Transuranic fuel and its preparation method and transmutation method

A uranium fuel and fuel technology, applied in the field of transuranium fuel and its preparation, to achieve the effect of simple and feasible preparation and guaranteed safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

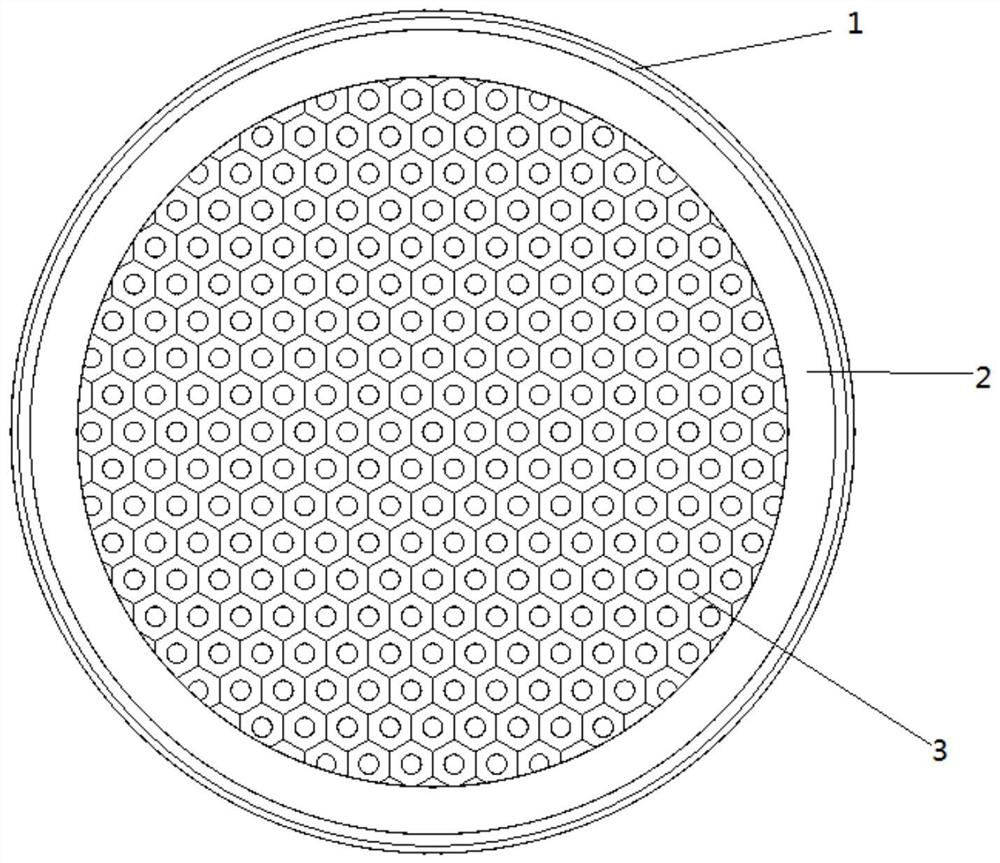

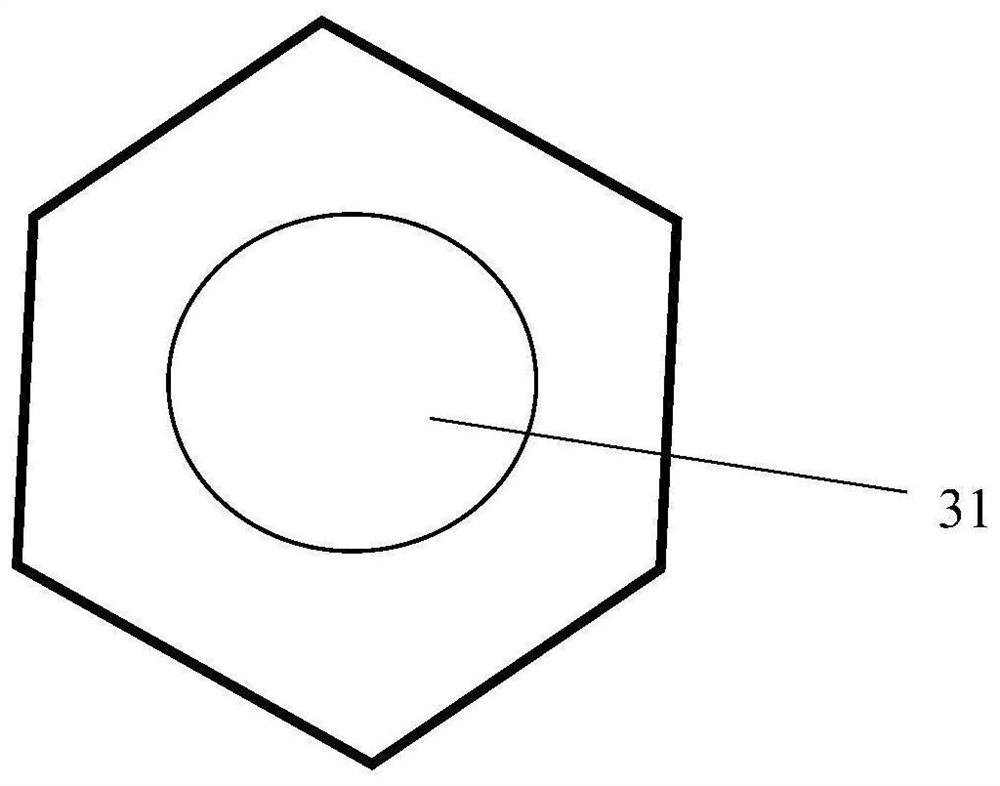

Embodiment 1

[0049] The transuranic fuel is used as the fuel of the liquid molten salt reactor and the liquid molten salt reactor is operated; wherein, the mole percentage of MA in the TRU of the transuranic fuel is 50%; the TRUF in the transuranic fuel is 50%. 3 The initial molar percentage of 0.134%; the volume ratio of transuranic fuel and graphite moderator 3 is 5%. Initially, the core temperature feedback was -2.7pcm / K. During operation, with the addition of TRUF 3 With a critical value of 1.0 to 1.01 for maintaining the core reaction, the energy spectrum becomes hard and the core temperature feedback becomes smaller.

Embodiment 2

[0051] TRUF in transuranic fuel 3 The initial molar percentage of 0.0844%; the volume ratio of transuranic fuel and graphite moderator 3 is 10%. Other conditions are the same as in Example 1. Initially, the core temperature feedback was -1.4pcm / K. During operation, with the addition of TRUF 3 With a critical value of 1.0 to 1.01 for maintaining the core reaction, the energy spectrum becomes hard and the core temperature feedback becomes smaller.

Embodiment 3

[0053] TRUF in transuranic fuel 3 The initial molar percentage of 0.0675%; the volume ratio of transuranic fuel to graphite moderator 3 is 15%. Other conditions are the same as in Example 1. Initially, the core temperature feedback was -0.81pcm / K. During operation, with the addition of TRUF 3 With a critical value of 1.0 to 1.01 for maintaining the core reaction, the energy spectrum becomes hard and the core temperature feedback becomes smaller.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com