Modified elastomer, thermoplastic mortar/concrete conveying pipe and manufacturing method of thermoplastic mortar/concrete conveying pipe

A concrete delivery pipe, thermoplastic technology, applied in the direction of pipes/pipe joints/fittings, hoses, pipes, etc., can solve the problems of waste of manpower, non-environmental protection, poor wear resistance, etc., to avoid the inconvenience of pipeline use, improve durability Grinding performance, the effect of good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] The preparation method of the above-mentioned modified elastomer is as follows: after uniformly mixing the raw materials in proportion, extruding and pelletizing with a twin-screw extruder, and the extruding temperature is 100-250°C.

[0065] The present invention also provides a preparation method for the above-mentioned thermoplastic mortar / concrete delivery pipe, comprising the steps of:

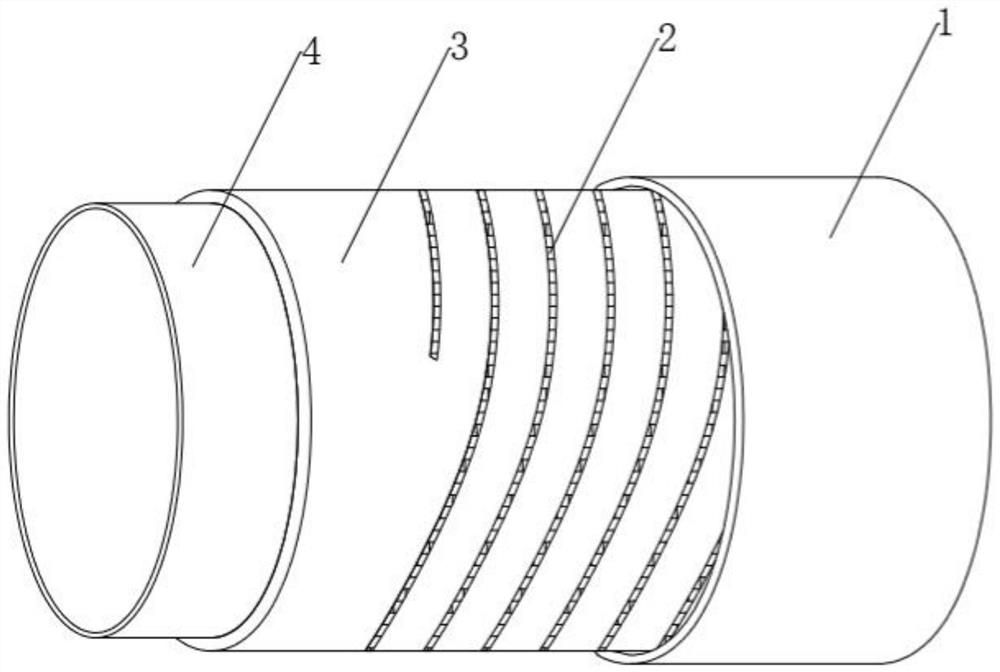

[0066] [1] A wear-resistant core tube composed of a modified elastomer layer and a wear-resistant material layer is prepared by co-extruding the modified elastomer and the inner layer of wear-resistant material. The wear-resistant material provides the wear resistance of the final product, and the modified elastic The body provides melt strength under the premise of ensuring softness to ensure product extrusion performance and product longitudinal strength;

[0067] [2] Prepare a winding layer on the periphery of the wear-resistant core tube to provide radial strength and ensure th...

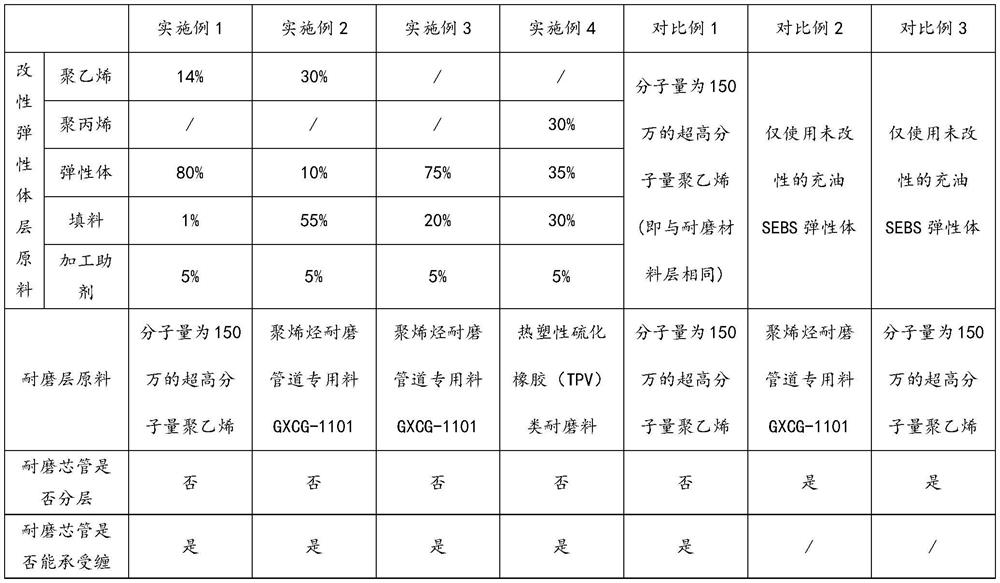

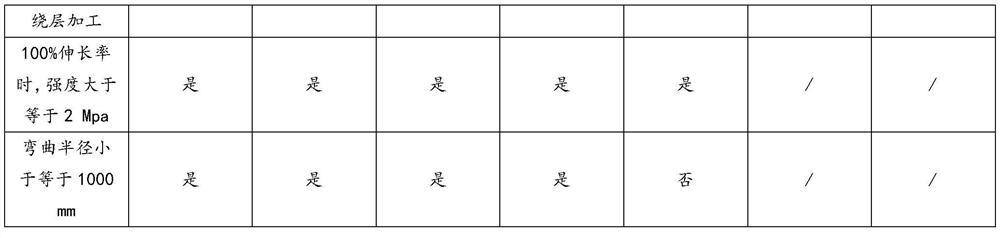

Embodiment 1

[0071] The modified elastomer used for the material of the outer sheath 1 is made of the following raw materials in mass percentage: 1% calcium carbonate filler, 80% oil-extended SEBS elastomer, 14% polyethylene, 1% hindered phenolic antioxidant, polyethylene Wax 2%, Masterbatch 2%.

[0072] The winding layer 2 selects steel wire for spiral winding.

[0073] The modified elastomer used in the modified elastomer layer 3 is made of the following raw materials in mass percentage: 1% of calcium carbonate filler, 90% of oil-extended SEBS elastomer, 4% of polyethylene, 1% of hindered phenolic antioxidant, polyethylene Wax 2%, Masterbatch 2%.

[0074] The wear-resistant material used in the wear-resistant material layer 4 is ultra-high molecular weight polyethylene with a molecular weight of 1.5 million.

Embodiment 2

[0076] The modified elastomer used for the material of the outer sheath 1 is made of the following raw materials in mass percentage: calcium carbonate filler 55%, oil-extended SEBS elastomer 10%, polyethylene 30%, hindered phenolic antioxidant 1%, polyethylene Wax 2%, Masterbatch 2%.

[0077] The winding layer 2 selects steel wire for spiral winding.

[0078] The modified elastomer used in the modified elastomer layer 3 is made of the following raw materials in mass percentage: calcium carbonate filler 55%, oil-extended SEBS elastomer 10%, polyethylene 30%, hindered phenolic antioxidant 1%, polyethylene Wax 2%, Masterbatch 2%.

[0079] The wear-resistant material used in the wear-resistant material layer 4 is GXCG-1101, a special material for polyolefin wear-resistant pipes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com