Cooperative industrial welding robot for intelligent automobile automatic production line

An automated production line and welding robot technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., to improve welding quality, avoid offset, and facilitate observation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

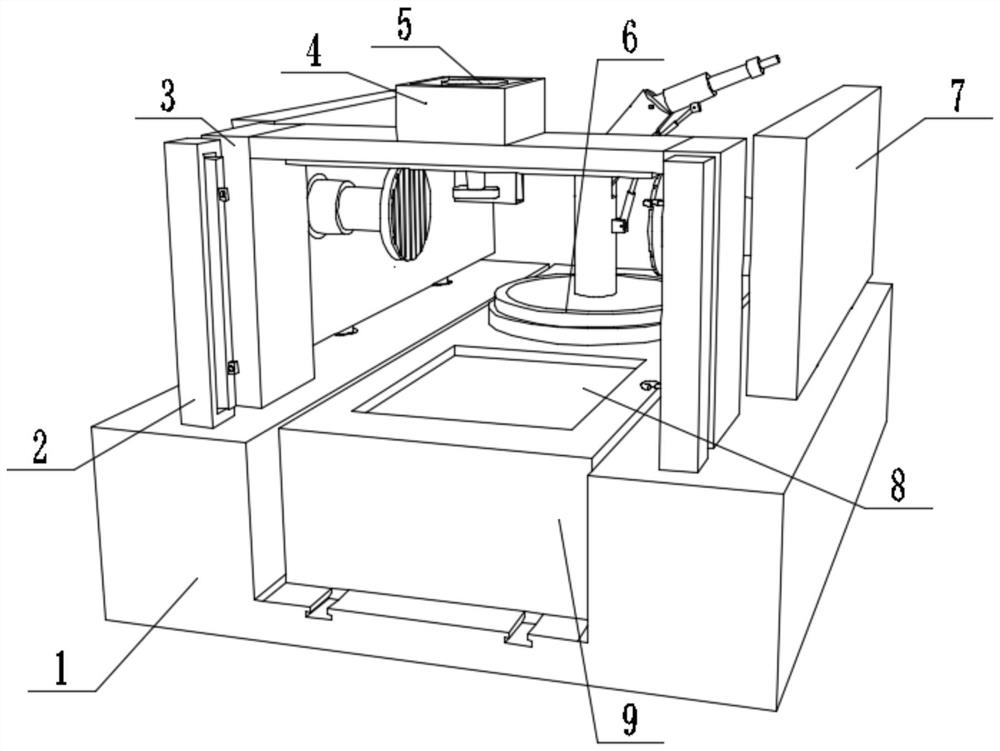

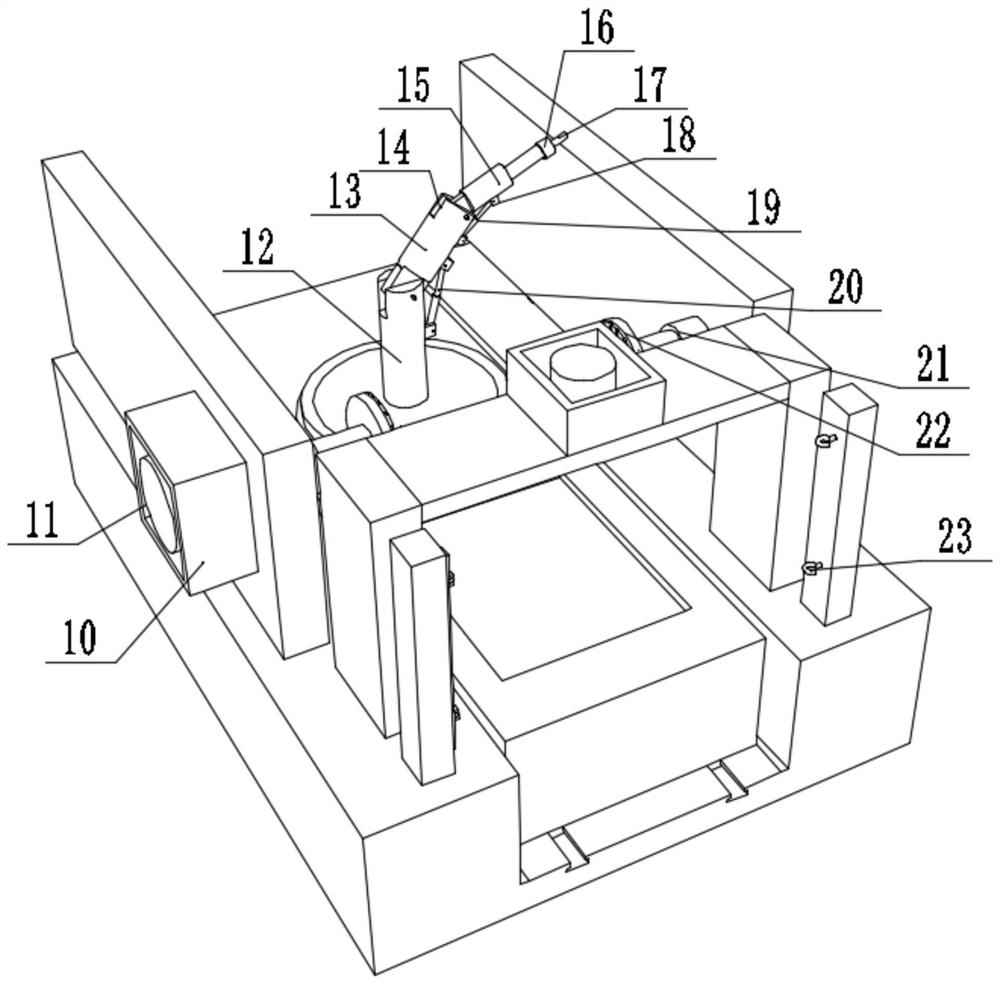

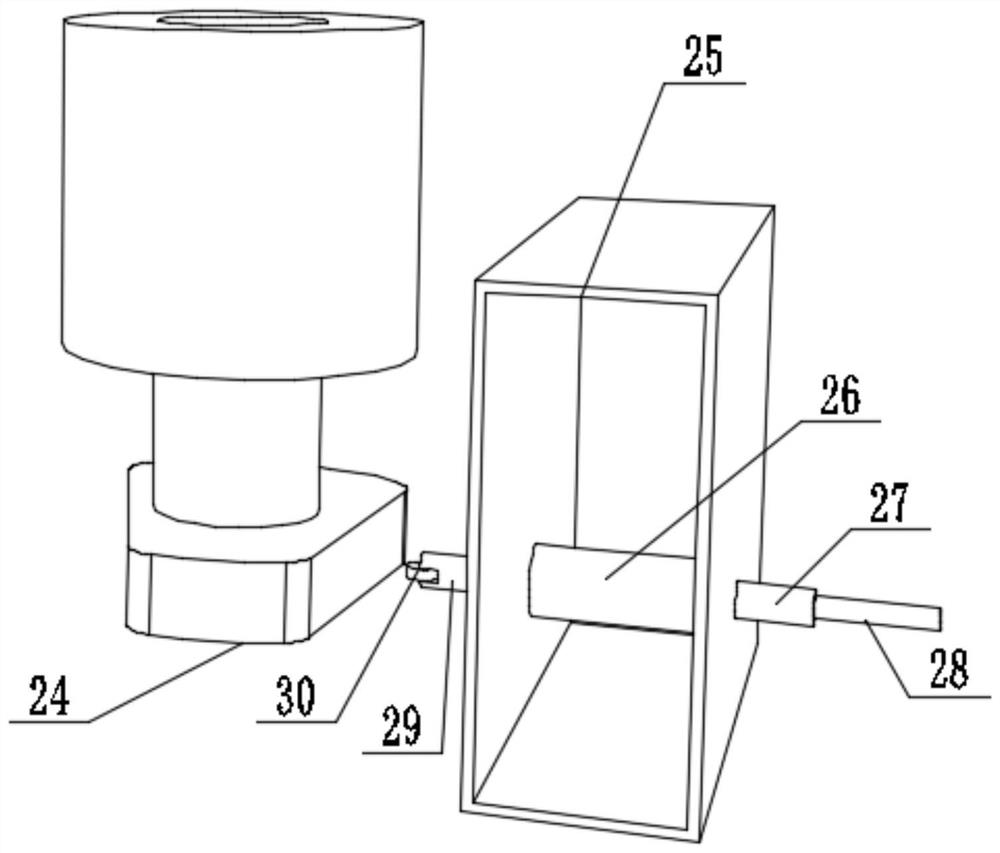

[0027] see Figure 1-5 , the present invention provides the following technical solutions: comprising a base 1, one end of the top outer wall of the base 1 is fixed with a support frame 3 by screws, the top inner wall of the support frame 3 is provided with an impact mechanism, and one end of the top outer wall of the base 1 is respectively provided with a storage column 2, The outer wall of one side of the storage column 2 is provided with a shielding mechanism, and several third hydraulic cylinders 41 are respectively embedded in the two sides of the outer wall of the top of the base 1, and the third hydraulic cylinders 41 are connected with a synchronous hydraulic system, and one end of the telescopic rod of the third hydraulic cylinder 41 passes through the The lifting plate 7 is threadedly connected, and one end of the outer wall on one side of the lifting plate 7 is provided with a clamping mechanism. The middle part of the outer wall on the top of the base 1 is slidingly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com