Krah pipe and preparation method thereof

A carat tube and resin technology, applied in the field of carat tube and its preparation, can solve the problems of poor plasticizing effect, low HDPE peel strength, secondary rework, etc., achieve improved pressure resistance and peel performance, excellent bonding performance, Good impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

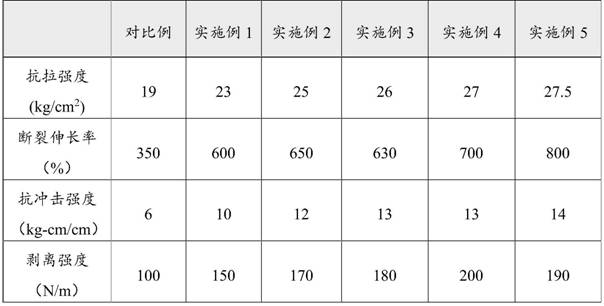

Examples

Embodiment 1

[0027] First weigh 270kg of HDPE polyethylene raw material, add 10.4kg of fatty acid glyceride into the mixer, mix for 10 minutes, then add 56.3kg of adhesive resin, 28.4kg of PP polyethylene resin, mix for 5 minutes, add 28.4kg of ABS resin and 28.4kg of CPE resin, mixed for 5 minutes, finally weighed 5.9kg of diheptyl phthalate, 4.5kg of KH550, 2.3kg of polyvinyl alcohol, 6.8kg of magnesium sulfate, 6.8kg of potassium stearate and mixed for 5 minutes, then transported Pellet in a granulator at 200°C to obtain a stable carat tube mixture; plasticize and extrude to obtain the carat tube.

Embodiment 2

[0029] First weigh 179.4kg of HDPE polyethylene raw material, add 3kg of fatty acid glyceride into the mixer, mix for 10 minutes, then add 37.5kg of adhesive resin, 24kg of PP polyethylene resin, mix for 5 minutes, add 24kg of ABS resin and CPE resin 15kg, mixed for 5 minutes, finally weighed 6kg of bis(2-ethylhexyl) phthalate, 2.4 kg of KH550, 1.2kg of polyvinyl alcohol, 3.9kg of magnesium sulfate, and 3.6kg of potassium stearate after 5 minutes of mixing , transported to a granulator and granulated at 200°C to obtain a stable carat tube mixture; plasticized and extruded to obtain the carat tube.

Embodiment 3

[0031] First weigh 200.2kg of HDPE polyethylene raw material, 3.5kg of fatty acid glyceride [Xiao] into the mixer, mix for 10 minutes, then add 35kg of adhesive resin, 38.5kg of PP polyethylene resin, mix for 5 minutes, add ABS resin 21kg and 28 kg of CPE resin, mix for 5 minutes, and finally weigh 10.5kg of dioctyl phthalate, 2.1kg of KH550, 1.1kg of polyvinyl alcohol, 5.3kg of magnesium sulfate, and 4.9kg of potassium stearate after mixing for 5 minutes , transported to a granulator and granulated at 200°C to obtain a stable carat tube mixture; plasticized and extruded to obtain the carat tube.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com