General assembly process of 40,000-ton ore sand ship broadside block

A broadside and general section technology, applied in the direction of ships, etc., can solve the problems of difficulty in the layout of the general group tires, and achieve the effects of shortening the production cycle, improving production efficiency, and reducing manpower.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing.

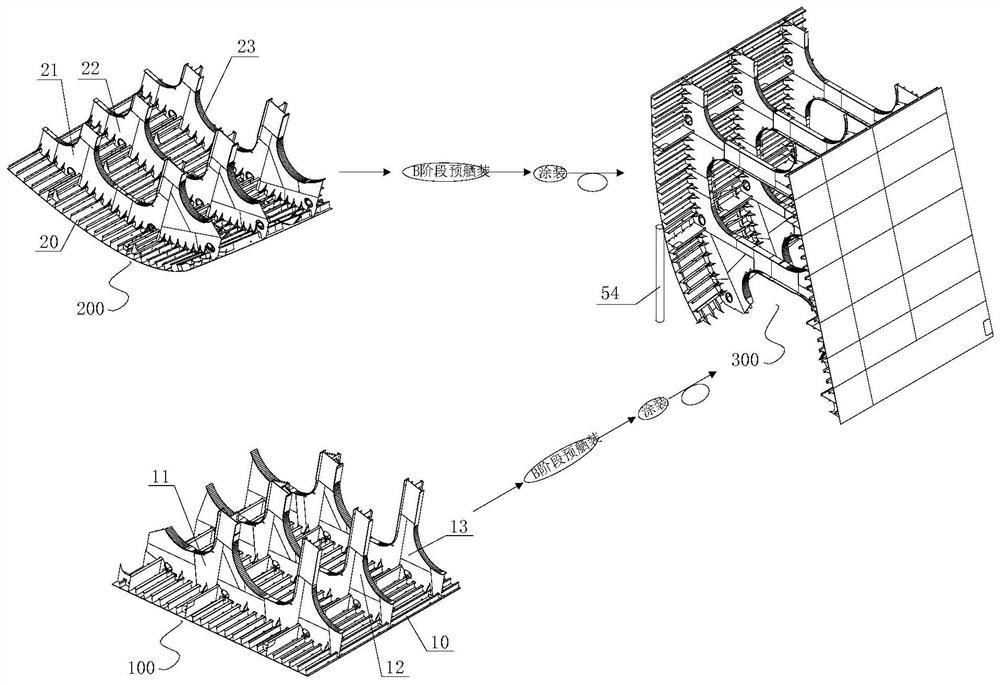

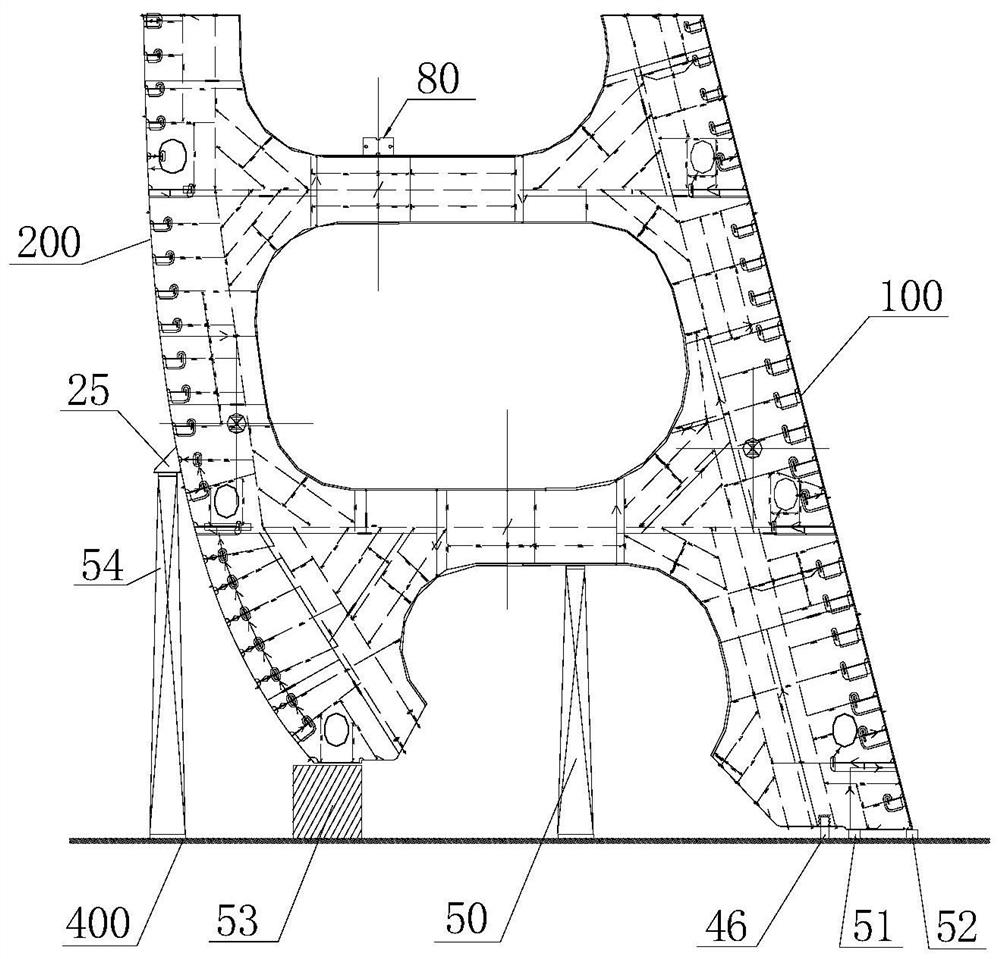

[0026] see first Figure 1 to Figure 5 , the general assembly process of the 400,000-ton ore ship's side section of the present invention, the side section 300 involved is composed of a longitudinal bulkhead segment 100 and an outboard side segment 200; wherein, the longitudinal bulkhead segment 100 has 67 No. 11, No. 69 rib 12, No. 71 rib 13 and bulkhead plate 10;

[0027] The general assembly process of the 400,000-ton ore ship side general section of the present invention is carried out on the general assembly platform and includes the following stages:

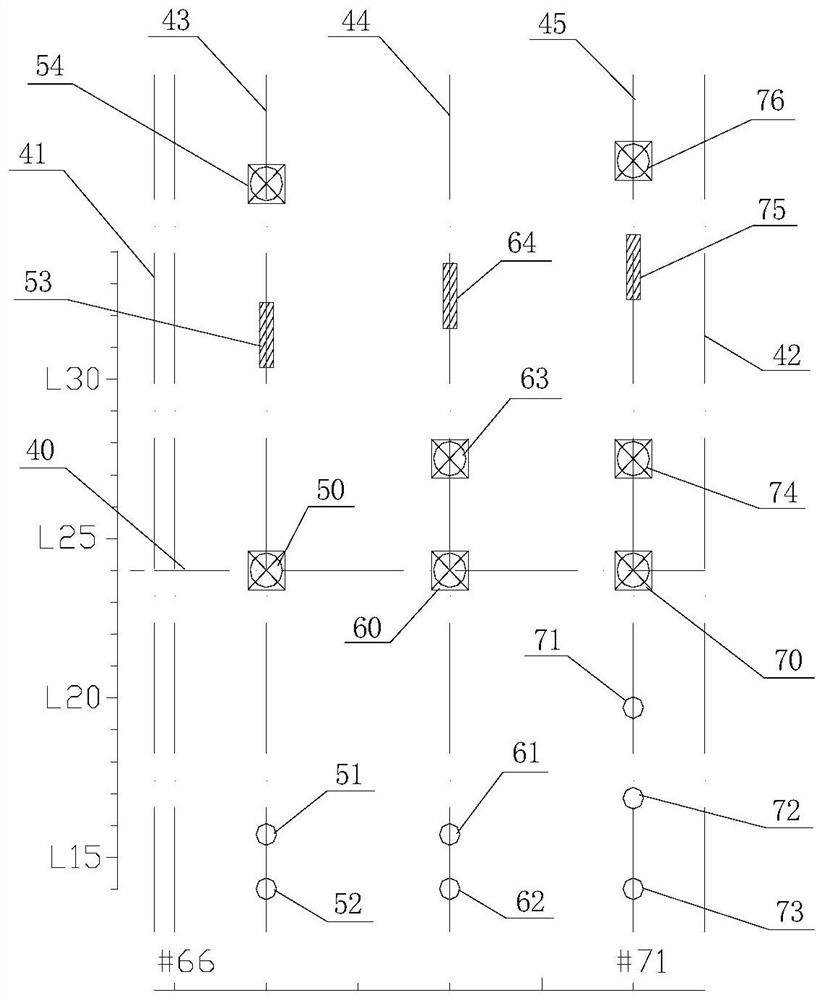

[0028]Stage 1: draw the position line of the pier on the general group platform 400, first draw the center line 40 of the general side section and the seam lines 41, 42 of the general side section on the general group platform 400, and then draw the side line The distance between No. 67 rib line 43, No. 69 rib line 44...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com