A cabling device for power cable production and a method of using the same

A power cable and cabling technology, applied in conductor/cable supply devices, cable/conductor manufacturing, circuits, etc., can solve the problems of loose winding, uneven force on cables, affecting cabling, etc., to ensure the effect of cabling , space saving, reasonable structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

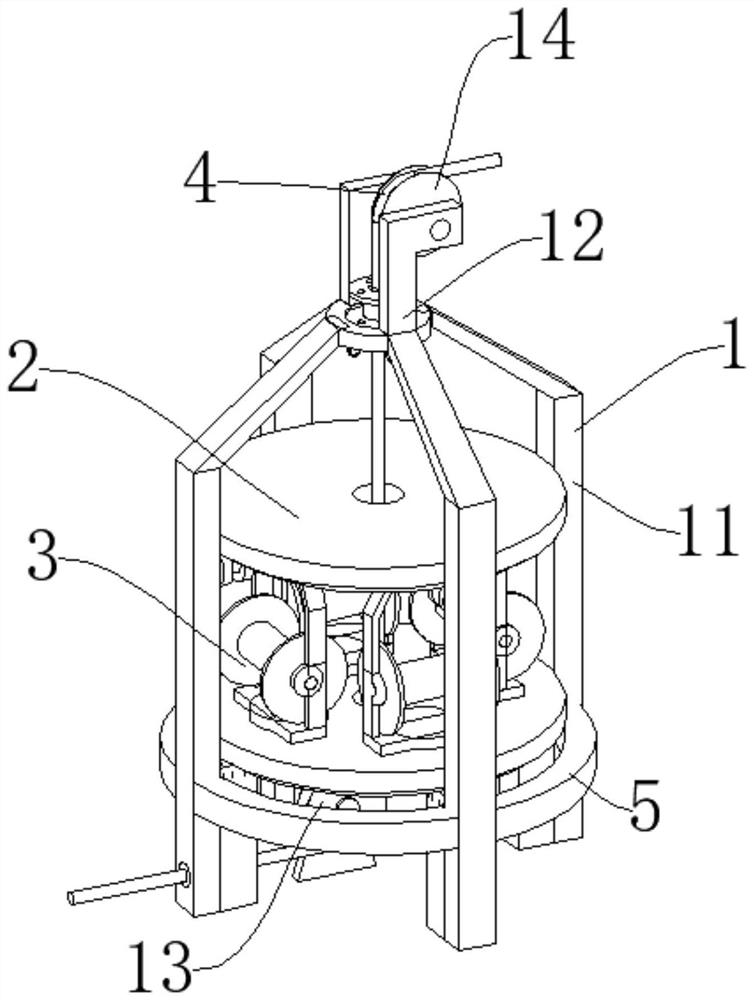

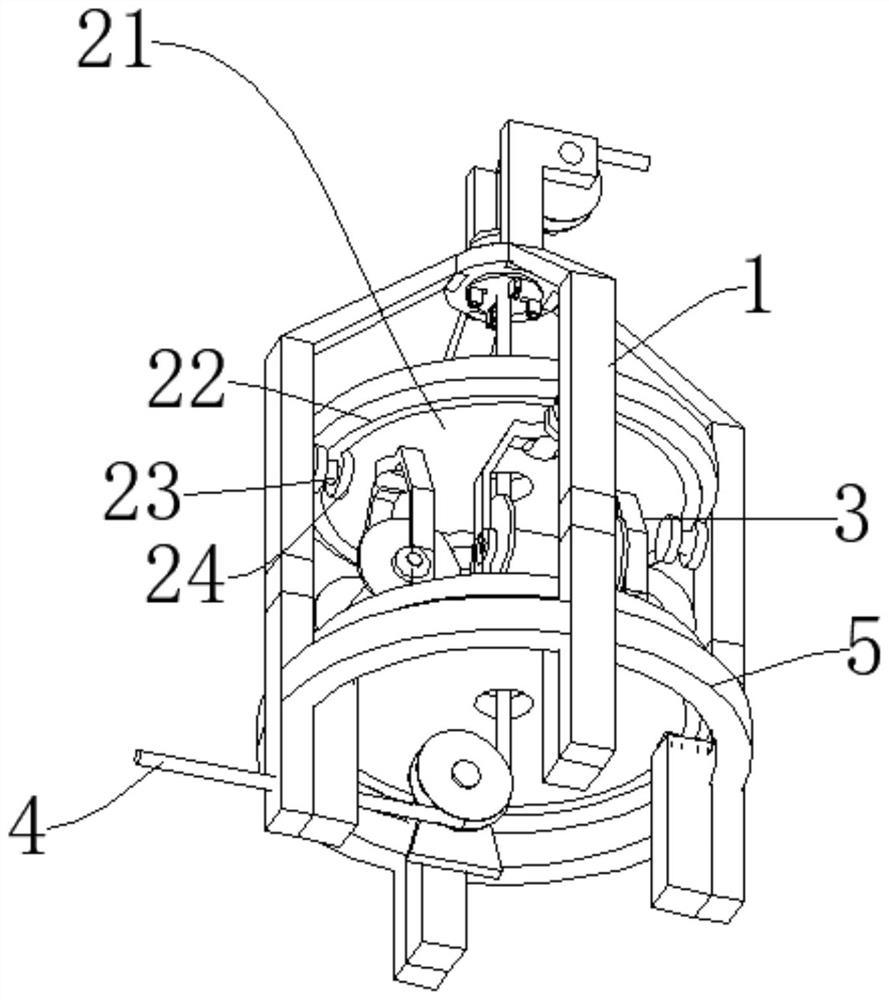

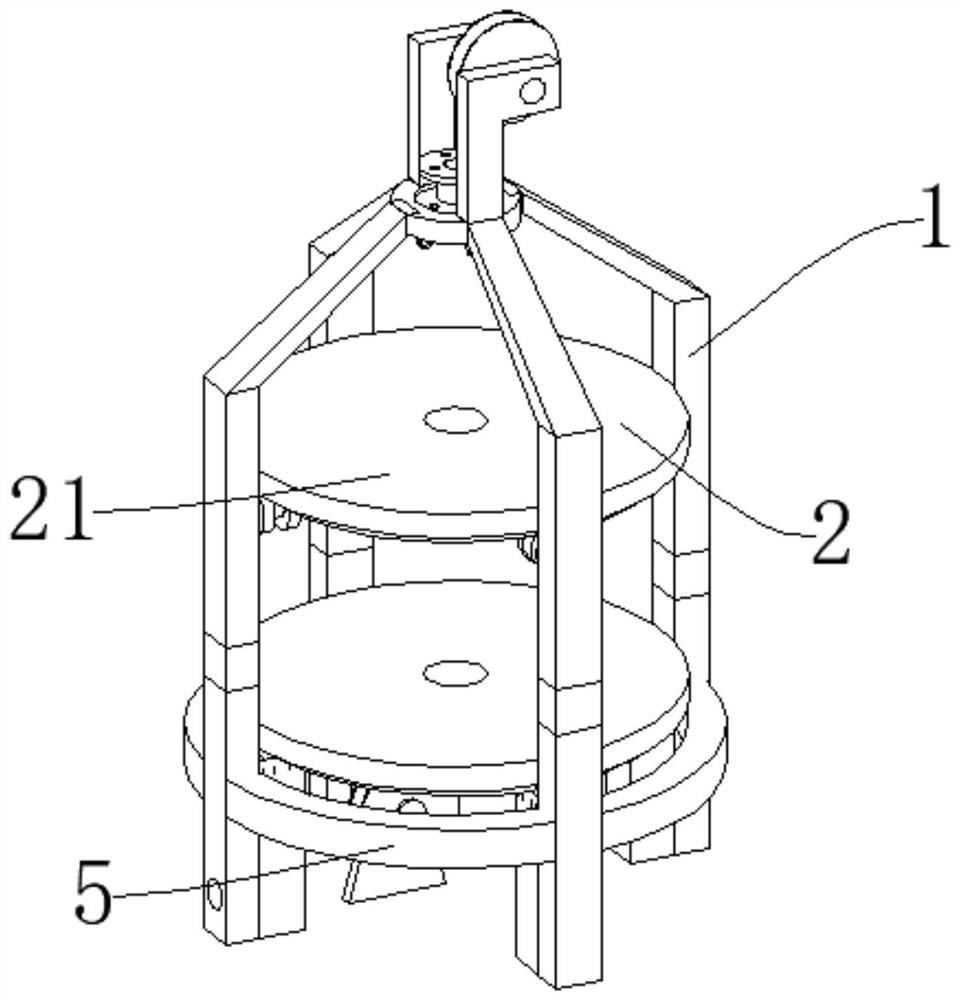

[0049] Such as Figure 1-Figure 8 , as shown, the transmission mechanism 7 includes a passive bevel gear 71, an active bevel gear 72, a transmission rod 73, and a motor 74. The passive bevel gear 71 is connected to the transmission gear 23 of the rotating mechanism 2, the active bevel gear 72 is connected to the passive bevel gear 71, and the active bevel gear 72 is connected to the passive bevel gear 71. The power end of gear 72 is connected to transmission rod 73, and the power end of transmission rod 73 is connected to motor 74. 71, so that the driven bevel gear 71 drives the transmission gear 23 to rotate, and the transmission gear 23 cooperates with the gear bar 22 at the lower end of the rotating disk 21 after rotating, thereby driving the rotating disk 21 to rotate; the supporting mechanism 1 includes a column 11, an upper wheel mounting frame 12, a lower end Guide wheel 13, upper end guide wheel 14, column 11 upper end connects upper wheel installation frame 12, connec...

Embodiment 2

[0052] Such as Figure 9 The difference between this embodiment and Embodiment 1 is that the transmission mechanism 7 includes a worm wheel 711, a worm 712, and a motor 74, and the motor 74 is connected to the inside of the column 11 of the support mechanism 1, and the output end of the motor 74 is connected to the worm 712, and the worm 712 is connected to two The worm gear 711, the output end of the worm gear 711 is connected to the transmission gear 23 of the rotating mechanism 2, the motor 74 drives the worm 712 to rotate, the worm 712 meshes with the worm gear 711, thereby driving the transmission gear 23 to rotate, after the transmission gear 23 rotates, it cooperates with the gear bar at the lower end of the rotating disk 21 22, thereby driving the rotating disc 21 to rotate.

[0053] A method for using a cabling device for power cable production, characterized in that it includes the following steps:

[0054] a. Pass the cable 4 through the lower guide wheel 13, the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com