Method for preparing isobutene by dehydrating tert-butyl alcohol

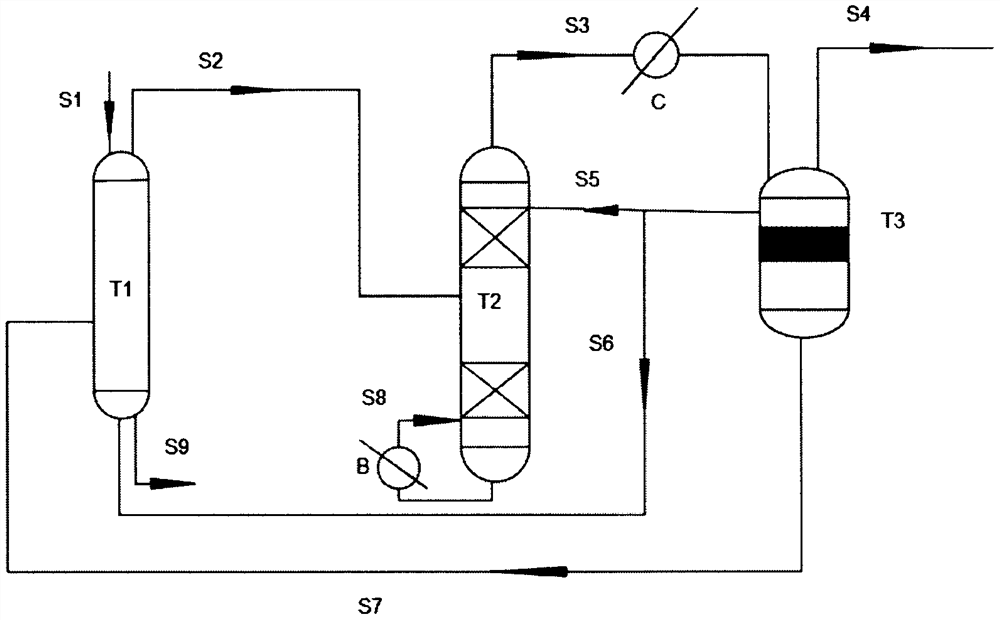

A technology for tert-butanol and isobutene, applied in the field of isobutene production by dehydration of tert-butanol, can solve the problems of affecting reaction efficiency, insufficient contact, high energy consumption for separation, etc., and achieves the effects of simple equipment connection, improved utilization rate, and simplified process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

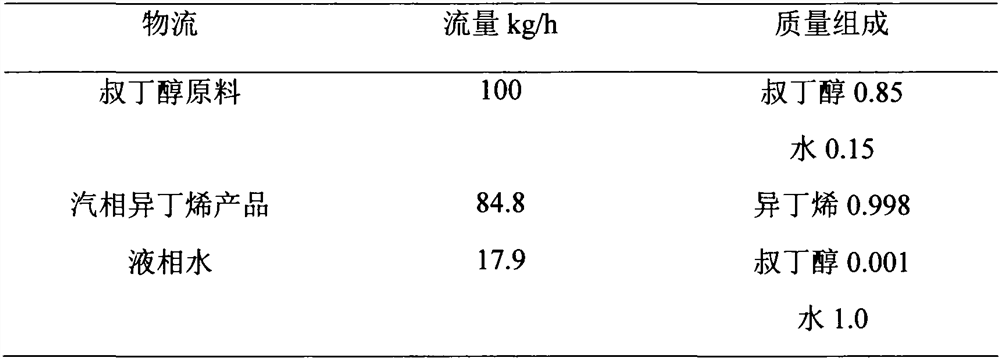

Embodiment 1

[0024] Use tert-butanol with a mass fraction of 85% as raw material to the reaction extraction tower, the feed temperature is 60°C, and the feed amount is 100kg / h. The material extracted from the top of the reaction extraction tower enters the azeotropic rectification tower, and the The operating pressure is 0.35Mpa, the reflux ratio is 1.5, the number of theoretical plates is 14, and 130g of entrainer is added to the phase separator. See Table 1 for the specific materials and results.

[0025] Table 1

[0026]

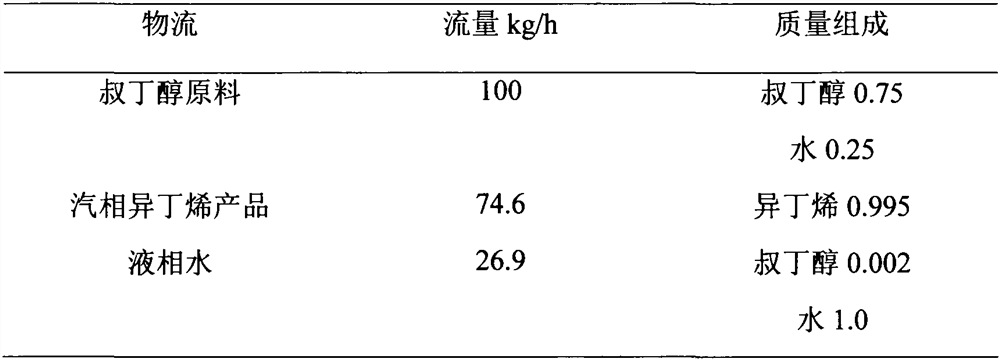

Embodiment 2

[0028] Use tert-butanol with a mass fraction of 75% as the raw material to the reaction extraction tower, the feed temperature is 60°C, and the feed rate is 100kg / h. The operating pressure is 0.35Mpa, the reflux ratio is 1.5, the number of theoretical plates is 8, and 130g of entrainer is added to the phase separator. The specific materials and composition of the results are shown in Table 2.

[0029] Table 2

[0030]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com