Rapid drying device and method of damp corrugated board

A corrugated cardboard, fast drying technology, applied in drying, dryer, drying gas arrangement and other directions, can solve the problem that corrugated cardboard is easy to stick to objects, affects the flatness of corrugated cardboard, and slows the drying efficiency of corrugated cardboard. problems, to avoid deformation, ensure flatness, and ensure the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

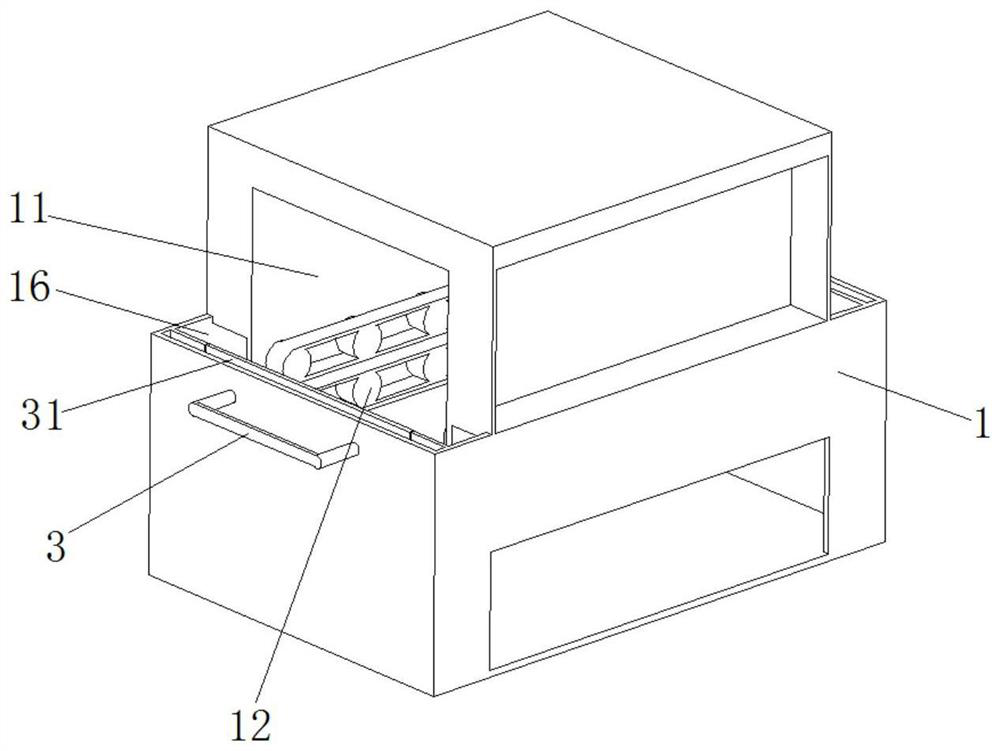

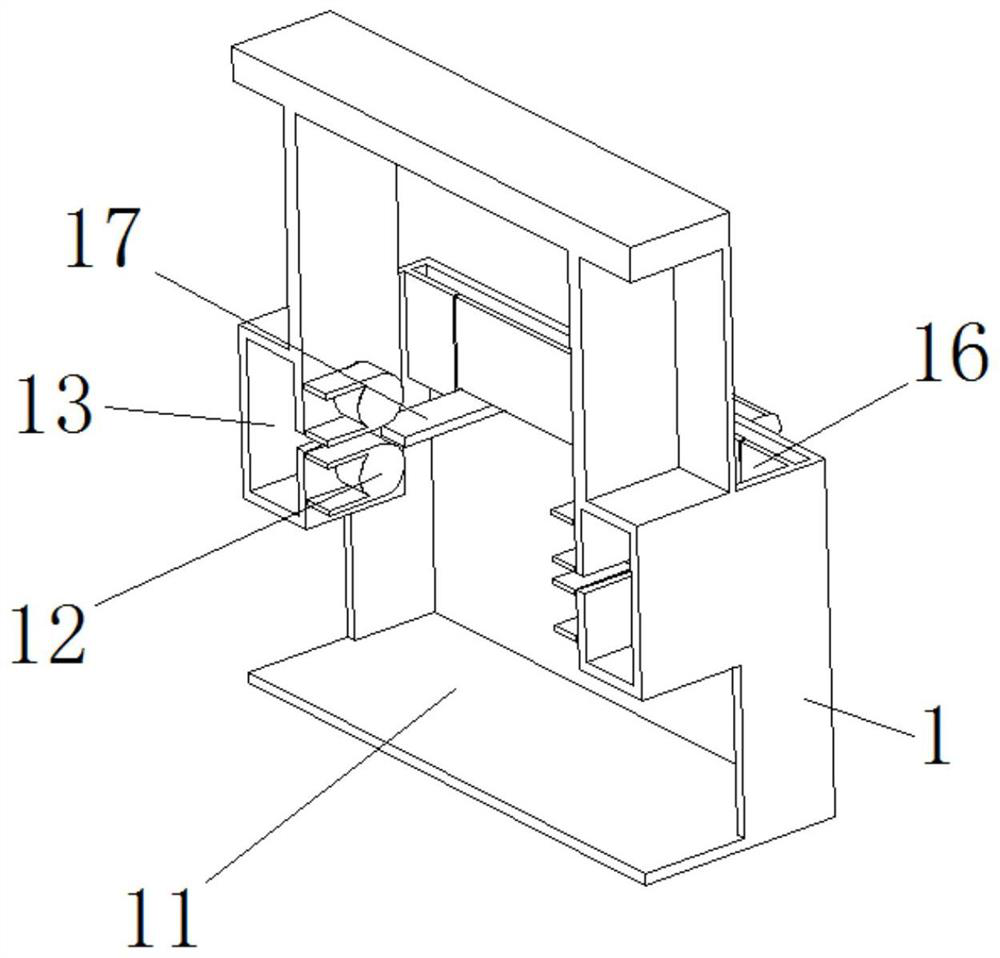

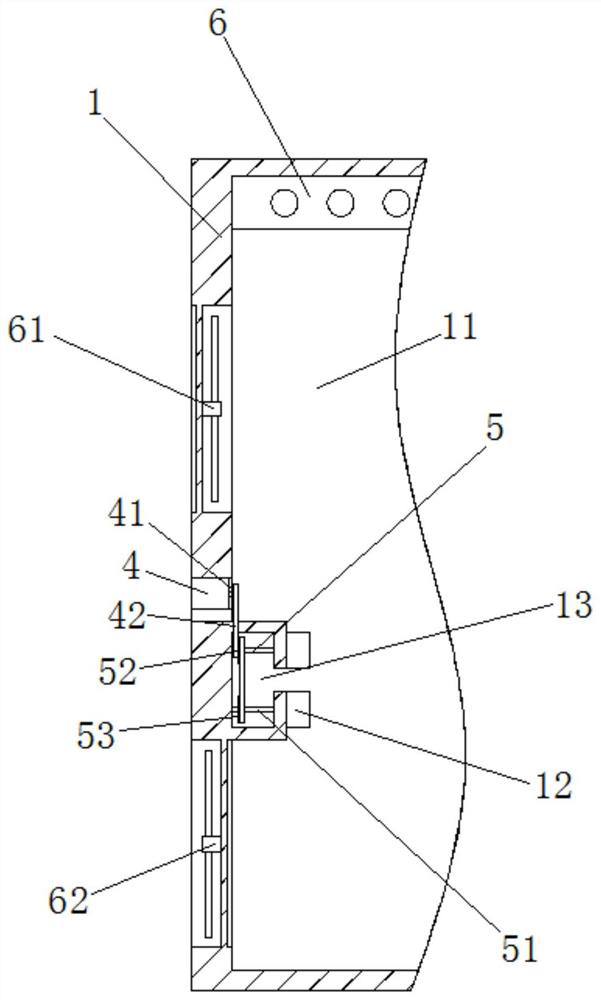

[0030] Such as Figure 1 to Figure 7 As shown, a quick drying device and drying method for damp corrugated cardboard, including a body 1 and a clamping mold 2, a drying tank 11 is provided in the body 1, and both sides of the drying tank 11 are symmetrical in the body 1 A conveyor belt 12 is provided, and both sides of the drying tank 11 are provided with chutes 13 between the conveyor belts 12. The chutes 13 run through the drying tank 11 and communicate with the body 1. The body 1 is located above the chute 13. The No. 1 rack 14 and the No. 2 rack 15 are symmetrically and fixedly ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap