A grading purification and treatment system for waste incineration flue gas in power plants

A technology for waste incineration and purification treatment, applied in separation methods, dispersed particle separation, dispersed particle filtration, etc., can solve the problems of difficult sampling, less purification times, incomplete purification of pollutants, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

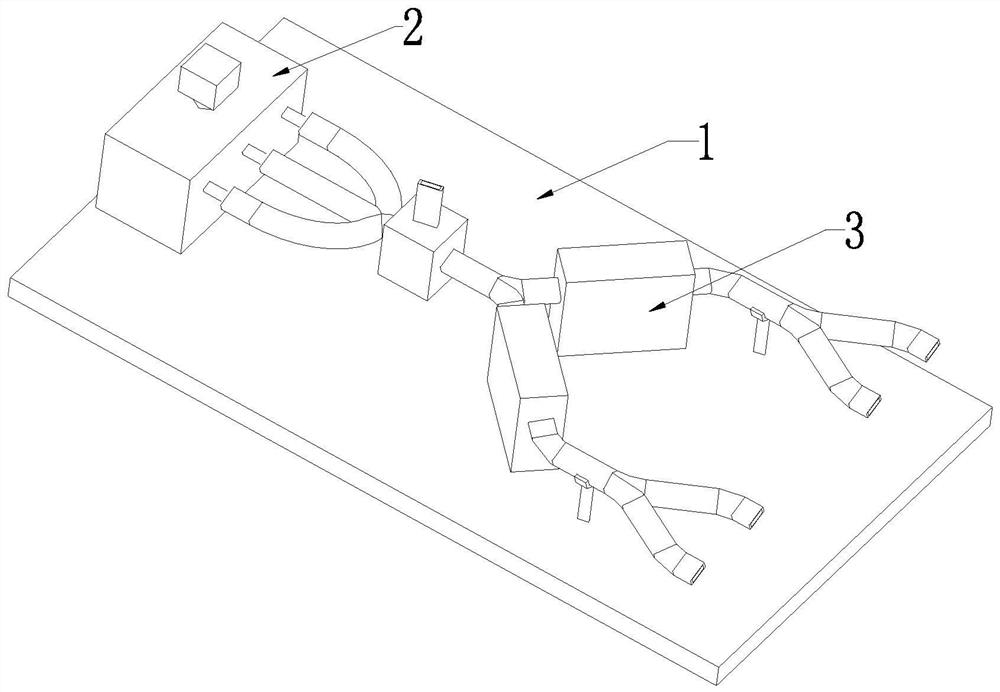

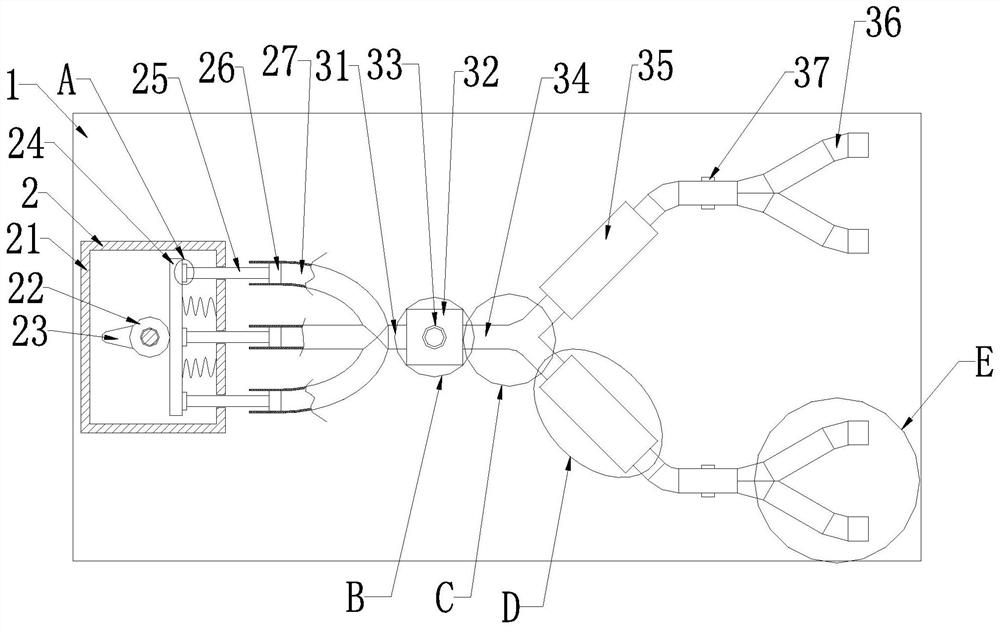

[0027] In order to make the technical means realized by the present invention, creative features, goals and effects easy to understand, the following combination Figure 1 to Figure 8 , to further elaborate the present invention.

[0028] A waste incineration flue gas classification purification treatment system in a power plant, including a mounting frame 1, an extruding set 2 and a purification set 3, and the extruding set 2 and the purification set 3 are sequentially arranged on the mounting frame 1 from left to right, wherein :

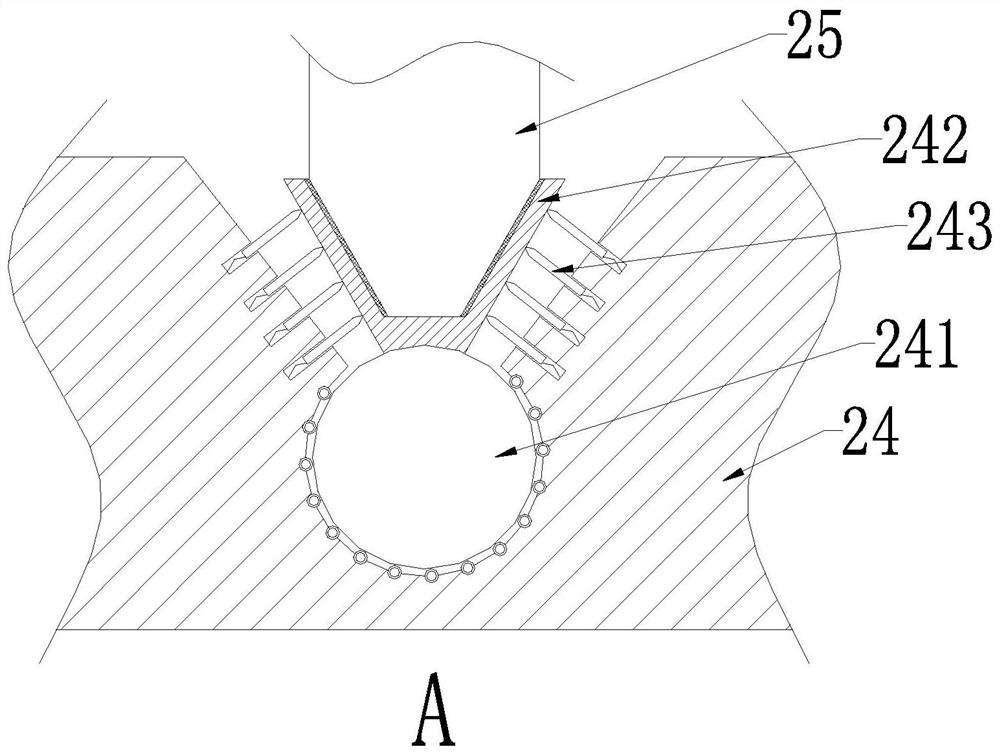

[0029] The extrusion set 2 includes an extrusion box 21, a No. 1 motor, a rotating wheel 22, an extrusion push block 23, a sliding pull plate 24, an extrusion push rod 25, a sealing rubber sleeve 26 and a connecting pipe 27. The extrusion box 21 Installed on the mounting frame 1 by welding, a No. 1 motor is installed on the extrusion box 21, a rotating wheel 22 is installed on the output shaft of the No. 1 motor, and an extrusion push block 23 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com