Glazing machine

A technology of conveyor belts and detectors, which is applied to printing machines, general parts of printing machinery, printing, etc. It can solve the problems of waste products, difficult to eliminate, and affect the economic benefits and reputation of printing companies.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with various embodiments shown in the drawings. However, these embodiments do not limit the present invention, and structural, method, or functional changes made by those skilled in the art according to these embodiments are included in the protection scope of the present invention.

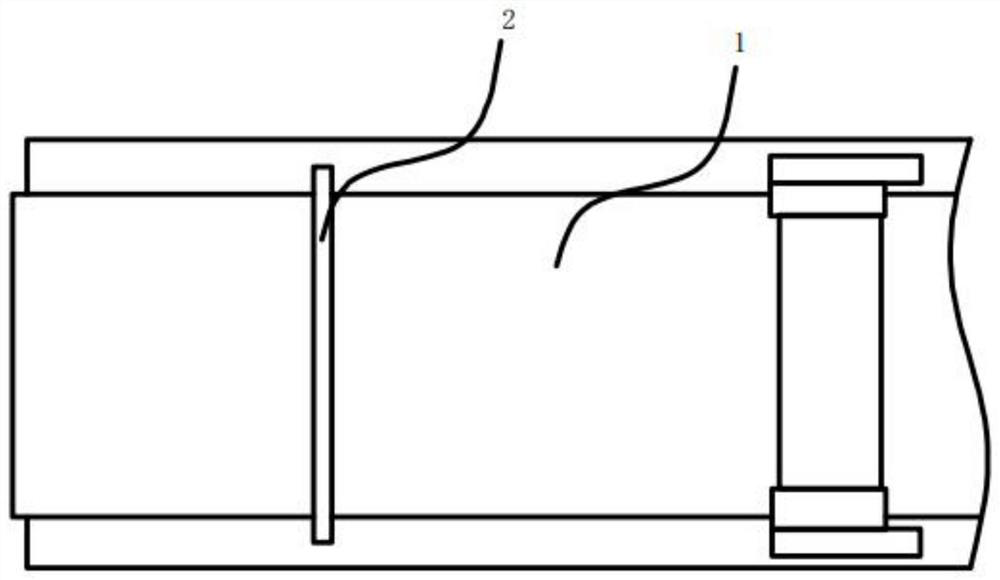

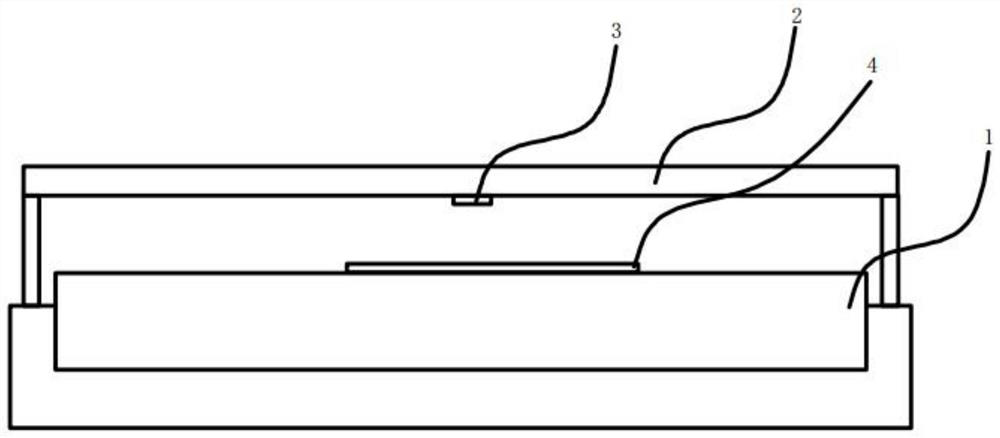

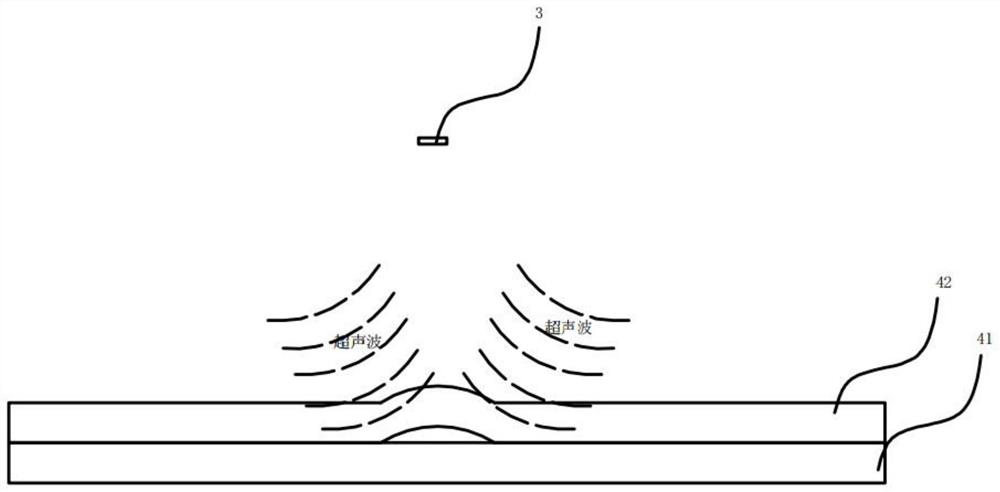

[0019] In an embodiment of the glazing machine disclosed in the present invention, it includes a conveyor belt 1 for conveying the paper product 4, and through the conveyance of the conveyor belt 1, the paper product 4 enters different processes to complete the entire glazing operation, such as Complete multiple glazing operations such as humidification, coating of powder or paint or glue to form a thin layer, gluing, curing, drying, etc. Of course, the selection of the specific process here depends on the material process, the weight of the glazing material and the paper product4 Comprehensive consideration of properti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com