Celadon coded lock and firing process thereof

A combination lock and celadon technology, applied in the field of celadon combination lock and its firing process, to achieve high aesthetics, less internal holes, and improved mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

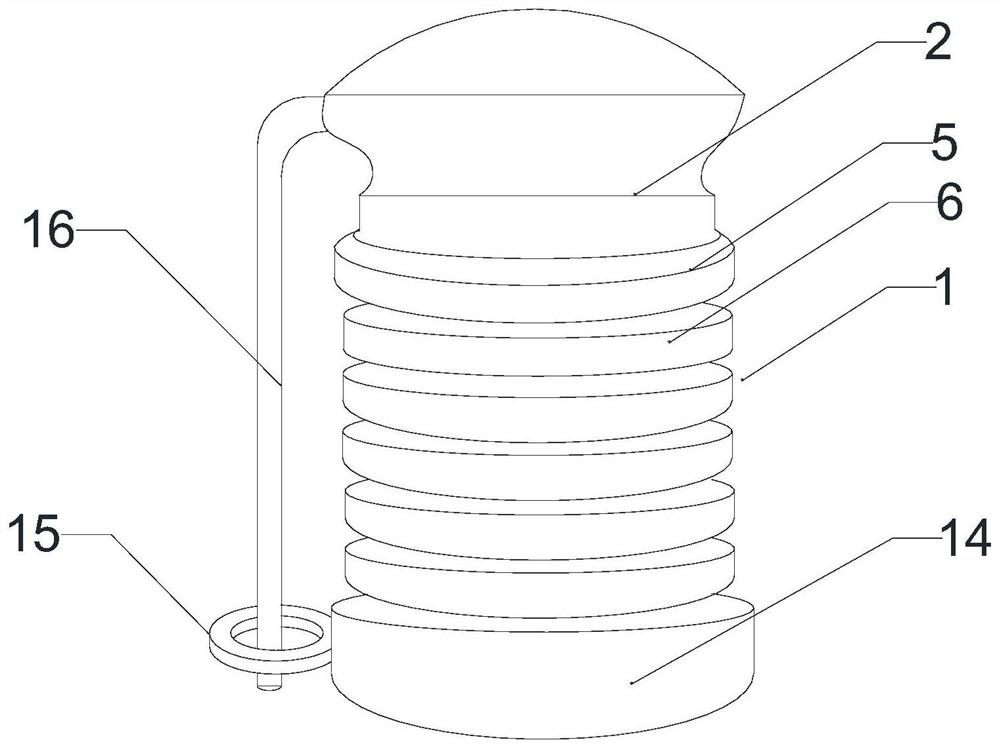

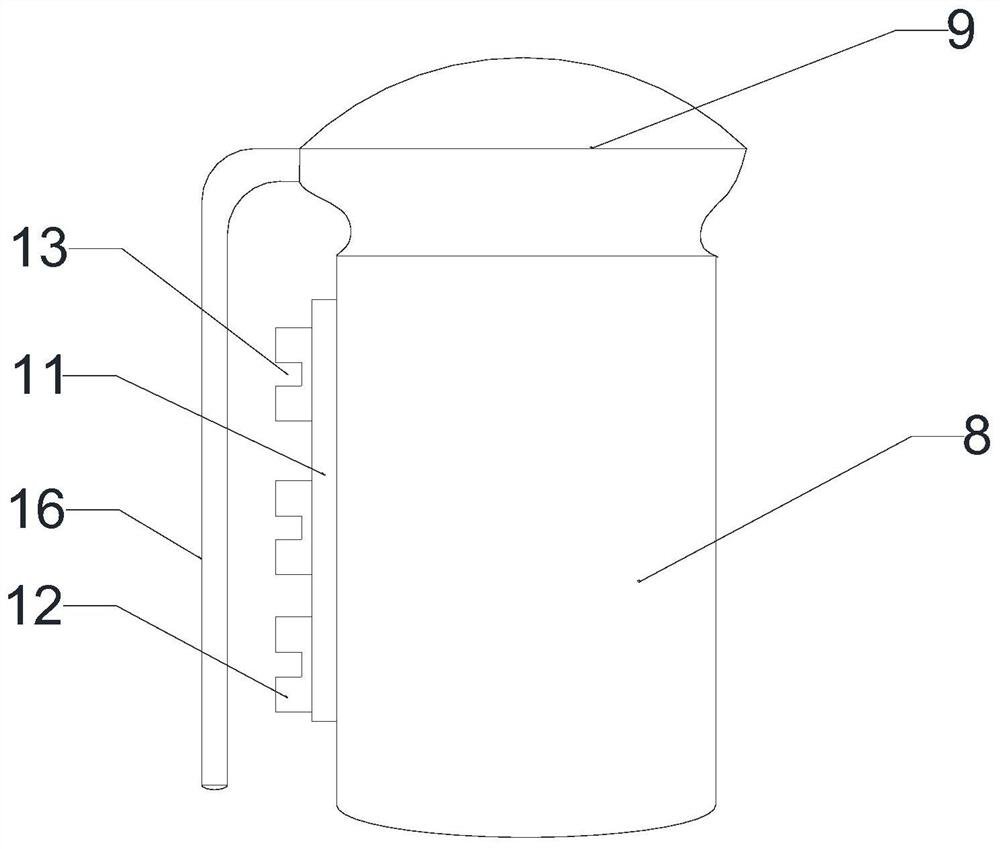

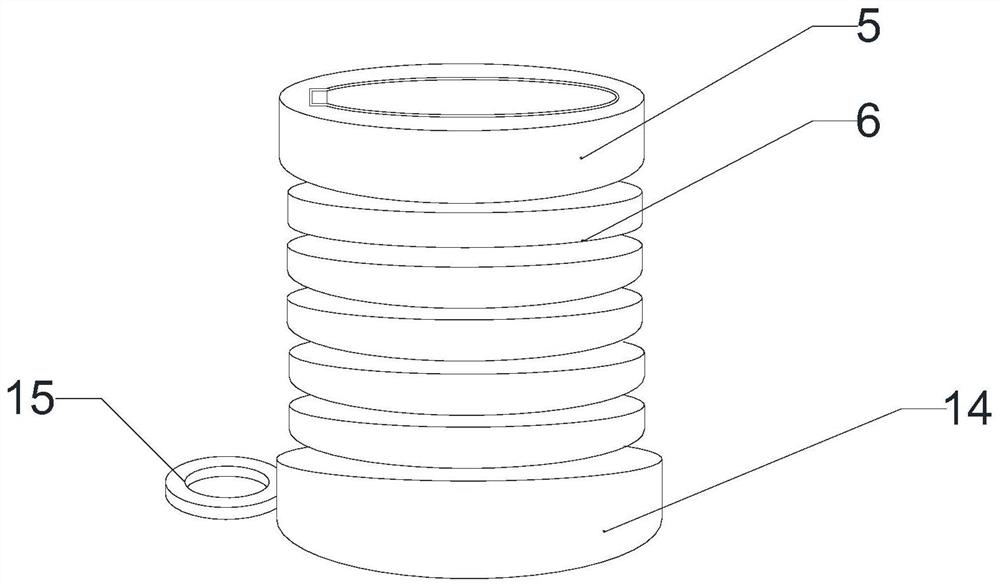

[0047] Such as Figure 1~7 Shown, a kind of celadon combination lock, described celadon combination lock comprises a lock body 1 made of celadon and a lock core 2 made of celadon, the inside of the lock body 1 is a hollow cylindrical The lock cylinder 3, the lock cylinder 3 is provided with a slot 4 in the vertical direction, and several fixed rings 5 and rotating rings 6 are arranged alternately outside the lock cylinder 3, and the fixed rings 5 and the rotating rings The inner diameter of 6 is the same as the outer diameter of the lock cylinder 3, a notch 7 is provided on the inner surface of the fixed ring 5 and the rotating ring 6, and the surface of the rotating ring is provided with numbers or letter marks uniformly arranged on the surface, and the fixed The gap 7 on the ring 5 is in the same position as the slot 4. The lock core 2 includes a cylindrical stem 8 and a cover 9 arranged on the upper end of the stem 8. The stem 8 is hollow. Its inside is provided with a...

Embodiment 2

[0050] Such as Figure 8 As shown, it is a modified embodiment of the present invention, and its difference from Embodiment 1 is that the lock body 1 and the lock cylinder 2 are arranged in an arc shape, and the base 14 is rotatably connected with the cover body 9 , when the lock body 1 and the lock cylinder (2) are rotated and inserted into each other, and then the rotating ring 6 is rotated, the two can be spliced together to form a handcuff-shaped circular celadon combination lock.

[0051] Firing process of celadon combination lock

Embodiment 3

[0053] A firing process of the aforementioned celadon combination lock, the firing process comprises the following steps:

[0054] (1) Billet preparation: Grind kaolin and sieve it with water, sodium carboxymethyl cellulose, polyphenylsilsesquioxane, albite powder, titanium dioxide and zirconium dioxide according to the ratio of 100:20:0.5:0.3:2 : 0.5: 0.2 mixed, and the billet was obtained after stirring evenly;

[0055] (2) Manufacture of lock body and lock core blank: shape the blank according to the specified shape to make the lock body blank and lock core blank;

[0056] (3) Biscuit firing: After drying the manufactured lock body blank and lock cylinder blank body, biscuit firing at 850°C for 3 hours to obtain the lock body and lock cylinder semi-finished products;

[0057] (4) Glazing: Evenly coat a layer of glaze on the surface of the lock body and the semi-finished lock cylinder, wherein the gap between the lock body's fixed ring and the lock cylinder is filled with g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com