Impact-resistant conveying belt

A technology of conveyor belt and covering layer, applied in the field of conveyor belt, can solve the problems of insufficient elasticity of the belt, weak ability to absorb kinetic energy, warp breakage, etc. The effect of weft elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions and beneficial effects of the present invention will be described in detail below in conjunction with the accompanying drawings.

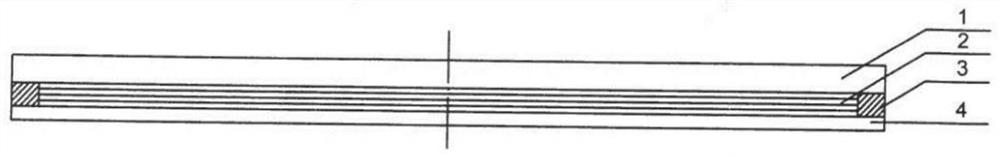

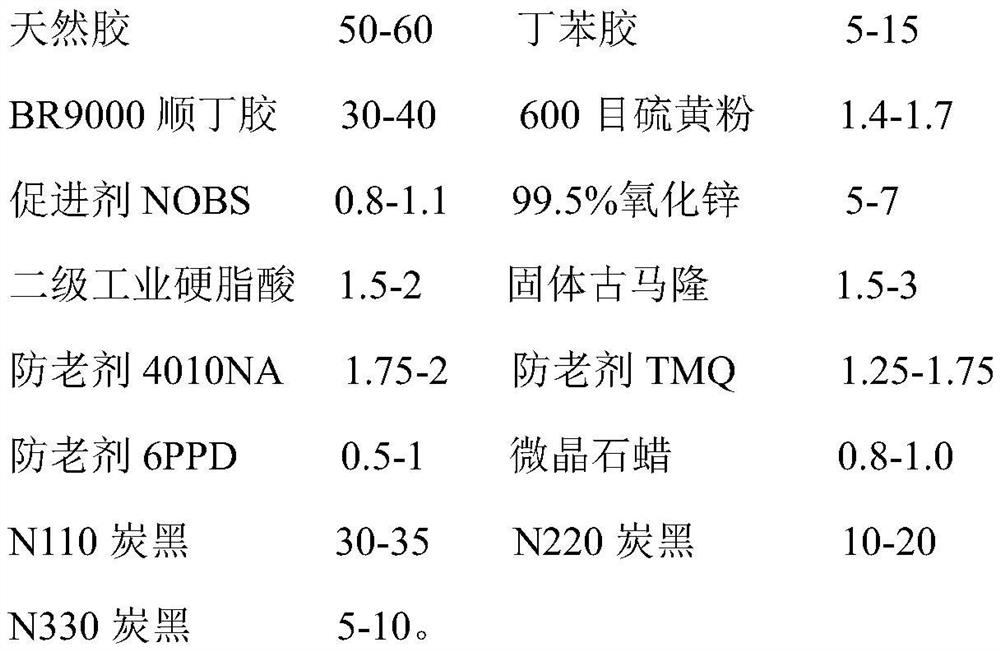

[0029] Such as figure 1 As shown, the present invention provides a crush-resistant conveyor belt, comprising an upper cover layer 1, a lower cover layer 4, a skeleton layer 2 between the upper cover layer 1 and the lower cover layer 4, and an upper cover rubber layer 1, a skeleton layer The edge glue layer 3 at both ends of the layer 2 and the lower cover layer 4; the upper cover layer 1 and the lower cover layer 4 adopt tear strength ≥ 120N / mm, wear ≤ 80mm 3 , rebound rate ≥ 25% of rubber; the skeleton layer 2 is made of canvas, the warp twist of the canvas is 5 twists / 10cm, elongation at break ≥ 18%, crimp rate ≥ 5%, weft The directional twist is 10 twists / 10cm, the density is 75±2 strands / 10cm, the average breaking strength is ≥155N / mm, the lowest breaking strength is ≥145N / mm, and the elongation at 10% constant l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic recovery rate | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com