Intelligent full-automatic aquaculture material-feeding device and material feeding method thereof

A technology for aquaculture and feeding devices, applied in the direction of outboard propulsion devices, propulsion device engines, chemical instruments and methods, etc., can solve the problems of water quality reduction, reunion, etc., and achieve the effect of avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

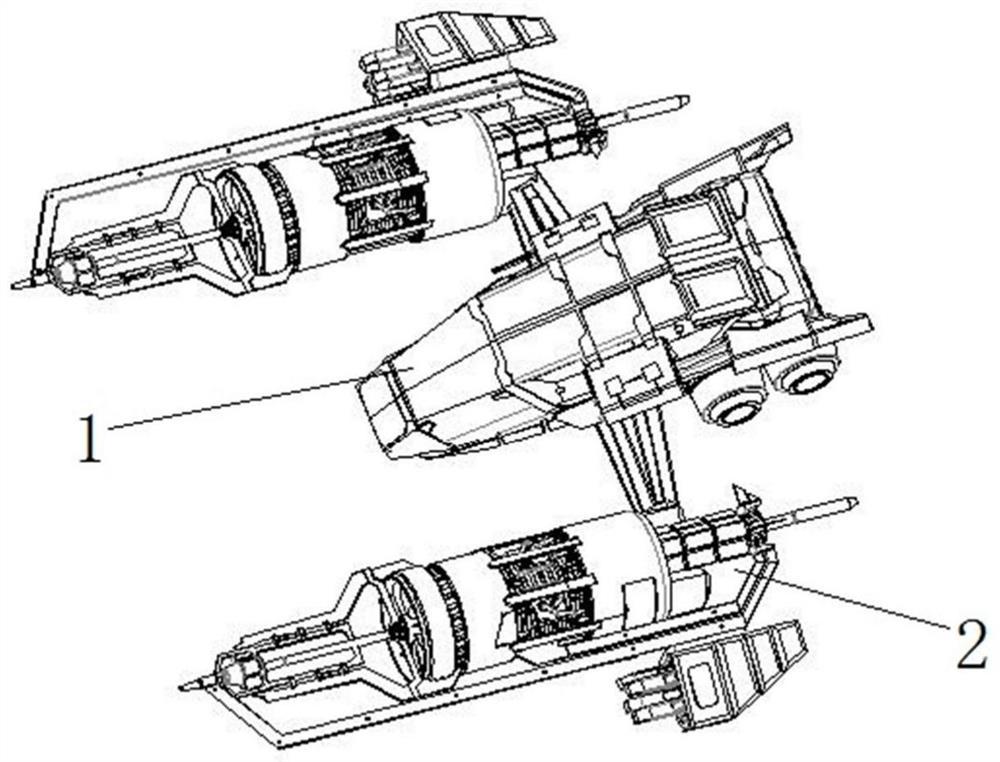

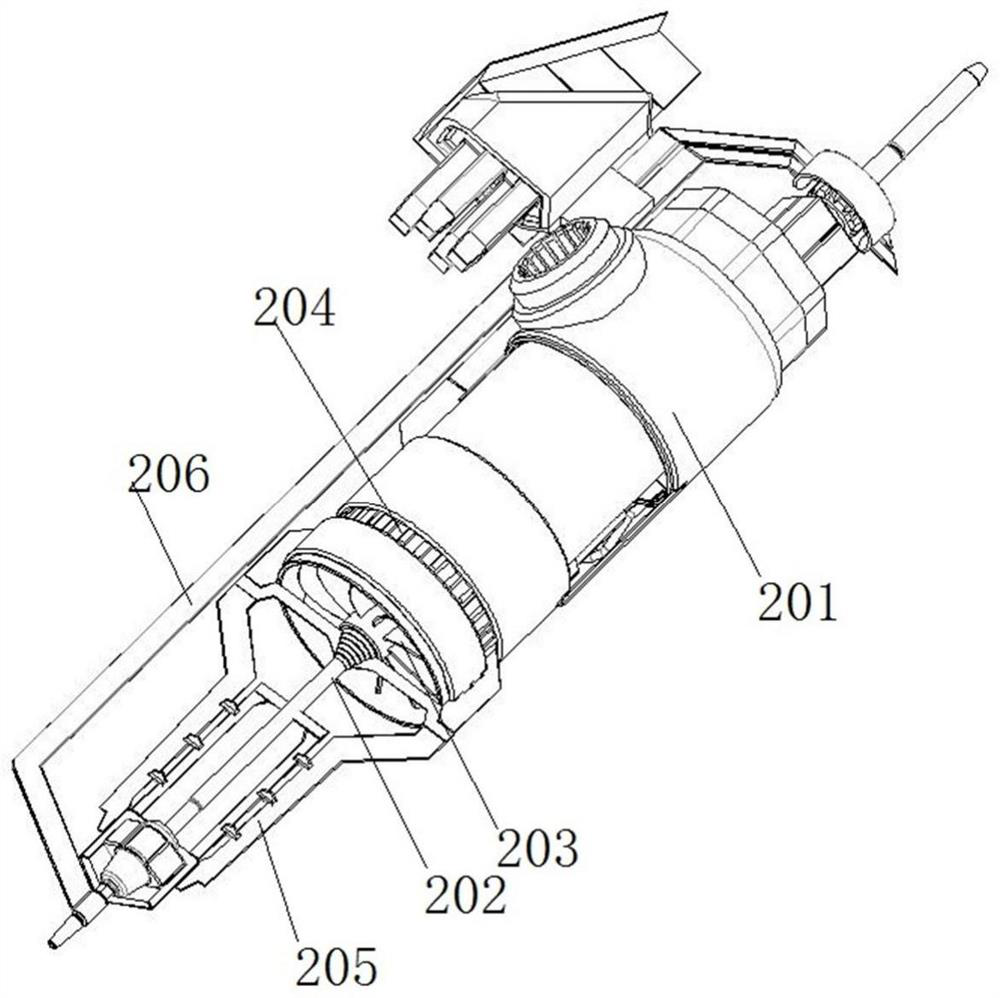

[0043] Such as figure 1 As shown, power propellers 2 are installed symmetrically on both sides of the hull 1 . Specifically, the structure of the power propeller 2 is as follows figure 2As shown, it includes: a cylindrical casing 201, the inside of which is a hollow structure. It also includes: a first rotating electrical machine with power, the first rotating electrical machine is fixed on the cylindrical housing 201, the output shaft of the first rotating electrical machine is connected with a rotating shaft 202, and the rotating shaft 202 is located on the Rotating blades 203 are tightly installed at the end of the cylindrical shell 201 , and the rotating blades 203 rotate under the drive of the first rotating motor to generate water flow and air flow, and play a role in pushing the hull 1 .

[0044] In order to solve the problem that water tanks are easy to breed at the corners of the pond mentioned above, which will cause the pontoon to be entangled, a cleaning assembl...

Embodiment 2

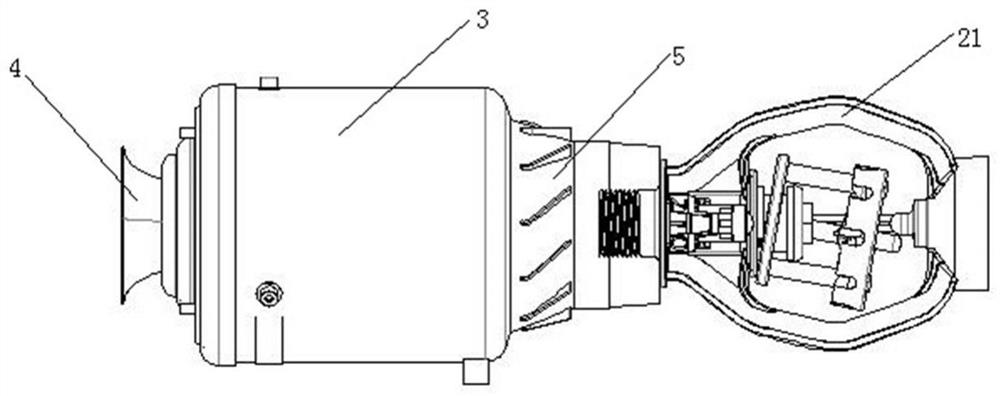

[0053] In the above-mentioned embodiment 1, the material with larger particles separated by the platform separation ring 16 still stays in the cavity 3 and needs to be effectively dissolved and dispersed by itself before entering the platform separation ring 16 for spraying. This process is slow, so the inventor made further improvements to the mixed flow assembly in order to speed up the dissolution.

[0054] Such as Figure 7 As shown, the mixed flow assembly further includes: the inside of the return cavity 5 is provided with a vane disc 18, the inner wall of the vane disc 18 is fixedly connected with the bottom of the transmission rod, and the spacer ring 16 of the table body A spring ring 15 is sleeved therein, and the spring ring 15 shakes in combination with the air flow and the liquid flow in the cavity 3 under the rotation of the blade disk 18 . In order to control the material can only flow through the discharge port from the inside of the table body partition ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com