Low-temperature ultrahigh-toughness polypropylene blended composite material and preparation method thereof

A technology of ultra-high toughness and composite material, which is applied in the field of low-temperature ultra-high toughness polypropylene blended composite material and its preparation, polypropylene blended composite material and its preparation field, and can solve the unreported preparation method of quaternary blended composite material , complex process and other problems, to achieve the effect of low price, simple operation process and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7 and comparative example 1-6

[0030] (1) Pre-mixing: Mix carbon nanotubes, β-nucleating agent, ethylene-octene block copolymer with a glass transition temperature lower than -45ºC, and isotactic polypropylene in proportions by weight at room temperature for pre-mixing. mix. The specific formula is shown in Table 1.

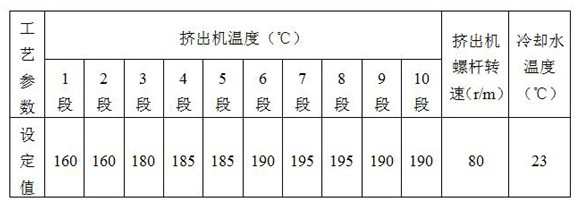

[0031] (2) Extrusion and granulation of carbon nanotubes / β nucleating agent / ethylene-octene block copolymer / polypropylene premix: use a conventional twin-screw extruder for industrial use to process the premix in step (1) Melt mixing and extrusion granulation. The extrusion process conditions adopted are: feeding section temperature (1-2 section) 160°C, shear blending section temperature (3-8 section) 180-195°C, extrusion section temperature (9-10 section) 190°C, The screw speed was 80 rpm, and the extruded strands were cooled in cold water at 23 °C, and then granulated by a granulator. The specific process parameters are shown in Table 2.

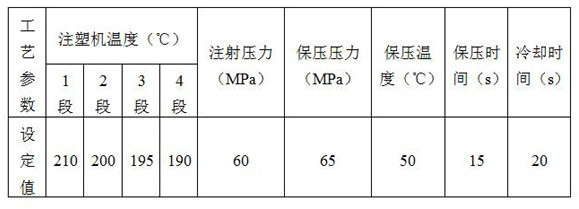

[0032] (3) Injection molding of carbon nanotubes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com