Control system of dry-mixed mortar floor station

A control system and technology for dry-mixed mortar, which are applied in mixing operation control, mixing operation control device, clay preparation device, etc., can solve the problems of fluctuation of mortar quality, inability to accurately control the amount of water added, and difficulty in controlling the uniformity of mixing. The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

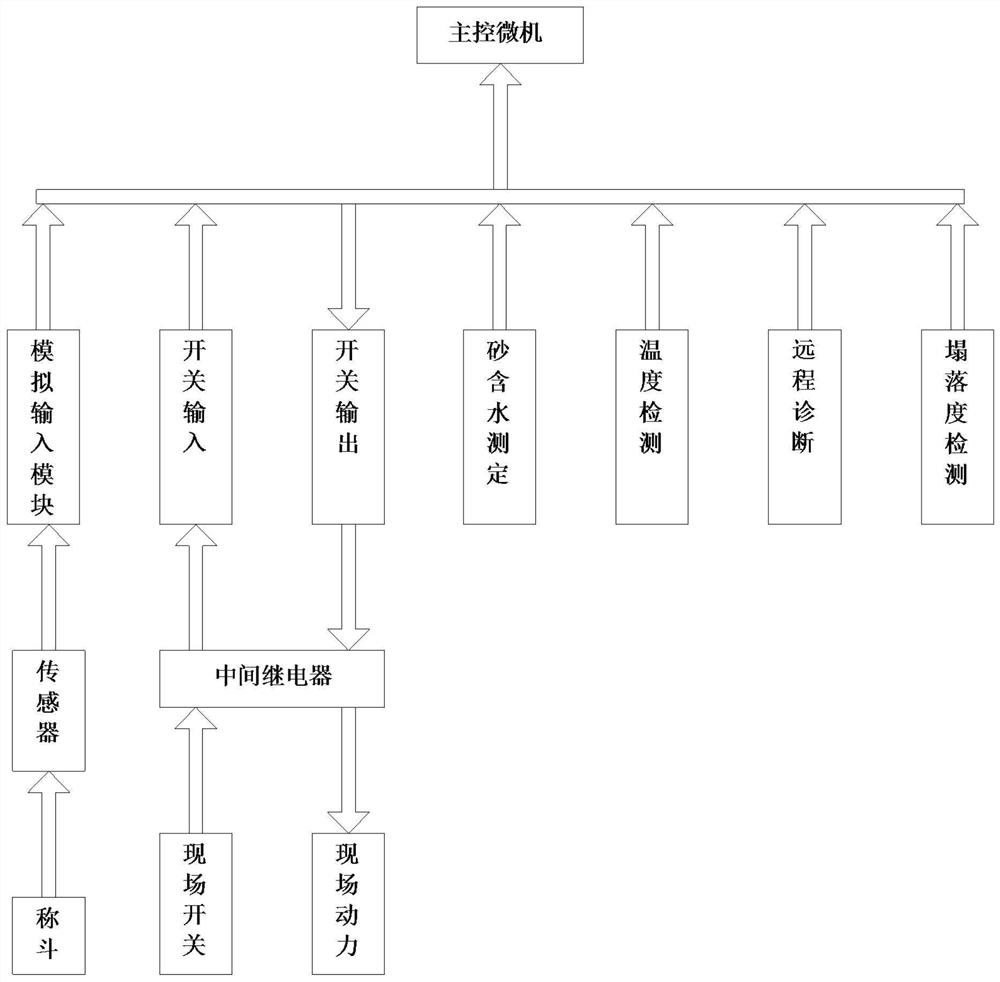

[0032] see figure 1 , a dry-mixed mortar building station control system, including the main control microcomputer of the remote control control system, the control system includes an analog input module for collecting weighing signal terminals, an intermediate signal module for transmitting intermediate signals, and an intermediate signal module for detecting sand materials. Sand water content measurement module for water content, temperature detection module for temperature detection, remote diagnosis module, slump detection module for detecting material slump in each silo.

[0033] Further, the analog input module includes a weighing sensor for transmitting aggregate weighing hopper, cement weighing hopper, fly ash weighing hopper, water weighing hopper, and additive weighing hopper, a PLC controller, and an amplifying board. The re-analog signal is transmitted to the amplifier board, and the PLC controller collects the information integrated and amplified by the amplifier ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com