Industrial control system multi-loop oscillation causality analysis method based on improved CCM

A technology of industrial control system and causal relationship, which is applied in general control system, control/regulation system, comprehensive factory control, etc., can solve problems such as influence, causal analysis interference, and reduce the accuracy of causal analysis, so as to improve analysis efficiency and eliminate Interference term, the effect of reducing the workload of causal analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] The present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be noted that the following embodiments are intended to facilitate the understanding of the present invention, but do not limit it in any way.

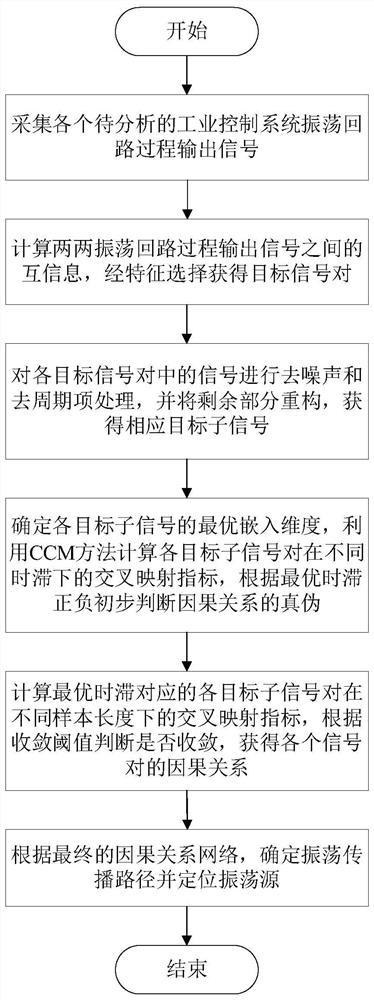

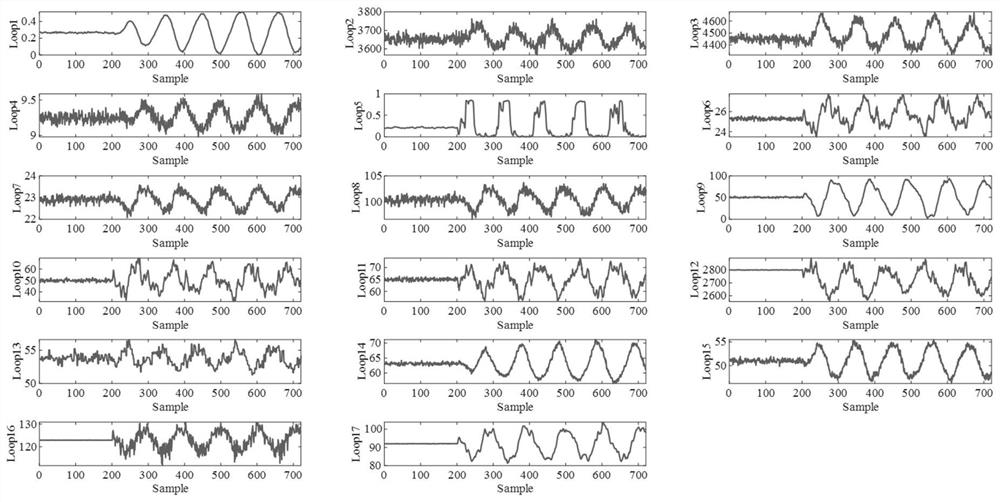

[0073] Taking the oscillation loop in the TE process based on the distributed control strategy as an example, the improved CCM causality analysis method for the chemical process with multiple oscillation loops is described in detail below.

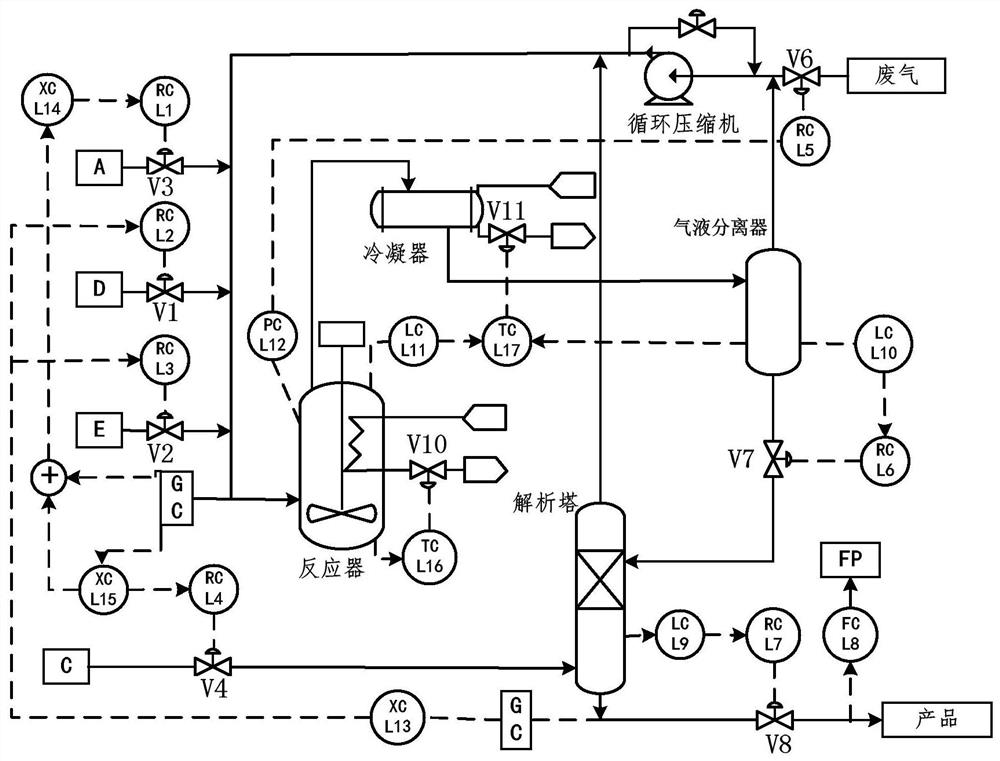

[0074] The TE process in this embodiment adopts a distributed control strategy, and the process and control strategy are as follows figure 1 Shown, according to "Ricker N L. Decentralized control of the Tennessee Eastman challenge process [J]. Journal of Process Control, 1996, 6 (4): 205-221.".

[0075] TE process is a chemical process model designed by Eastman Chemical Company based on actual industrial process. The whole process mainly includes five opera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com