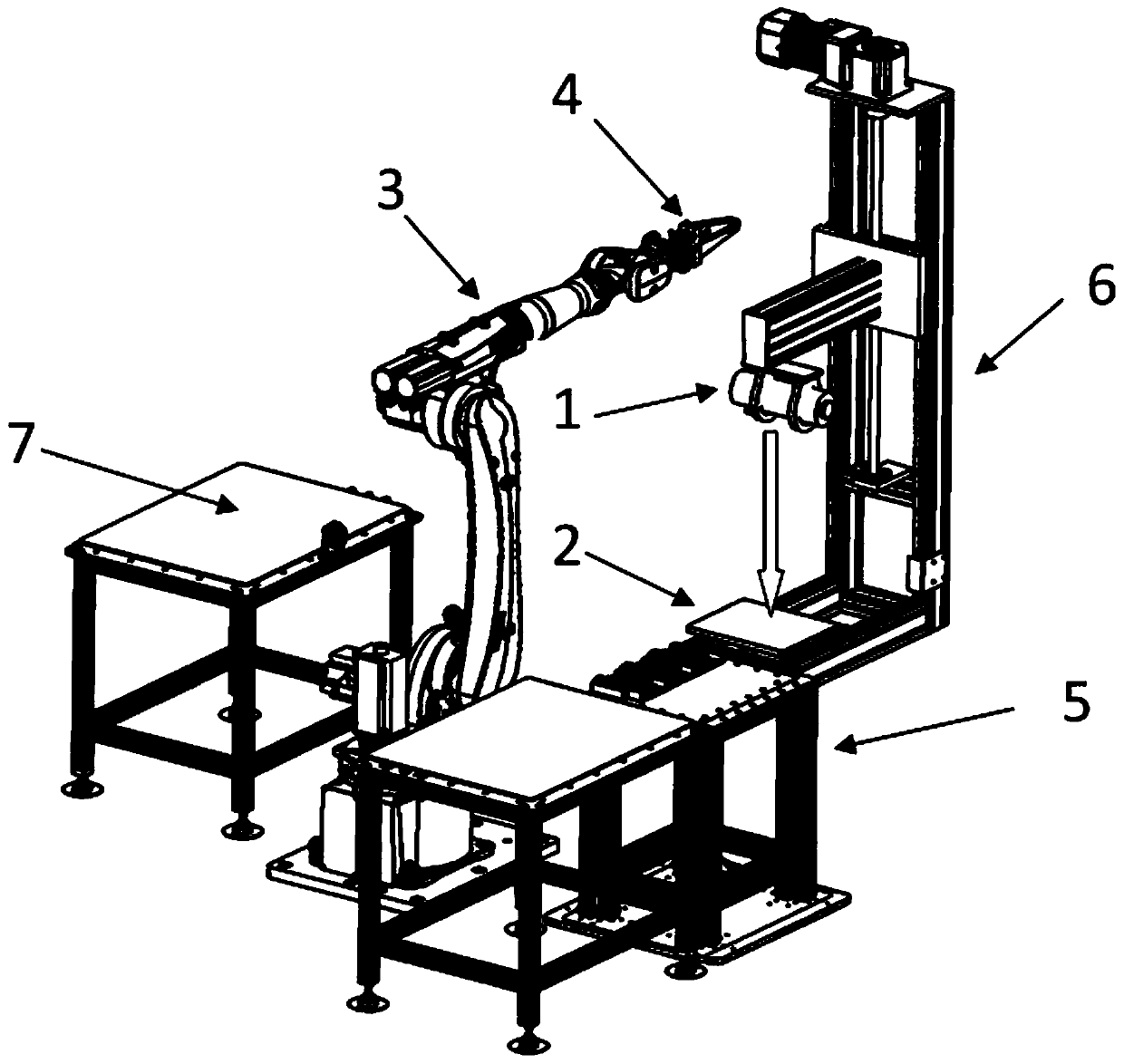

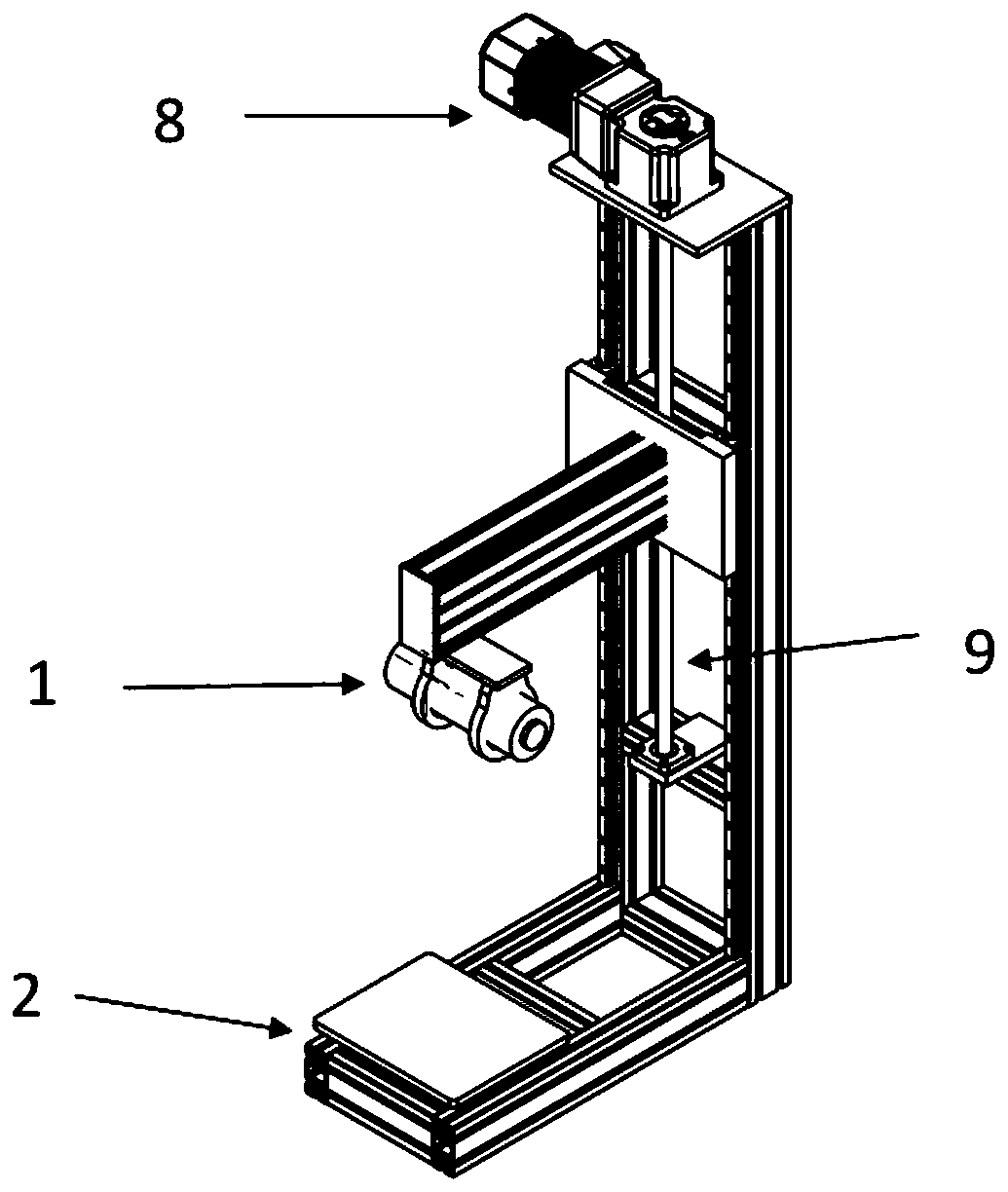

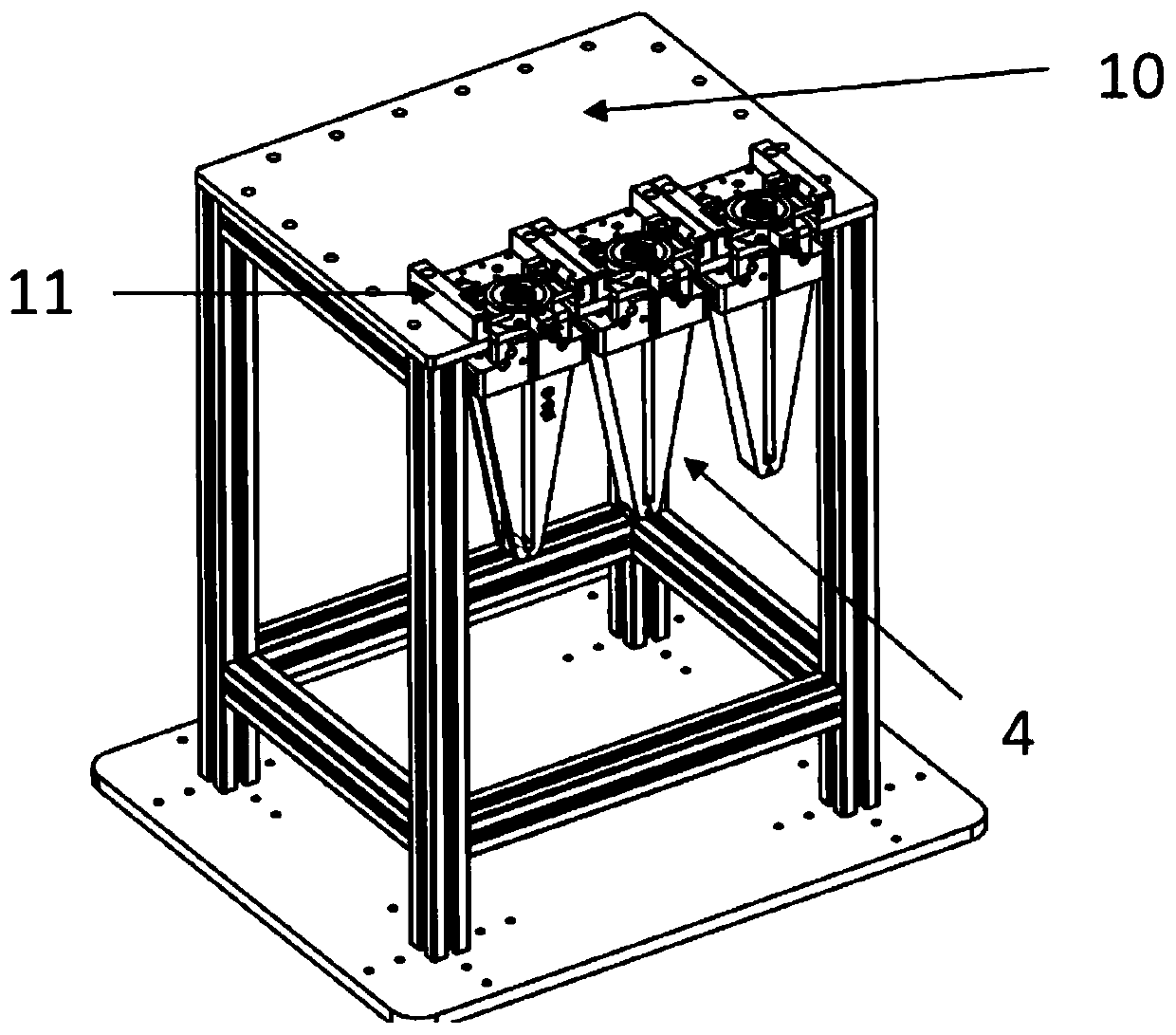

[0021] In order to solve the deficiencies of the existing small-diameter catheter weld seam detection, such as low efficiency, poor consistency, and harm to the human body, a system for changing the existing catheter weld seam detection mode is developed, including: X-ray flaw detector 1, Digital detector 2, robot 3, grasping jig 4, jig quick change station 5, focal length adjustment mechanism 6, tray 7, the material can be stainless steel, titanium, pipe diameter Inspection of more than 500 kinds of conduit welds with length less than 800mm.

[0022] The X-ray flaw detector, digital detector and robot are at least located in the lead room.

[0023] The inspector puts the catheter to be inspected on the tray 7 of the upper and lower material levels, and after entering the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com