A multifunctional clamping device applied to smart industry

A clamping device and multi-functional technology, applied in the field of multi-functional clamping devices, can solve the problems of incompatibility and instability of clamping, and achieve the effects of good clamping ability, convenient clamping and fixing, and health protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

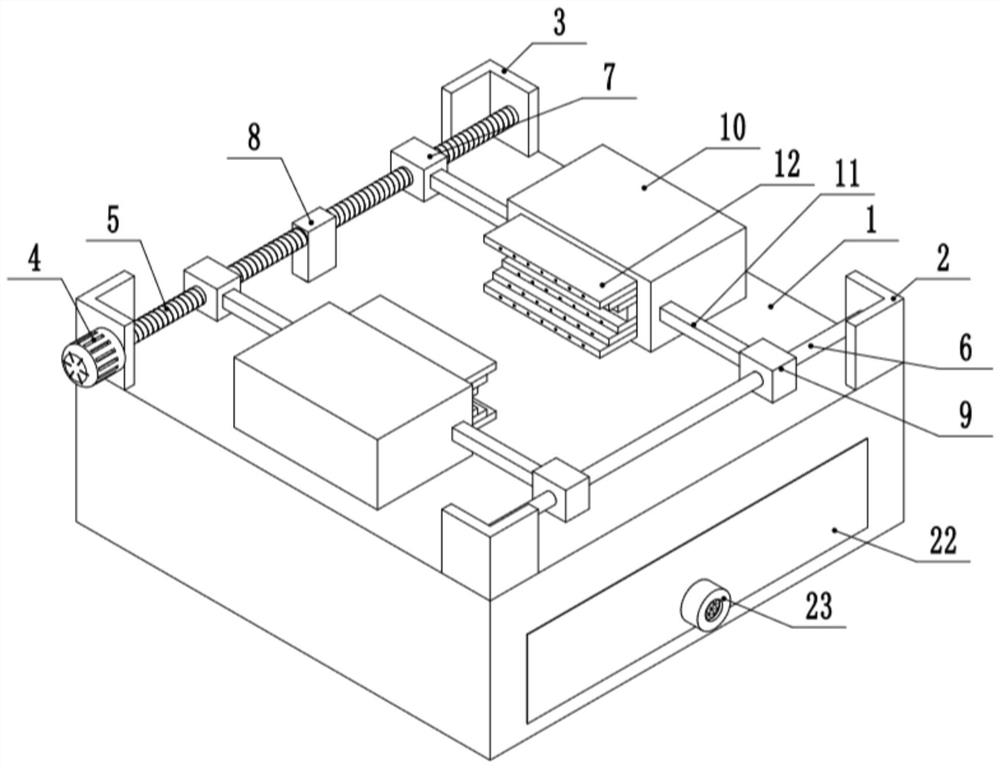

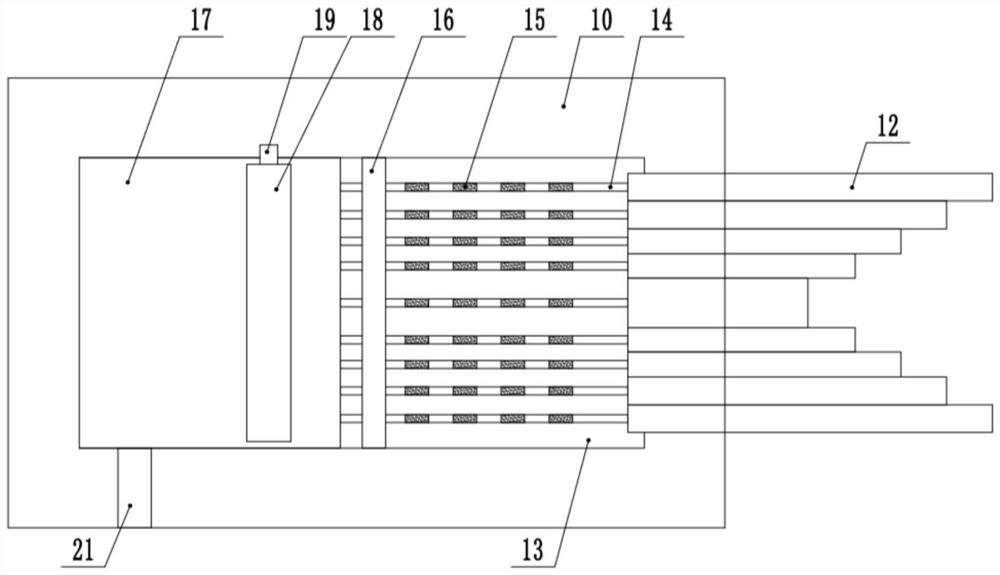

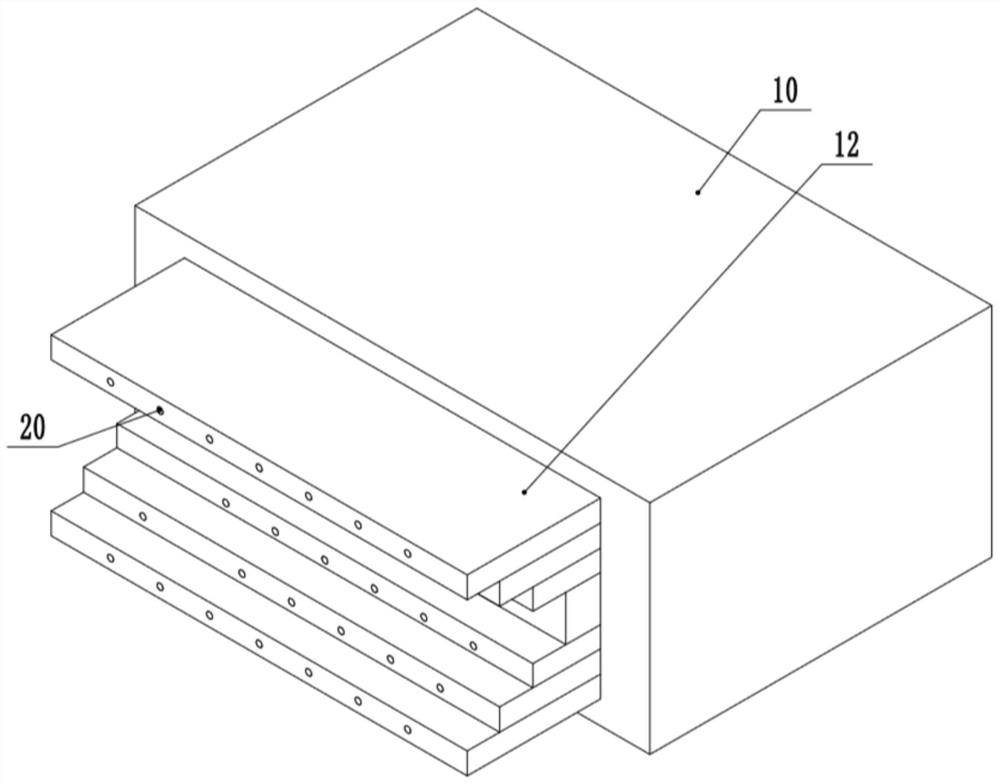

[0028] see Figure 1-6 , a multi-functional clamping device applied to smart industry, including a workbench 1, two first end seats 2 and two second end seats 3 are respectively fixed on the two ends of the top of the workbench 1, two first end seats 3 The guide rod 6 is fixedly connected between the end bases 2, and the drive screw 5 is fixedly connected between the two second end bases 3. One of the second end bases 3 is fixedly connected to the first drive motor 4, and the output shaft of the first drive motor 4 is connected to the The drive screw 5 is coaxially fixedly connected, two clamping seats 10 are slidably provided on the workbench 1, and self-adaptive clamping devices are arranged on the two clamping seats 10, and the external screw thread of the drive screw 5 is connected with a first The moving block 7, the outer sliding connection of the guide bar 6 is connected with the second moving block 9, and the connecting rod 11 is fixedly connected between the clamping ...

Embodiment 2

[0038] see Figure 1-6 , the other content of this embodiment is the same as that of Embodiment 1, the difference is that: the middle part of the drive screw 5 is connected to the partition block 8 by rotation, the partition block 8 is fixedly connected to the workbench 1, and the drive screw rods 5 on both sides of the partition block 8 The direction of the threads is reversed.

[0039] In the implementation process of the present invention, the first drive motor 4 is started to drive the two clamping seats 10 to move closer together to clamp the article. At the same time, the corresponding clamping plate 12 is pushed into the clamping seat 10, and the clamping plate 12 When moving, the conductive block 15 will pass through the fixed rod 16 and contact the conductive jacket 28, thereby generating a signal. According to this signal, the electromagnet 31 on the drive rod 29 on the side of the corresponding unmoved splint 12 is de-energized, and the The driving gear 26 is locked,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com