A low-nox burner for resource utilization of extremely low calorific value associated gas and carbon black burnout

An associated gas and burner technology, which is applied in the direction of combustion type, combustion method, incinerator, etc., can solve the problems of particulate matter emission, environmental pollution, threat to human health, etc., to reduce the generation of fuel-related NOx, improve gas utilization efficiency, and improve The effect of stabilizing ignition and economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

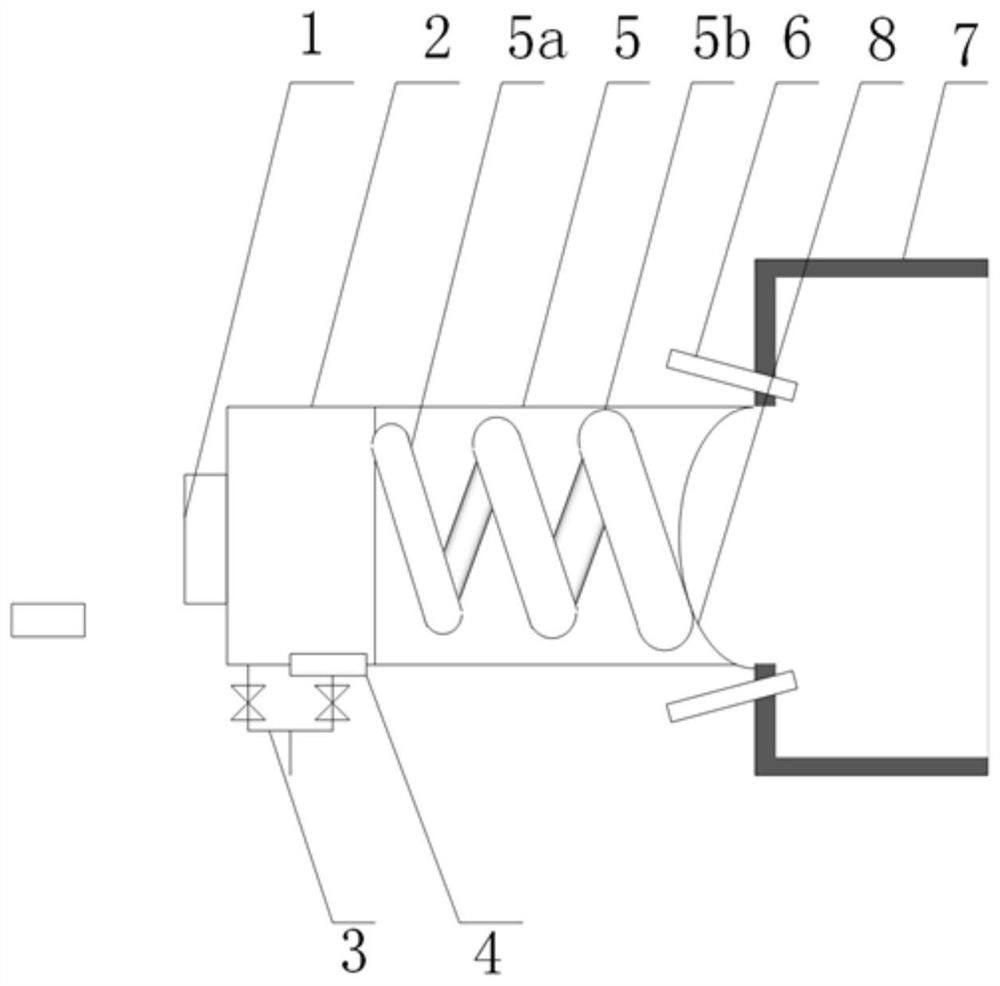

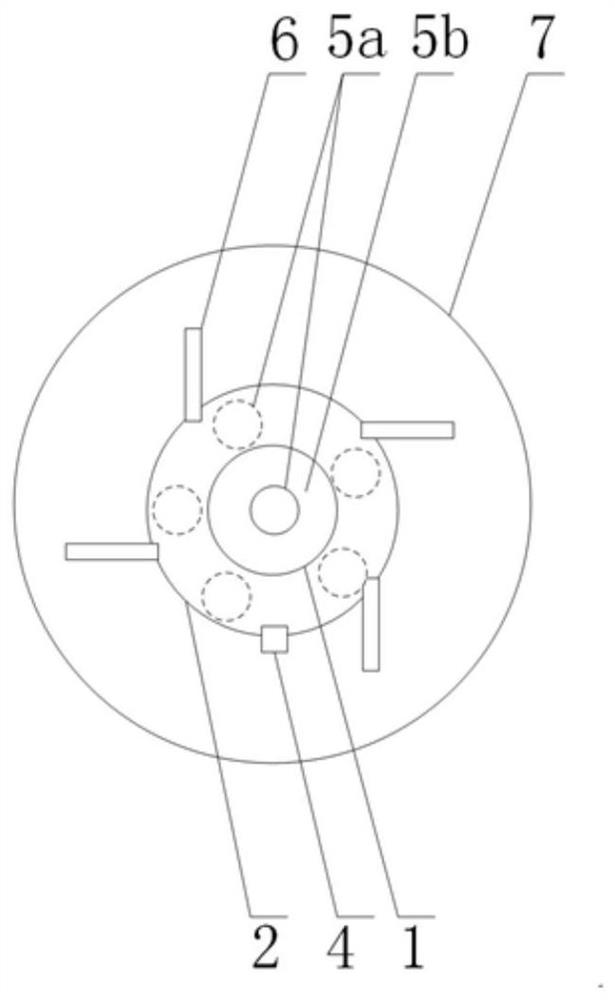

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0023] see figure 1 figure 2 , The technical solution adopted in the present invention is: a new type of low-calorific-value associated gas and carbon black burnout (activated carbon carbonization furnace pyrolysis gas and activation furnace associated gas) low NOx burner. Low calorific value gas inlet 1, ignition chamber 2, primary air inlet 3, combustion-supporting device 4, swirl channel regenerative burner 5, swirl burn-off air 6, burn-out chamber or furnace 7, recessed heat-accumulating burner 8. The extremely low calorific value gas produced in the activated carbon manufacturing process enters from the low calorific value gas inlet 1, and the primary air entering the primary air inlet 3 and the pyrolysis gas generated by the raw coal in the combustion supporting device 4 enter the cyclone after being ignited in the ignition chamber 2. The heat storag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com