A ladle hot repair dust removal equipment

A technology for dust removal equipment and ladle, applied in the direction of removing smoke and dust, foundry equipment, metal processing equipment, etc., can solve the problems of poor dust removal effect and low efficiency, to avoid the loss of air volume, avoid diffusion, and solve the effect of poor dust removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

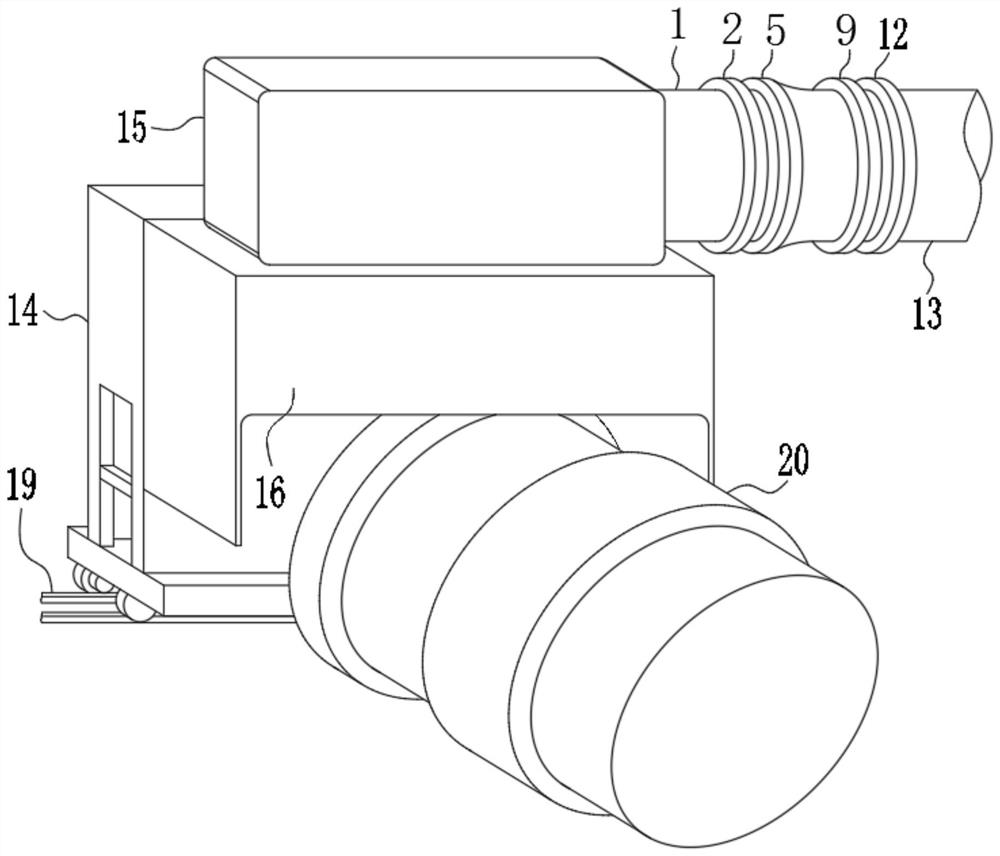

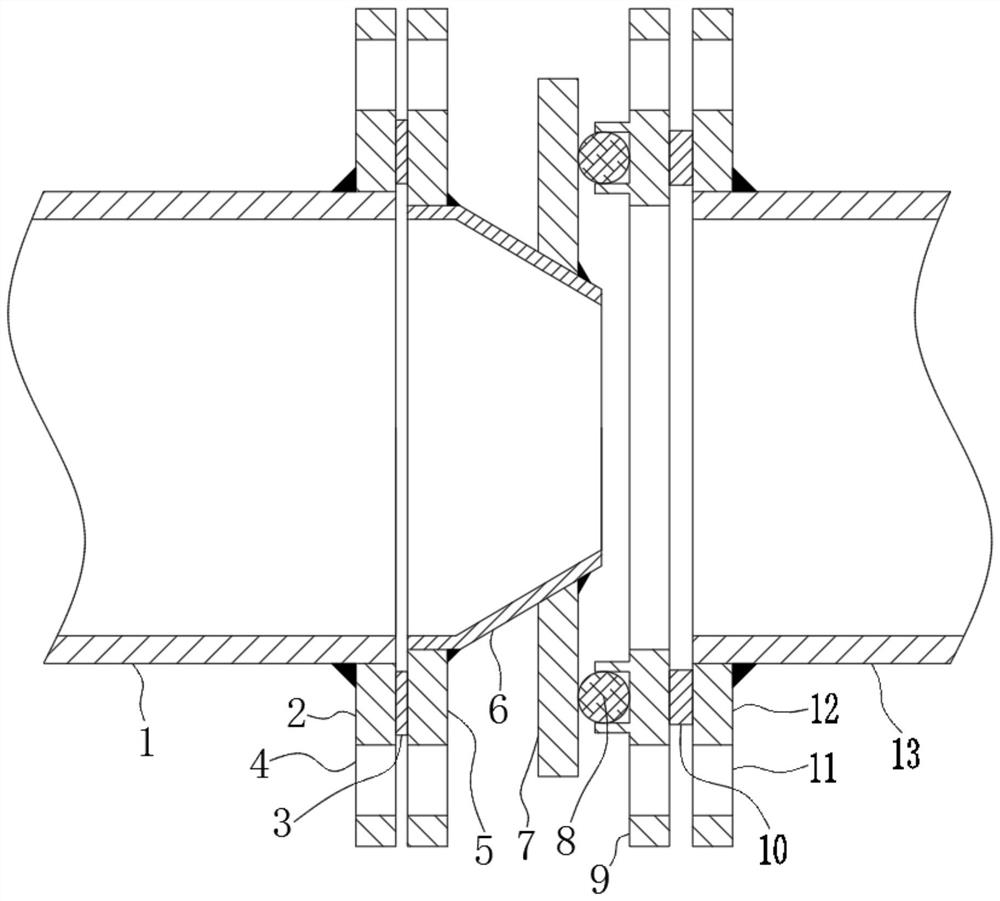

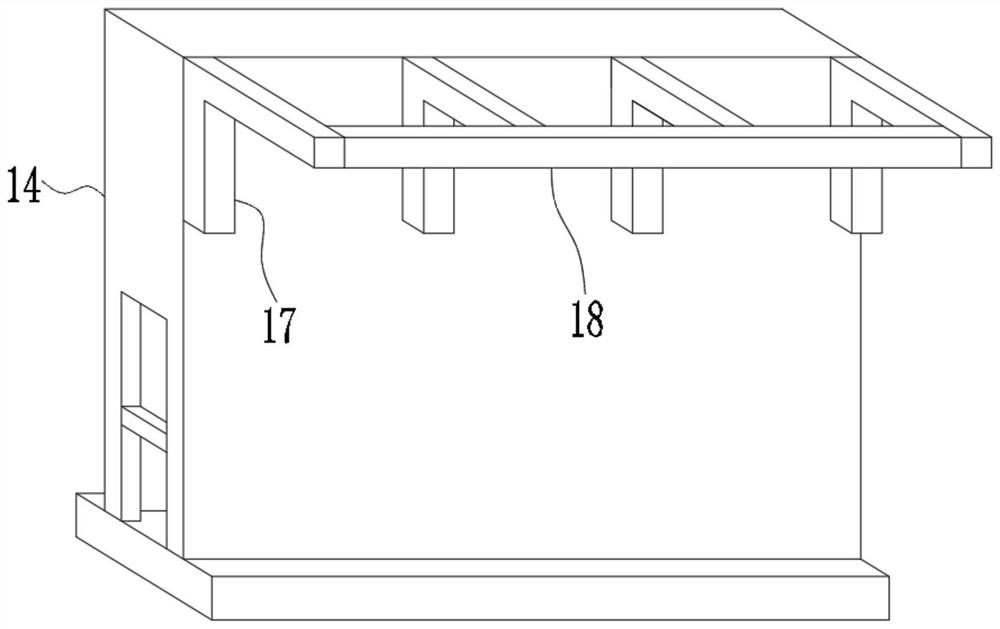

[0032] A ladle hot repair dust removal equipment, such as figure 1 As shown, it includes a collection cover 16 , a suction pipe 1 and a negative pressure pipe 13 . The catch cover 16 is installed on the side of the movable fire baffle 14 facing the steel ladle 20 , and the area of the catch cover 16 covers the mouth area of the steel ladle 20 . Optionally, the catch cover 16 hangs over the opening of the steel ladle 20 to cover the opening of the steel ladle 20 to the greatest extent. A dust suction hole is provided on the collecting cover 16 or the fire baffle 14, and one end of the dust suction pipe 1 communicates with the dust suction hole. The negative pressure pipe 13 communicates with the other end of the dust suction pipe 1, and the other end of the negative pressure pipe 13 communicates with the dust removal pipe network. An electric valve for controlling the air volume is arranged in the negative pressure pipe 13, and optionally, the electric valve is an electri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com