Device for separating solar cell module glass

A solar cell module and glass technology, applied in transportation and packaging, solid waste removal, chemical instruments and methods, etc., can solve the problems of high residual glue rate on the glass surface, difficulty in obtaining complete glass, etc., to ensure integrity and efficiency , reduce the amount of residual film, and ensure the integrity of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

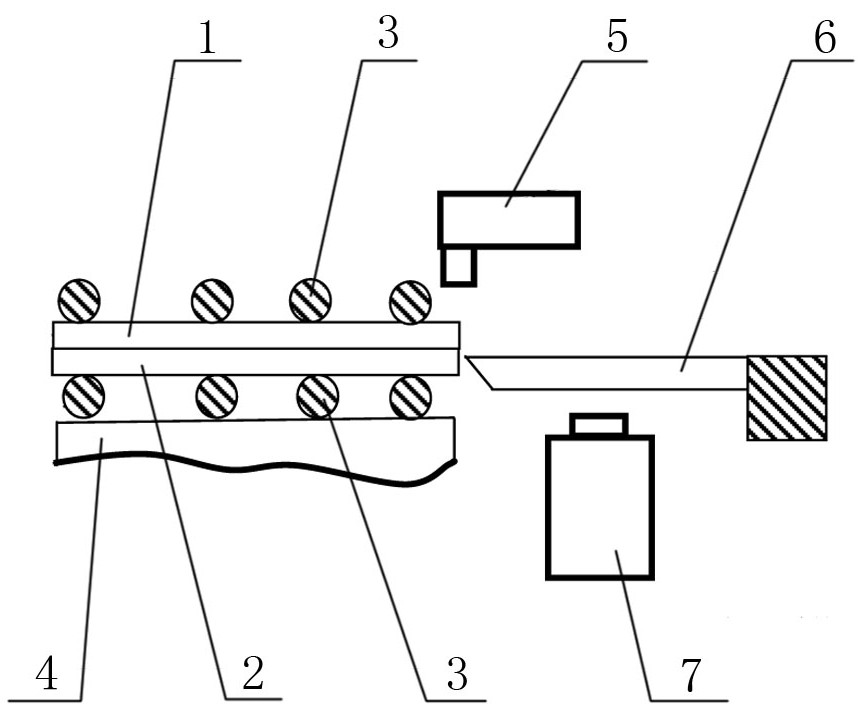

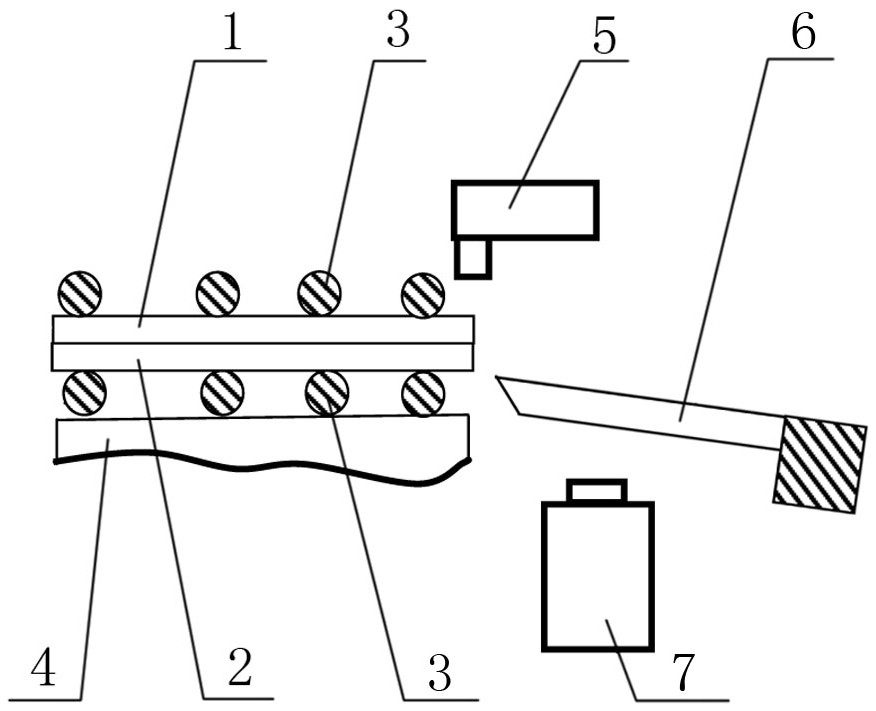

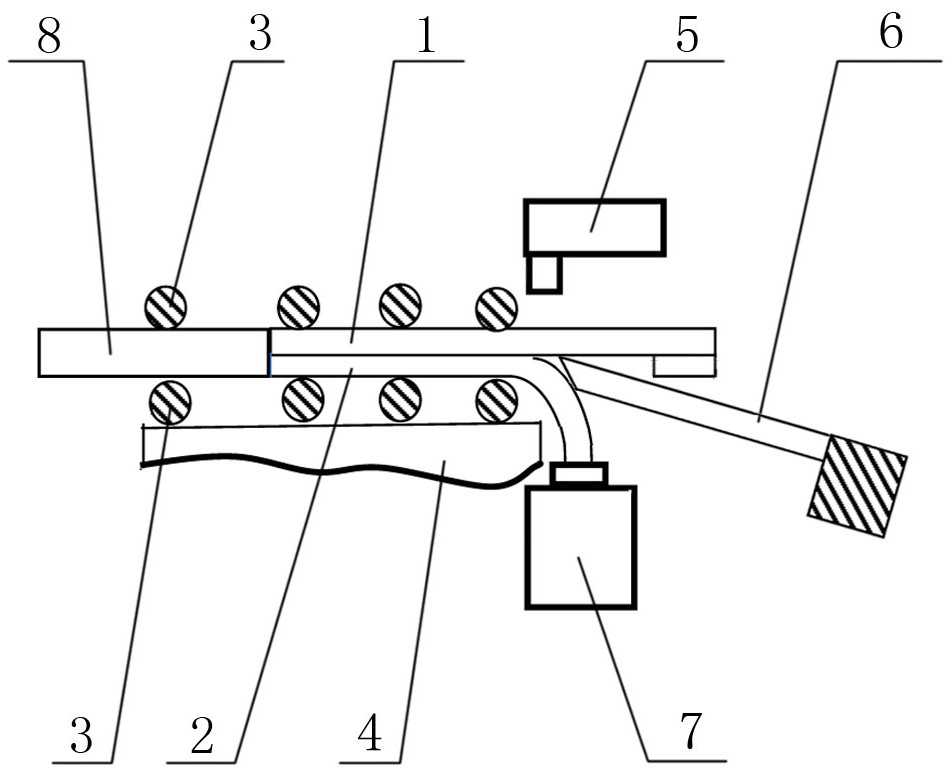

[0039] Such as Figure 1~3 As shown, the device for separating solar cell module glass provided by the present invention includes a transmission mechanism, a scraping mechanism, a laser scanning mechanism 5, a control mechanism, a clamping mechanism 7, a boosting mechanism, a blowing mechanism and a receiving mechanism.

[0040] The transmission mechanism is connected with the control mechanism, and it is used to drive the solar cell assembly to move under the control of the control mechanism. Such as Figure 4 As shown, the solar cell assembly includes an upper layer of glass 1 and a lower layer assembly 2 connected to the glass 1 through an adhesive film. The solar cell assembly is preferably a crystalline silicon solar cell assembly. In this embodiment, the lower layer assembly 2 includes silicon wafers from top to bottom. , film and back sheet; the conventional size of solar cell modules is 1 meter * 2 meters.

[0041] The transmission mechanism specifically includes a t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com