Bearing permeable concrete-ECC composite precast pile and preparation method thereof

A permeable concrete, -ECC technology, applied in sheet pile walls, manufacturing tools, construction, etc., can solve the problems of restricting the popularization and application of permeable pile technology, slow construction speed of permeable concrete piles, adverse effects on vertical bearing capacity, etc. Drainage efficiency and foundation consolidation rate, easy control of pile quality, and high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

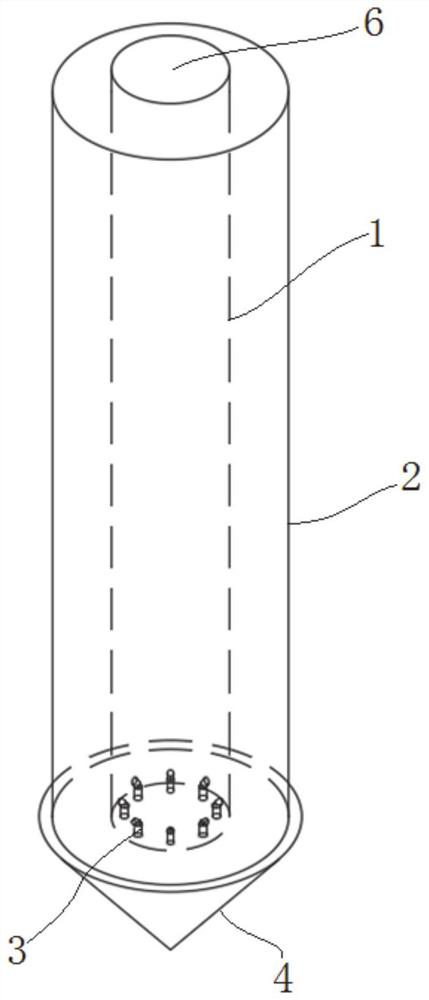

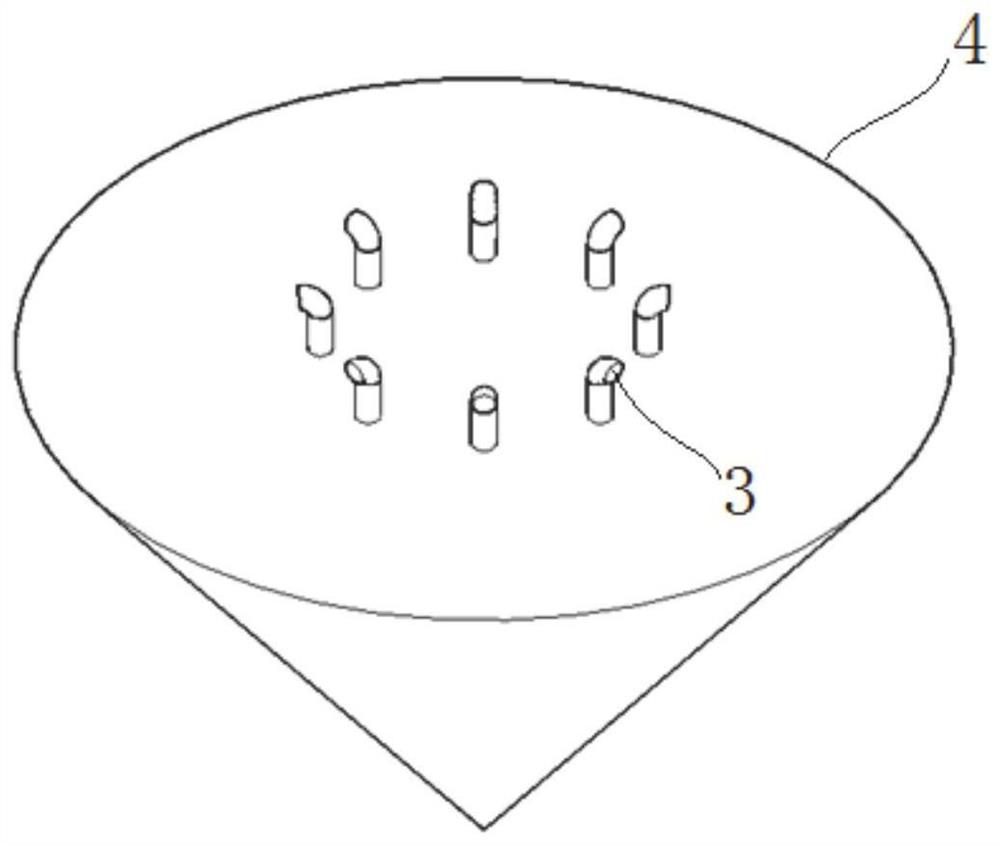

[0029] first embodiment ,refer to Figure 1-3 , an example of a load-bearing permeable concrete-ECC concrete composite prefabricated pile, including: an outer layer 1, an inner layer 2, a connector 3, a drill bit 4 and a pile top protection cap 5.

[0030] The inner layer 2 is a solid cylindrical structure made of ECC concrete, and the outer layer 1 made of permeable concrete is wrapped on the side wall of the inner layer 2 to form a pile body together. The composite double-layer structure formed by permeable concrete and ECC concrete has both the advantages of the two kinds of concrete. Among them, the excellent tensile strain-hardening performance and ductility of the inner ECC concrete provide good bending resistance for the pile body and allow piles A certain degree of horizontal displacement of the body occurs. At the same time, the permeable concrete on the outer layer ensures the water permeability of the pile body and can play the role of a vertical drainage channel...

no. 2 example

[0035] second embodiment : Figure 1-3 A kind of preparation method of load-bearing permeable concrete-ECC concrete composite prefabricated pile of example, pour out the conical high-strength concrete (strength grade is the concrete of C60 and above) first to make the drill bit 4, and bury a circle of diameter large in its bottom surface A steel bar with a diameter of about 30 cm is used as the connector 3. After the drill bit is cured for 28 days, the cylindrical ECC concrete is poured on the steel bar and vibrated. After the curing for 28 days, the inner layer 1 is formed and demoulded. Finally, pour permeable concrete on the outside of the ECC layer and vibrate it. After 28 days of curing, the outer layer 2 is formed and demoulded, and the upper end of the inner layer 2 is higher than the upper end of the outer layer 1 to form a protrusion 6.

[0036] Wherein, the diameter of the pile body formed by the inner layer 1 and the outer layer 2 is 18cm, the height of the inner ...

no. 3 example

[0038] third embodiment : the construction method of the load-bearing permeable concrete-ECC concrete composite prefabricated pile that above-mentioned embodiment prepares, comprises the steps:

[0039] (1) According to the design documents of the construction drawing and the surrounding environmental data, the points of the piles shall be measured and placed at the construction site, and the points shall be clearly marked.

[0040] (2) Install and debug the static pile driver, ensure that the center of the pressure head of the pile driver is aligned with the position of the pile point, and confirm that it is in place after the trial run check is normal.

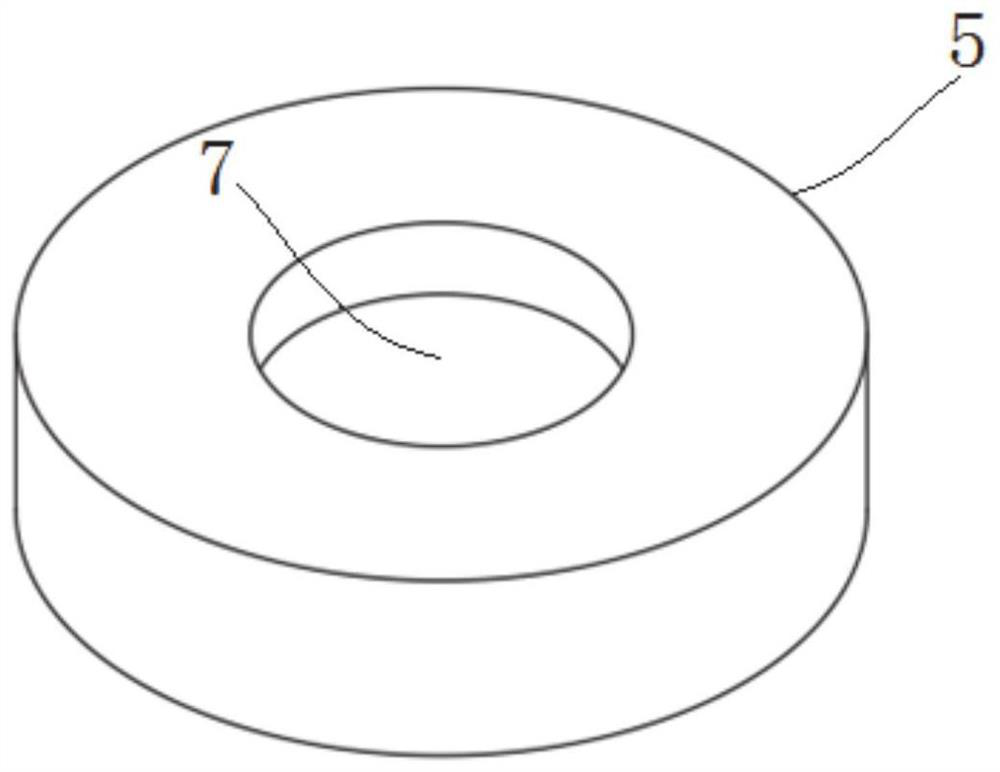

[0041] (3) Fasten the pile top protective cover on the pile body, lift the prefabricated double-layer concrete permeable pile, align the prefabricated pile with the target point, and vertically press it into the soil through the pressing effect of the pressure head.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Bottom diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com