Mint fiber antibacterial fabric

A technology of mint fiber and antibacterial fabric, applied in the direction of textile and viscose made of artificial filament, yarn, etc., can solve the problem of poor antibacterial effect of clothing, and achieve long-lasting antibacterial effect, slow volatilization, and good skin-friendly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

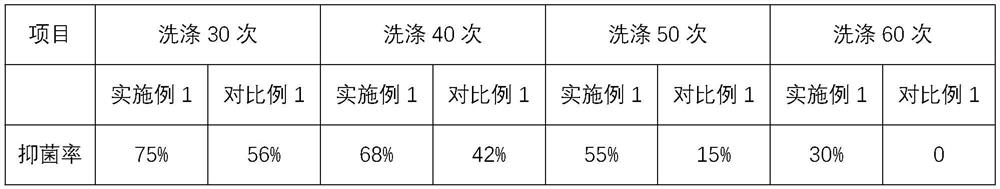

Embodiment 1

[0027] A mint fiber antibacterial fabric, the weft part is made of polyester fiber, mint fiber and combed long-staple cotton, and the warp is made of mint fiber and combed long-staple cotton; the weft part is made of polyester fiber 40% , 10% of mint fiber, 50% of combed long-staple cotton, and the warp part is blended with 20% of mint fiber and 80% of combed long-staple cotton; wherein the combed long-staple cotton is 60SJC / 2 cotton strand;

[0028] The mint fiber is prepared through the following steps: making fiber pulp—adding caustic soda to make cellulose—aging—carbon disulfide yellowing—adding porous starch mint oil micropowder—dissolving caustic soda—ripening—wet spinning—post-treatment—drying—finished product, wherein The mass percent that porous starch peppermint oil micropowder adds in cellulose is 10%;

[0029] The above-mentioned porous starch mint oil micropowder is prepared by the following process: mix porous starch and xanthan gum at room temperature, spray mi...

Embodiment 2

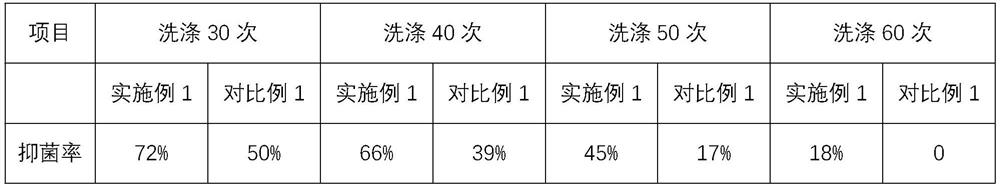

[0035] A mint fiber antibacterial fabric, the weft part is made of polyester fiber, mint fiber and combed long-staple cotton, and the warp is made of mint fiber and combed long-staple cotton; the weft part is made of polyester fiber 40% , 10% of mint fiber, 50% of combed long-staple cotton, and the warp part is blended with 20% of mint fiber and 80% of combed long-staple cotton; wherein the combed long-staple cotton is 60SJC / 2 cotton strand;

[0036] The mint fiber is prepared through the following steps: making fiber pulp—adding caustic soda to make cellulose—aging—carbon disulfide yellowing—adding porous starch mint oil micropowder—dissolving caustic soda—ripening—wet spinning—post-treatment—drying—finished product, wherein The mass percent that porous starch peppermint oil micropowder adds in cellulose is 10%;

[0037] The above-mentioned porous starch mint oil micropowder is prepared by the following process: mix porous starch and xanthan gum at room temperature, spray mi...

Embodiment 3

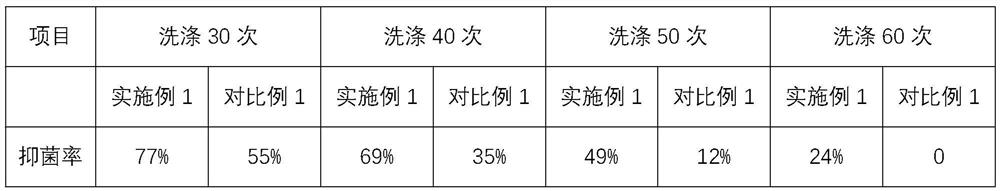

[0043] A mint fiber antibacterial fabric, the weft part is made of polyester fiber, mint fiber and combed long-staple cotton, and the warp is made of mint fiber and combed long-staple cotton; the weft part is made of polyester fiber 40% , 10% of mint fiber, 50% of combed long-staple cotton, and the warp part is blended with 20% of mint fiber and 80% of combed long-staple cotton; wherein the combed long-staple cotton is 60SJC / 2 cotton strand;

[0044] The mint fiber is prepared through the following steps: making fiber pulp—adding caustic soda to make cellulose—aging—carbon disulfide yellowing—adding porous starch mint oil micropowder—dissolving caustic soda—ripening—wet spinning—post-treatment—drying—finished product, wherein The mass percent that porous starch peppermint oil micropowder adds in cellulose is 20%;

[0045] The above-mentioned porous starch peppermint oil micropowder is prepared by the following process: mix porous starch and xanthan gum at room temperature, sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com