Cloud control system and method for loading and unloading process of automatic-driving mine truck

A technology for autonomous driving and mining vehicles. It is used in transmission systems, communications between vehicles and infrastructure, and vehicle components. It can solve problems such as difficult to control uniform loading, soft and uneven ground, and large differences in density. Reliable, low-cost, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

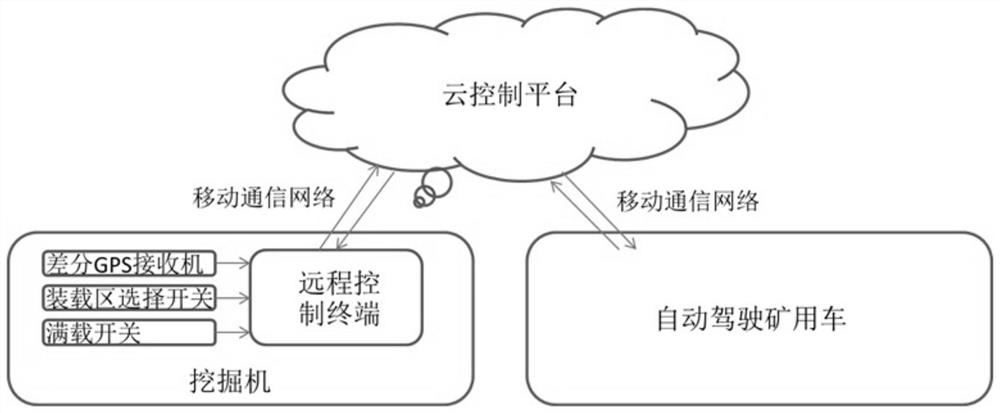

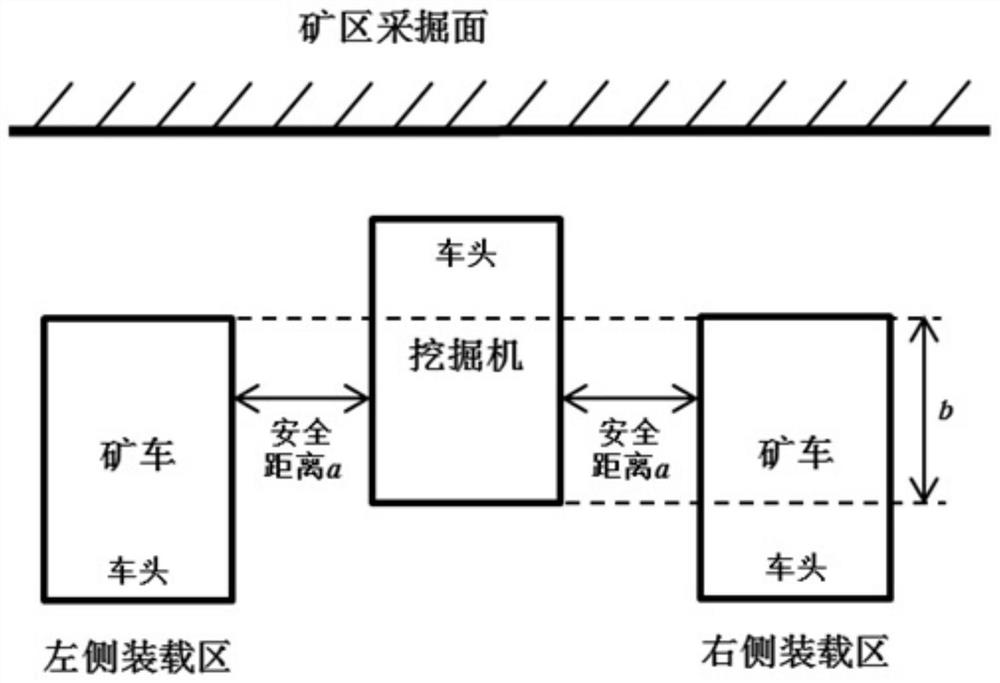

[0028] According to the current mining area, there are only self-driving mining vehicles, and there is no automatic excavator or automatic loading system. It is still the characteristic that the driver drives the excavator to complete the loading of materials. The cloud control platform determines several safe loading areas around the excavator based on the position of the excavator, the direction of the head of the car and the digital map, and the driver of the excavator selects which loading area the mine car is loaded in, and judges whether it is full. The information is reported to the The cloud control platform controls the mine car to complete the parking and loading process.

[0029]A differential GPS receiver and a remote control terminal are installed on the excavator, and a loading area selection switch and a full-load switch are set on the operator panel of the cab for the driver to select and operate. The remote control terminal uploads the real-time location infor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com