Unmanned ship inspection system for offshore wind power plant and working method of system

An inspection system and unmanned ship technology, applied in transmission systems, traffic control systems, electrical components, etc., can solve the problem of unfavorable key equipment fault discovery and elimination, incomplete coverage of key equipment status monitoring, and insufficient intelligence of inspection equipment. Advanced problems, to achieve the effect of improving inspection efficiency and economic benefits, improving space and energy efficiency, and reducing load and electricity load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment, and its content is explanation of the present invention rather than limitation:

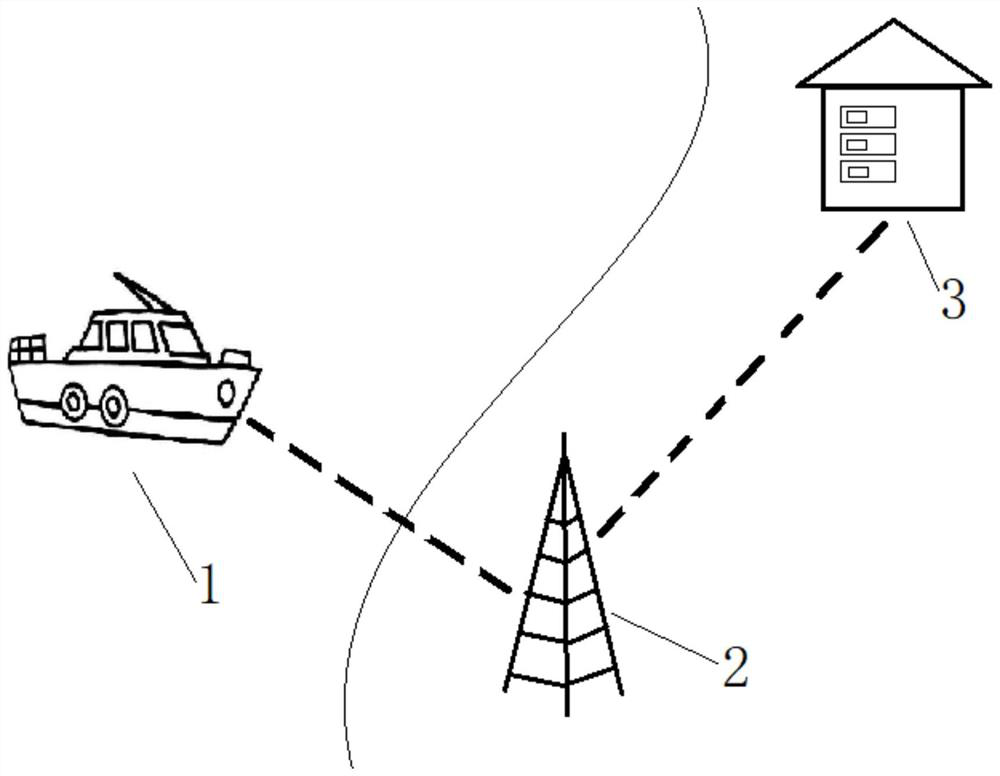

[0034] Such as image 3 , an unmanned ship inspection system for offshore wind farms according to the present invention, including an unmanned ship terminal 1, a shore-based base station 2 and a remote command center 3;

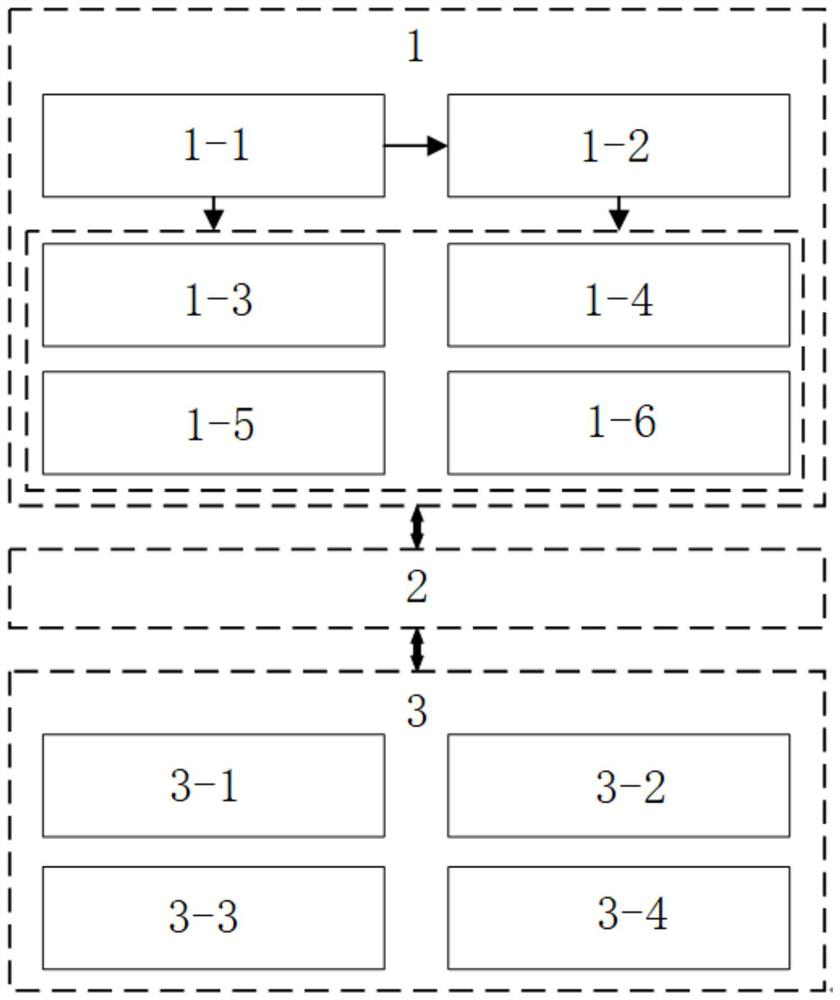

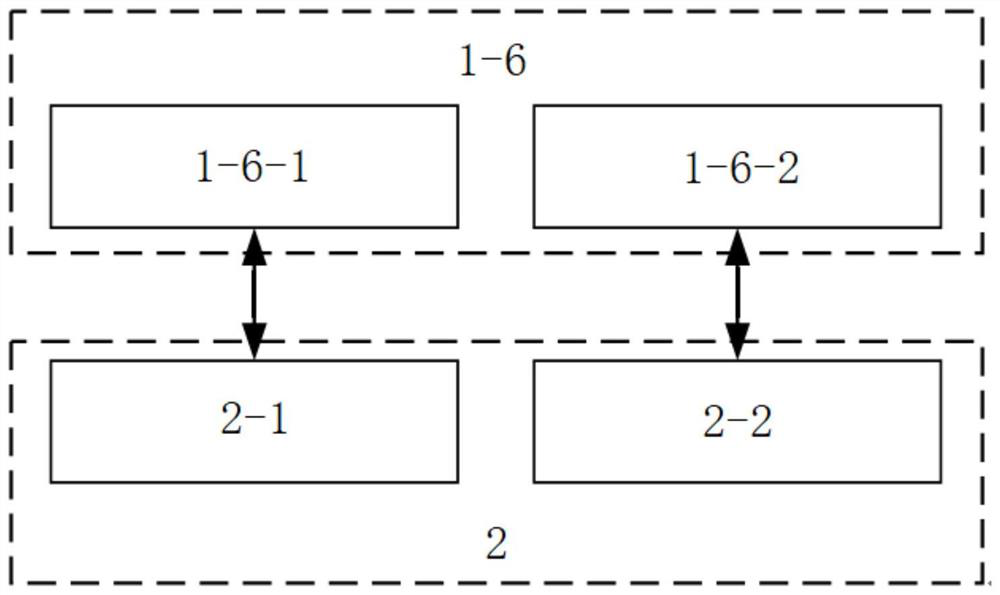

[0035] Such as figure 1 , the unmanned ship terminal 1 includes a control system 1-1, a power supply module 1-2, a power system 1-3, a sonar imaging inspection device 1-4, a motion detection module 1-5 and a communication module 1-6, and the control system 1 -1 is respectively connected with the power supply module 1-2, the power system 1-3, the sonar imaging inspection equipment 1-4, the motion detection module 1-5 and the communication module 1-6. The control system 1-1 includes an automatic anti-collision module and an unmanned ship drivin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com