Recyclable ultra-high performance concrete fabricated temporary pavement structure

A kind of pavement structure and ultra-high performance technology, applied in the direction of roads, roads, special pavements, etc., can solve the problems of inconvenient transportation and installation, complex structure of connectors, unfavorable driving safety, etc., to achieve convenient installation, simple structure, and reduce transportation costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

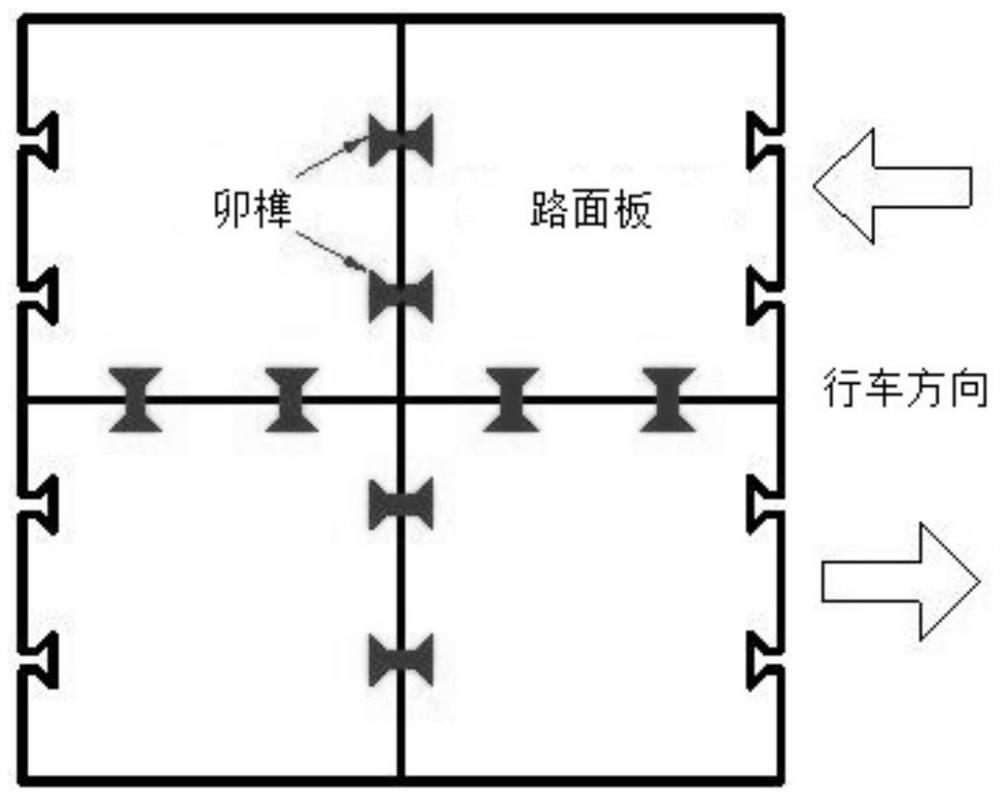

[0048] Such as figure 1 As shown, a recyclable ultra-high performance concrete prefabricated temporary pavement structure described in the present invention includes several road slabs, all of which are squares with the same length and width.

[0049] The road slab is an ultra-high-performance concrete component, and the side wall of the road slab is provided with a ridge, such as figure 1 As shown, each side of the square is provided with two mortises, which are located at 1 / 3 and 2 / 3 of the side length of the square, and the recesses of the mortises are formed by installing embedded parts when the road slab is prefabricated.

[0050] Such as figure 1 As shown, the mortises between the adjacent road panels are arranged correspondingly and are connected by tenons. for steel members.

[0051] Ultra-high performance concrete has ultra-high durability, ultra-high mechanical properties, excellent wear resistance and anti-blast performance, while the pavement structure has high ...

Embodiment 2

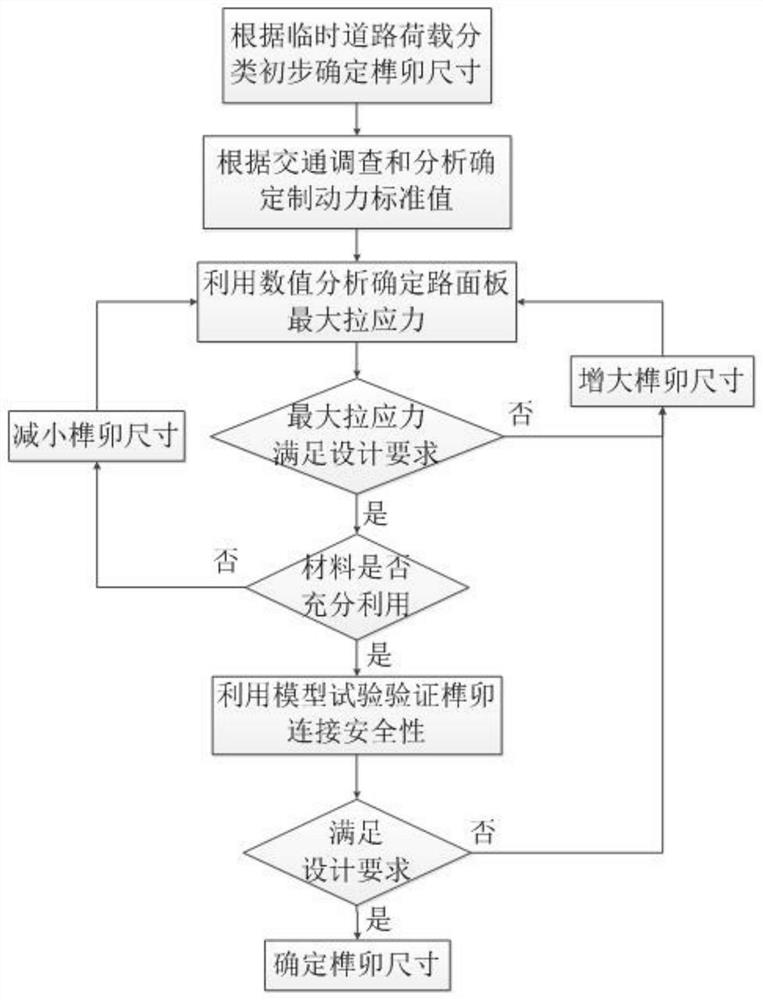

[0054] Such as Figure 1-3 As shown, the design method of the recyclable ultra-high-performance concrete prefabricated temporary pavement structure described in Embodiment 1 of the present invention includes the design of the road slab and the design of the mortise and tenon.

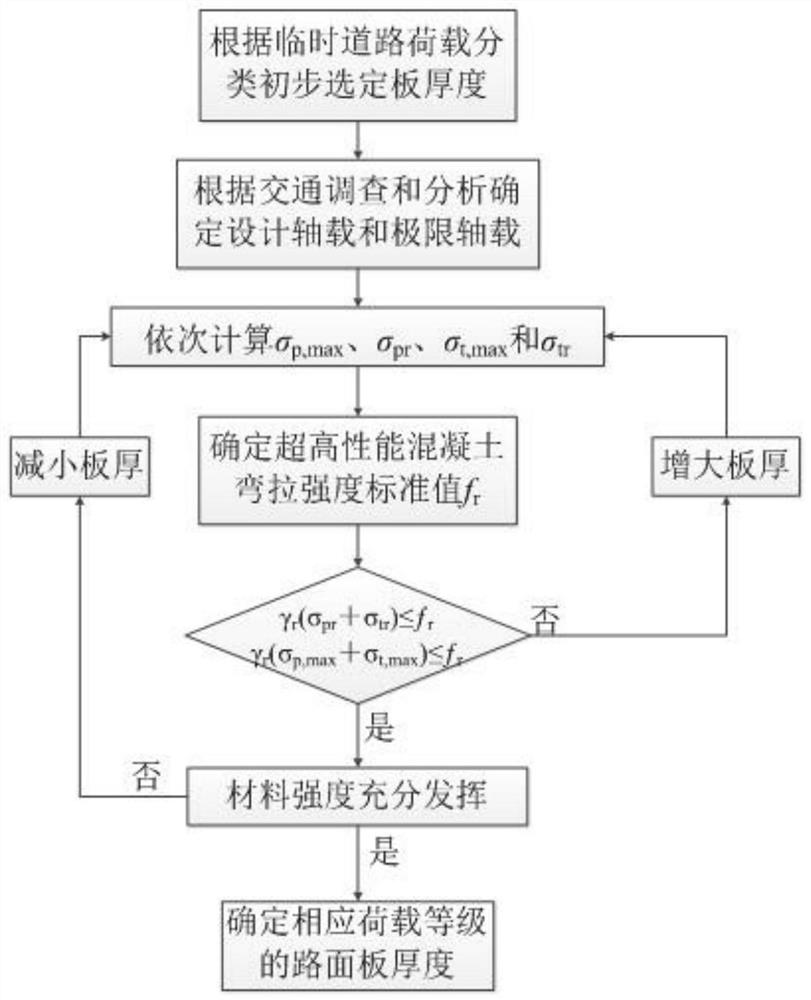

[0055] Such as figure 2 As shown, the design method of the road slab comprises the following steps:

[0056] A1. The slab thickness of the road slab is initially selected according to the classification of temporary road loads; specifically, the slab thickness of the heavy-duty temporary road slab is 200mm, the slab thickness of the ordinary vehicle load temporary road slab is 150mm, and the slab thickness of the pedestrian temporary road slab The thickness is 100mm;

[0057] A2. According to traffic investigation and analysis, determine the design axle load and ultimate axle load of the road slab;

[0058] A3. Based on the elastic foundation single-layer slab load stress calculation model, calculat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com