Automobile front light-emitting sign

A technology for signs and automobiles, which is applied to semiconductor devices of light-emitting elements, light sources, and motor vehicles. It can solve the problems of difficult layout of light-emitting elements, limit the application effect of signs, and fail to achieve good sealing, so as to improve the appearance quality and improve the quality of signs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing and embodiment the technical solution of the present invention is described further:

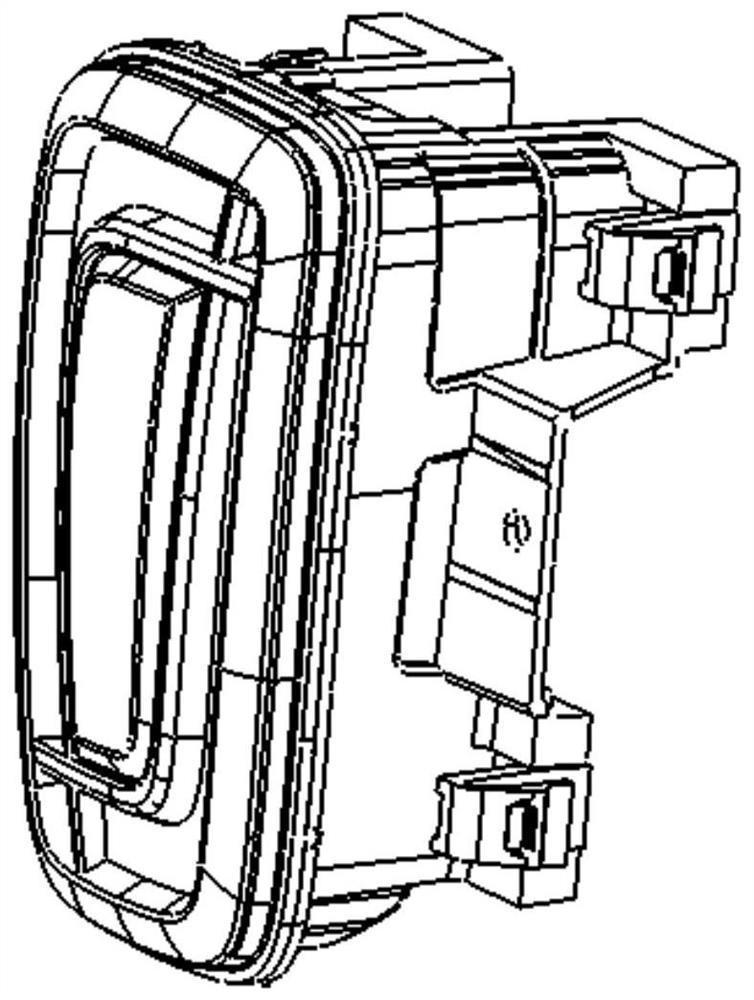

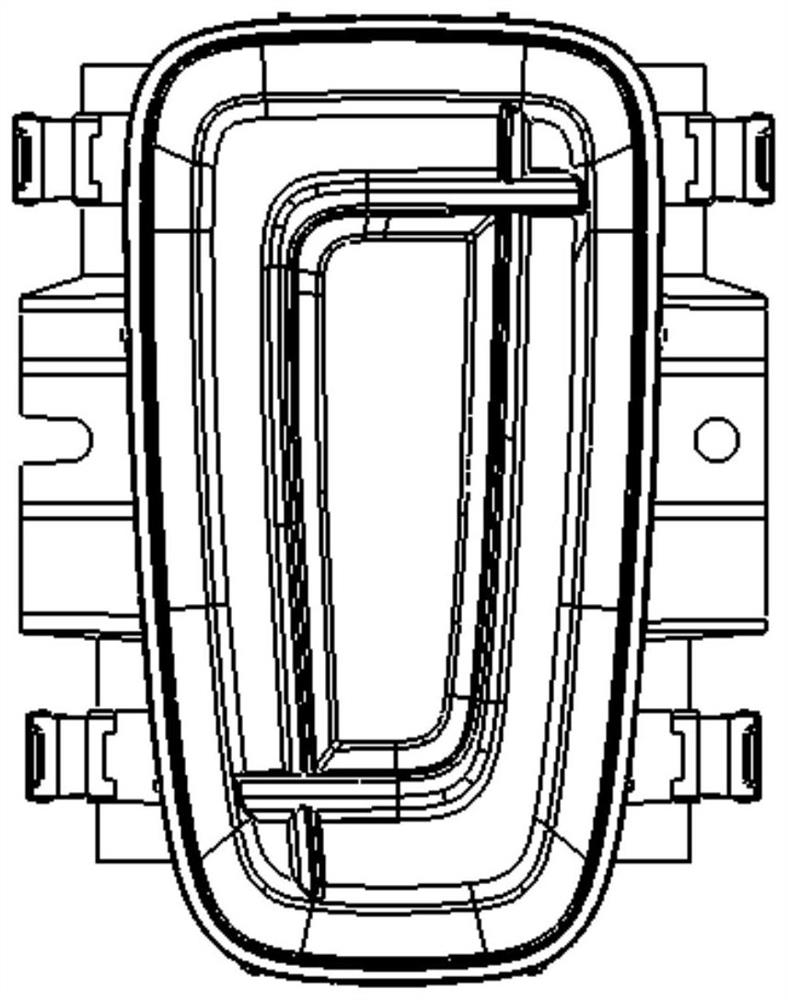

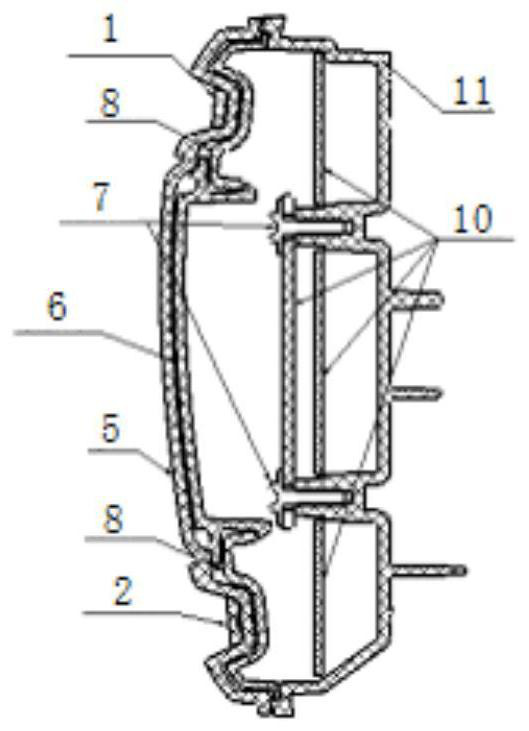

[0027] refer to Figure 1 to Figure 5 , a car front luminous sign, including: lampshade inserts, headlampshade 5, shade 6, special screw 7, light guide plate 8, self-tapping screw 9, LED module 10, lamp housing 11, air outlet cover assembly 12, Sheath sealing cover 13.

[0028] The lampshade insert and the front lampshade 5 are fixed by laser welding; the front lampshade 5, the lamp housing 11 and the light guide plate 8 are fixed and sealed by the vibration friction welding process; the shading part 6 and the light guide plate 8 are clamped and fixed; the LED module is fixed by special screws 7 is fixed with the light guide plate, and the LED module 10 is fixed on the lamp housing 11 by self-tapping screws 9; the air outlet cover assembly 12 and the sheath sealing cover 13 are installed on the lamp housing 11 for sealing waterproof and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com