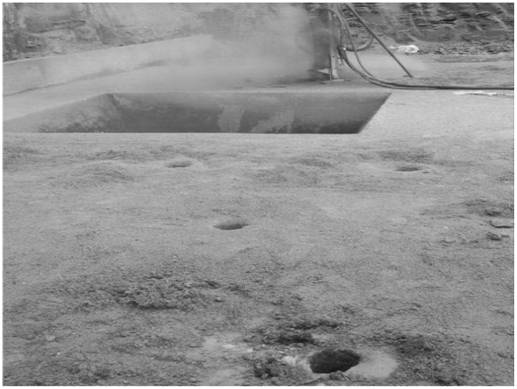

Post-construction process of anti-floating anchor rod

An anti-floating anchor and post-construction technology, applied in infrastructure engineering, sheet pile walls, protection devices, etc., can solve problems such as immersion and foundation soil disturbance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, and the schematic embodiments and descriptions of the present invention are used to explain the present invention, but are not intended to limit the present invention.

[0049] The general process of construction is: pouring the cushion layer 1 in the foundation pit, drilling the anti-floating anchor hole, placing the anti-floating anchor 2 in the anti-floating anchor hole, pouring the anti-floating anchor hole, and waterproofing the anti-floating anchor hole For construction, the anti-floating anchor rod 2 is bent, and the anti-floating plate steel bars are bound, and the anti-floating anchor rod 2 steel bars are located in the space formed by binding the anti-floating plate steel bars.

[0050] The detailed construction process is as follows:

[0051] 1. Base excavation

[0052] (1) Measurement: specific foundation positioning and laying out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com