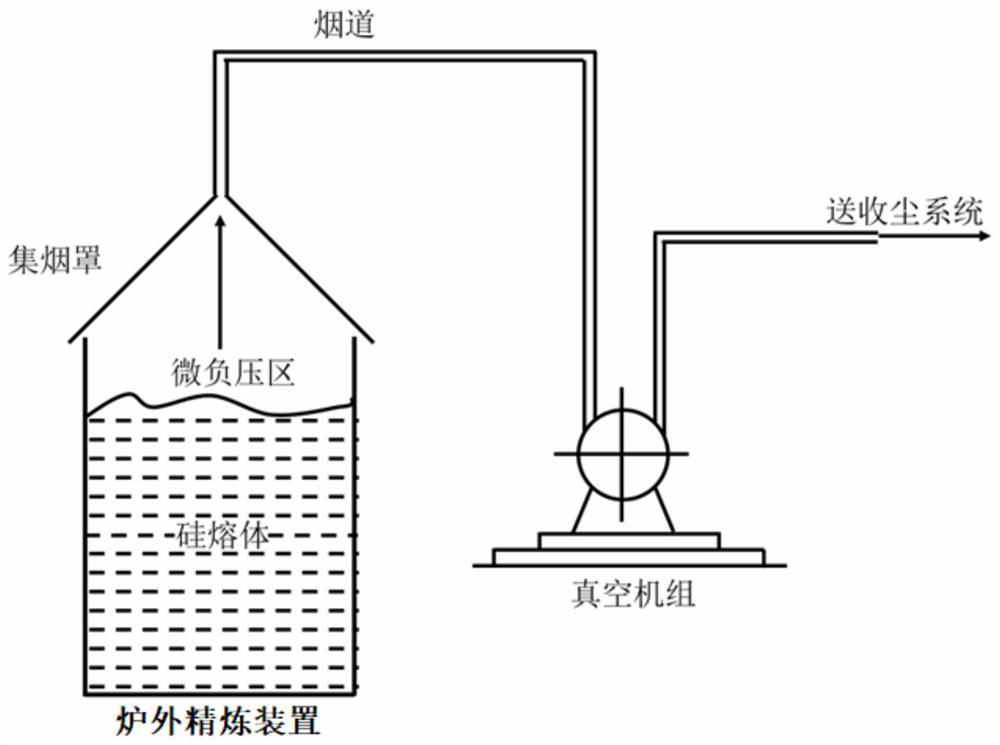

Micro-negative pressure external refining method for industrial silicon melts

A technology of refining outside the furnace and a micro-negative pressure furnace, which is applied in the fields of chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems of increasing energy input consumption and discharge of industrial wastes, etc., and achieves the effect of easy operation and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

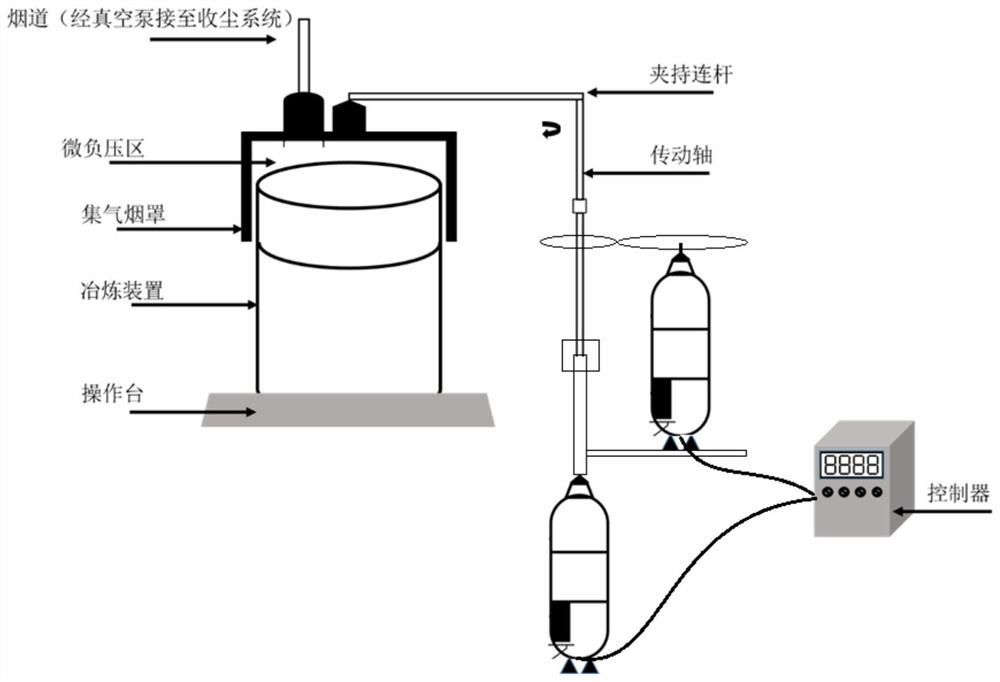

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1: a kind of method for micro-negative pressure refining of industrial silicon melt outside the furnace, the specific steps are as follows:

[0030] (1) In the production of an industrial silicon smelting enterprise in Yunnan, about 2 tons of silicon melt released from the submerged arc submerged arc electric furnace are packed in the refining ladle outside the furnace. In order to further reduce Al and Ca, the silicon melt in the ladle is The silicon melt is oxidized and gas blown again; in terms of mass percentage, the impurity content in the silicon melt is 8000ppm for Al and 15000ppm for Ca;

[0031] (2) The silicon melt of step (1) is carried out oxidation blowing refining, wherein the blowing mode of oxidation blowing refining is top blowing ventilation, and gas is industrial oxygen, and top blowing ventilation time is 0.5h, and top blowing ventilation pressure is 1.2 to 2 atmospheres, gas velocity 0.2 to 1m 3 / s;

[0032](3) While step (2) is oxidizi...

Embodiment 2

[0035] Embodiment 2: a kind of method for micro-negative pressure refining of industrial silicon melt outside the furnace, the specific steps are as follows:

[0036] (1) In the production of an industrial silicon smelting enterprise in Yunnan, about 2 tons of silicon melt released from the submerged arc ore electric furnace were put into the refining ladle outside the furnace. In order to further reduce Al and Ca, the silicon melt in the ladle was The silicon melt is subjected to slagging and refining; in terms of mass percentage, the impurity content in the silicon melt is 6000ppm for Al and 1300ppm for Ca;

[0037] (2) Add slag-forming agent CaO in step (1) silicon melt, then feed industrial compressed nitrogen to carry out slagging refining, in terms of silicon melt, wherein the add-on of slag-forming agent CaO is 2kg / ton, industrial The ventilation time with compressed nitrogen is 15 minutes;

[0038] (3) At the same time of step (2) slagging and refining, micro-negative...

Embodiment 3

[0041] Embodiment 3: a kind of method for micro-negative pressure refining of industrial silicon melt outside the furnace, the specific steps are as follows:

[0042] (1) In the production of an industrial silicon smelting enterprise in Yunnan, about 2 tons of silicon melt released from the submerged arc ore electric furnace were put into the refining ladle outside the furnace. In order to further reduce Al and Ca, the silicon melt in the ladle was The silicon melt is subjected to blowing-slagging compound refining; in terms of mass percentage, the impurity content in the silicon melt is 5000ppm for Al and 1100ppm for Ca;

[0043] (2) Add slag-forming agent CaO to the silicon melt in step (1), and then feed industrial oxygen to carry out air blowing-slagging compound refining, in terms of silicon melt, wherein the amount of slag-forming agent CaO added is 1kg / ton , when gas blowing-slagging compound refining, the way of introducing industrial oxygen is top blowing ventilation,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com