Self-suspending proppant based on aerodynamic effect, and preparation method thereof

A proppant, self-suspension technology, applied in chemical instruments and methods, earthwork drilling, drilling composition, etc., can solve the problem of fast settling speed, the effective support length of hydraulic fractures does not meet the design requirements, proppant migration Short distance and other problems, to achieve the effect of easy access, reduce the amount of pre-liquid, and facilitate transportation and storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

[0049] The experimental plan is as follows:

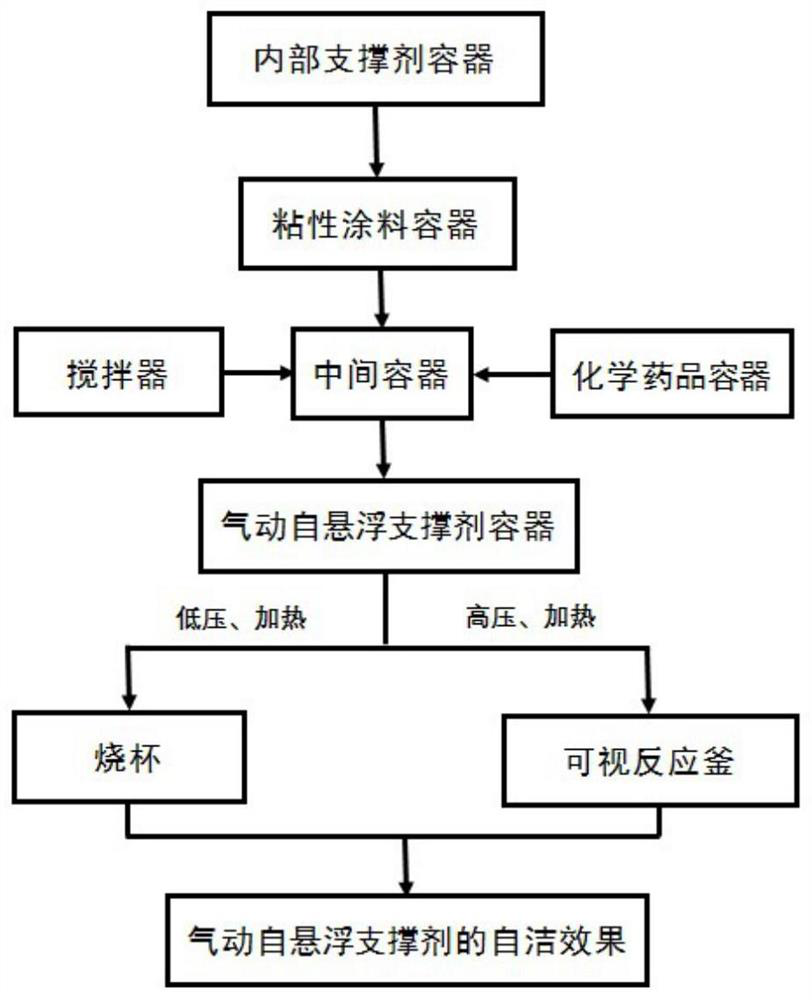

[0050] (1) Arrange the indoor experimental site according to figure 1 Each experimental device is installed as shown;

[0051] (2) Example 1-6 proppant selection diameter is 2mm, apparent density is 1.26g / cm 3 10g of rubber particles, 3.5g of silica gel glue with a viscosity of 38000mpa s for the middle viscous coating, and ammonium chloride and sodium nitrite for the outer coating material. : 1.3 ratio mixing;

[0052] (3) Pour the internal proppant from its container into a viscous paint container filled with silicone glue, and stir evenly so that the internal proppant is evenly attached to the silicone glue, and the internal proppant is evenly attached to the adhesive silica gel, and then transferred to the intermediate container , Pour chemicals from their containers into the intermediate container, and under the action of the stirrer, the surface of the internal proppant with adhesive silica gel is evenly wrapped with chemi...

Embodiment 7-12

[0062] A self-suspending proppant based on aerodynamic effect and its preparation method as described in Examples 1-6, the difference is that the rubber particles are changed to 20-40 mesh and the density is 1.8g / cm 3 The medium density ceramsite 10g, other experimental conditions are the same, the experimental results obtained through the experiment are shown in Table 2.

[0063] Table 2 The relationship between the amount of proppant coating drug and the suspension time of proppant under low pressure conditions

[0064]

[0065] The experimental results and experimental phenomena of Examples 7-12 are similar to those of Examples 1-6. When the internal proppant is medium-density ceramsite, the modified proppant can still achieve self-suspension, which shows that this modified proppant is applicable Used in laboratories and mines.

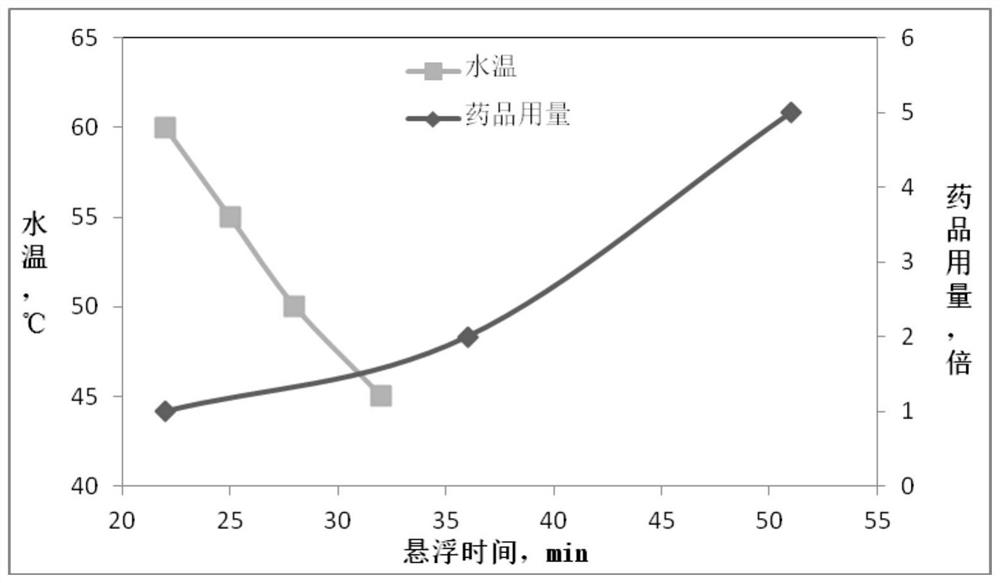

[0066] Draw according to the experimental data in embodiment 7-12 and obtain as image 3 Under normal pressure conditions shown, the relation...

Embodiment 13-15

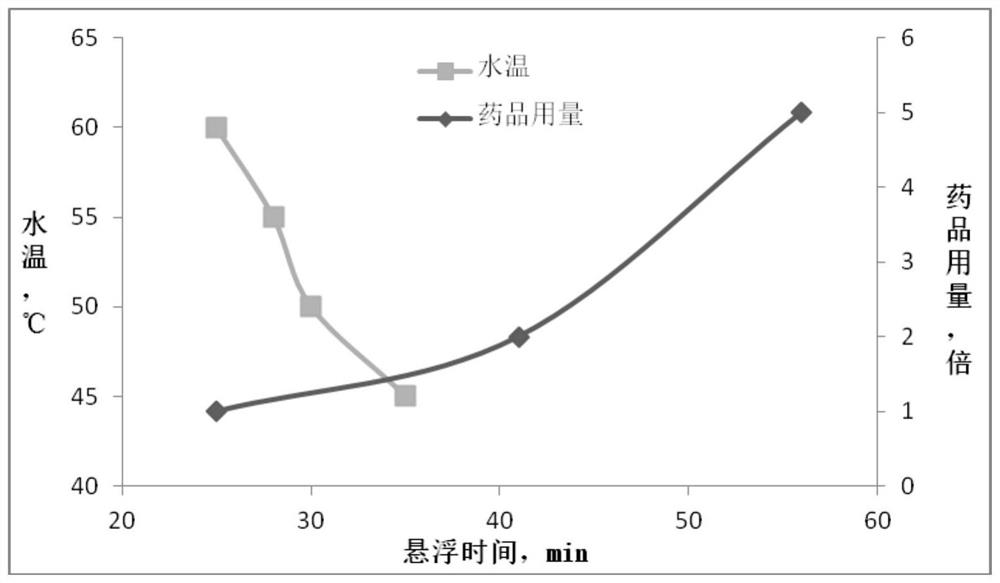

[0069] A self-suspending proppant based on aerodynamic effect and its preparation method as described in Examples 1-12, the difference is that in Examples 13-15, it is the difference between the dosage of the proppant outer coating drug and the suspension time of the proppant under high pressure conditions. The initial temperature of the water is kept constant at 40°C, the amount of the proppant coating drug and the pressure in the visual reactor are changed, and the other experimental conditions are the same. The suspension time of the pneumatic self-suspension proppant is obtained through the experiment as shown in Table 3 Shown:

[0070] Table 3 The relationship between the dosage of proppant outer coating drug and the suspension time of proppant under high pressure condition

[0071]

[0072]

[0073] It can be seen from the experimental results that this kind of modified proppant can not only achieve self-suspension under low pressure conditions, but also can achiev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com