Cooling device of sodium hypochlorite generator

A cooling device, sodium hypochlorite technology, applied in the electrolysis process, electrolysis components and other directions, can solve the problems of insufficient heat dissipation, unstable sodium chlorate rate, etc., to achieve the effects of stable rate, inhibiting rate, and increasing water flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following is further described in detail through specific implementation methods:

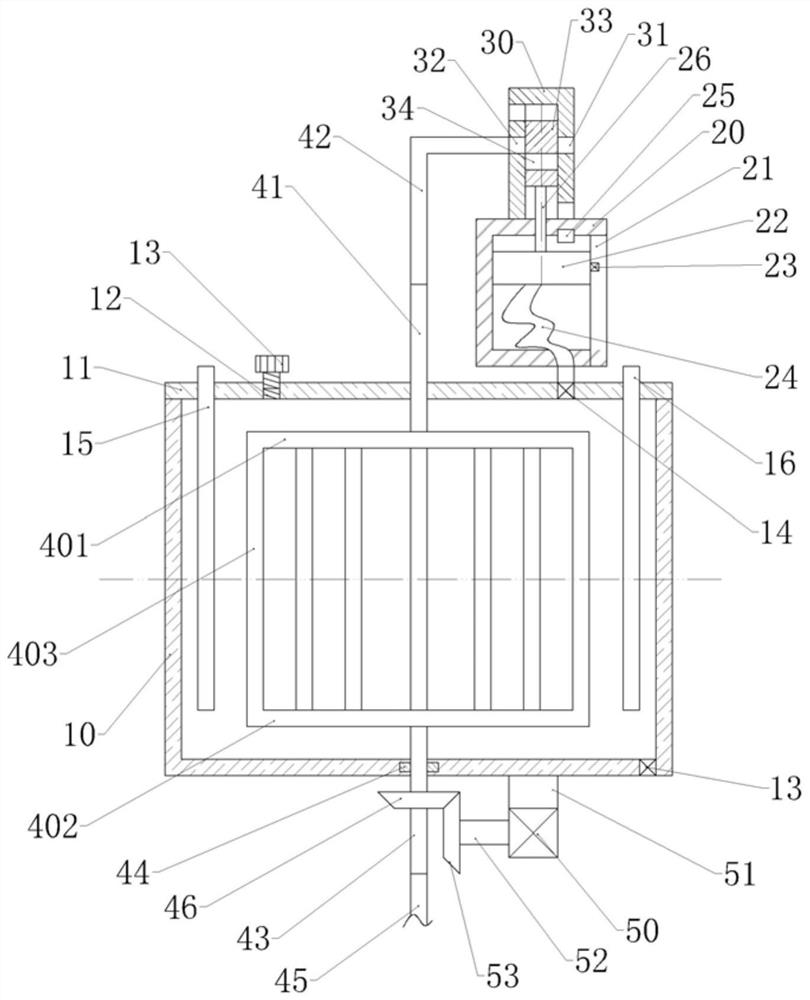

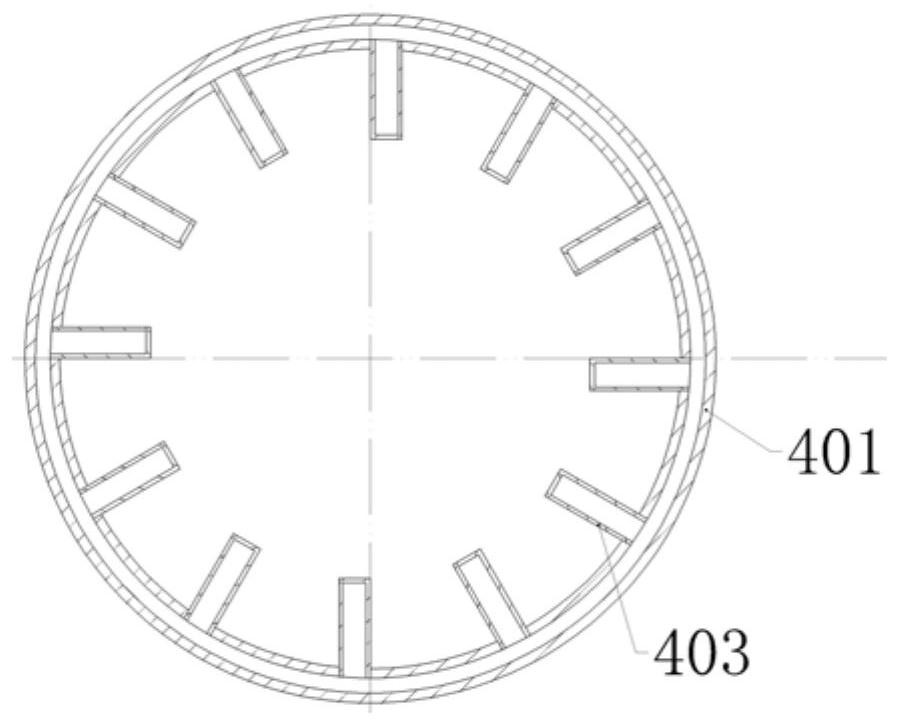

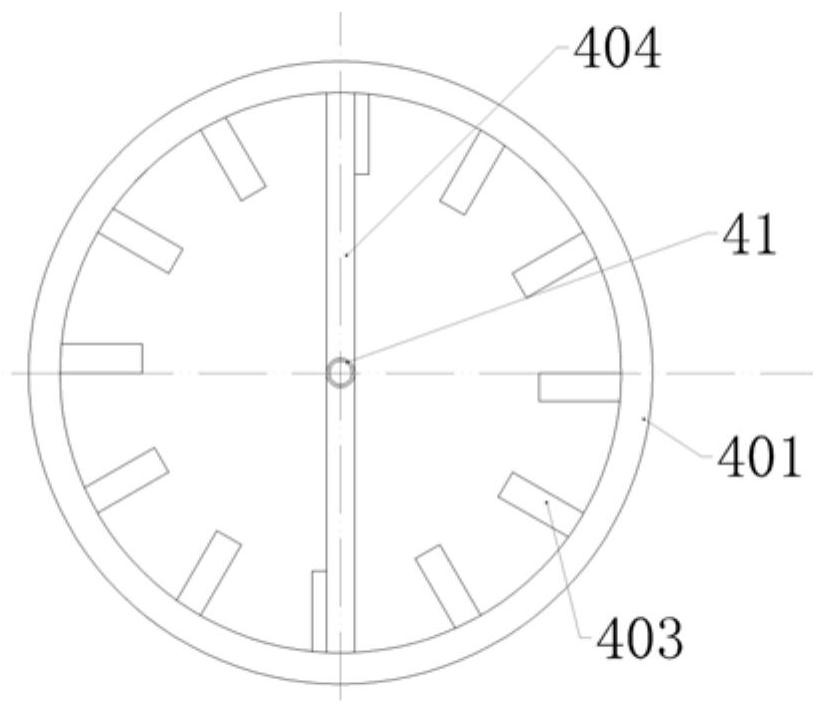

[0029] The reference signs in the accompanying drawings include: electrolytic cell 10, cover body 11, threaded through hole 12, plug 13, one-way exhaust valve 14, anode 15, cathode 16, first box body 20, strip through hole 21 , air box 22, automatic valve 23, hose 24, automatic valve switch 25, connecting rod 26, second box body 30, water inlet hole 31, water outlet hole 32, slider 33, connection hole 34, first annular pipe 401 ,, the second annular pipe 402, the intermediate connecting pipe 403, the horizontal connecting pipe 404, the upper connecting pipe 41, the water inlet pipe 42, the lower connecting pipe 43, the limit block 44, the water outlet pipe 45, the first bevel gear 46, the motor 50, A fixed plate 51 , a rotating shaft 52 , and a second bevel gear 53 .

[0030] The embodiment is basically as attached figure 1 - attached image 3 Shown: a sodium hypochlorite generato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com