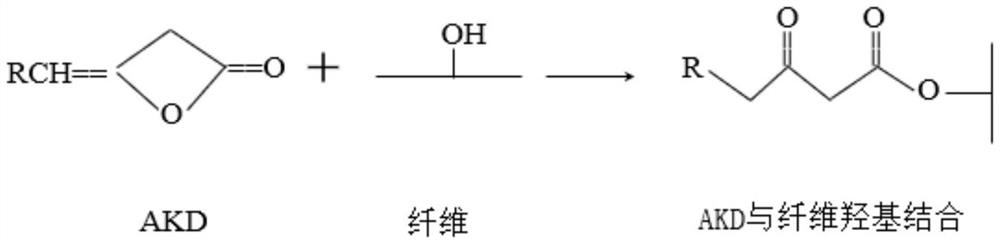

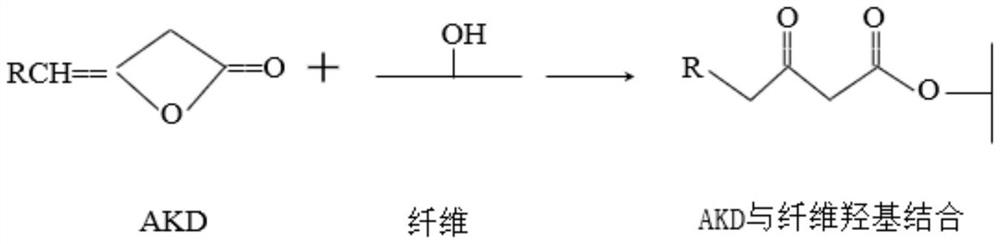

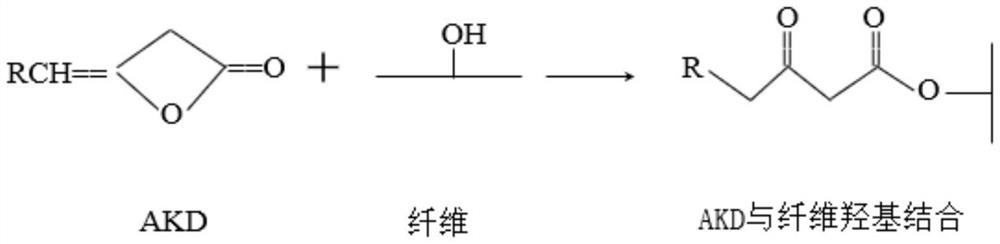

A kind of chitosan modified cationic starch emulsifier and the method for preparing AKD emulsion thereof

A cationic starch and chitosan modification technology, which is applied in the direction of water-repellent addition, inorganic compound addition, non-fiber pulp addition, etc., can solve the problems of lack of research on technology application and few research reports, and achieve remarkable sizing effect , good stability and improved sizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) By mass, 1 part of chitosan is dissolved in acetic acid with a mass concentration of 1%, and magnetically stirred to make it evenly dispersed.

[0023] (2) By mass, take 10 parts of cationic starch and gelatinize at 80°C for 30 minutes, then heat up to 90°C, add the chitosan solution and cross-linking agent prepared by dissolving step (1) under magnetic stirring, and add an appropriate amount of water , stirred and reacted for 90 minutes to prepare a modified cationic starch emulsifier.

[0024] (3) The above chitosan-modified cationic starch emulsifier was poured into 10 parts of AKD wax sheet liquid at one time, and stirred at a high speed of 10000 r / min for 3 minutes to prepare the AKD emulsion.

[0025]

Embodiment 2

[0027] (1) By mass, 1 part of chitosan is dissolved in acetic acid with a mass concentration of 1%, and magnetically stirred to make it evenly dispersed.

[0028] (2) By mass, take 10 parts of cationic starch and gelatinize at 80°C for 30 minutes, then heat up to 90°C, add the chitosan solution and cross-linking agent prepared by dissolving step (1) under magnetic stirring, and add an appropriate amount of water , stirred and reacted for 90 minutes to prepare a modified cationic starch emulsifier.

[0029] (3) The above chitosan-modified cationic starch emulsifier was poured into 15 parts of AKD wax sheet liquid at one time, and stirred at a high speed of 10000 r / min for 3 minutes to prepare the AKD emulsion.

[0030]

Embodiment 3

[0032] (1) By mass, 1 part of chitosan is dissolved in acetic acid with a mass concentration of 1%, and magnetically stirred to make it evenly dispersed.

[0033] (2) By mass, take 10 parts of cationic starch and gelatinize at 80°C for 30 minutes, then heat up to 90°C, add the chitosan solution and cross-linking agent prepared by dissolving step (1) under magnetic stirring, and add an appropriate amount of water , stirred and reacted for 90 minutes to prepare a modified cationic starch emulsifier.

[0034] (3) The above chitosan-modified cationic starch emulsifier was poured into 20 parts of AKD wax sheet liquid at one time, and stirred at a high speed of 10000 r / min for 3 minutes to prepare AKD emulsion.

[0035]

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com