Gas stove working method and gas stove

A working method and technology of gas stoves, applied in heating fuel, household stove/stove, gaseous heating fuel, etc., can solve the problem of not being able to directly obtain the combustion efficiency of gas stoves, and achieve the effect of saving gas and improving combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

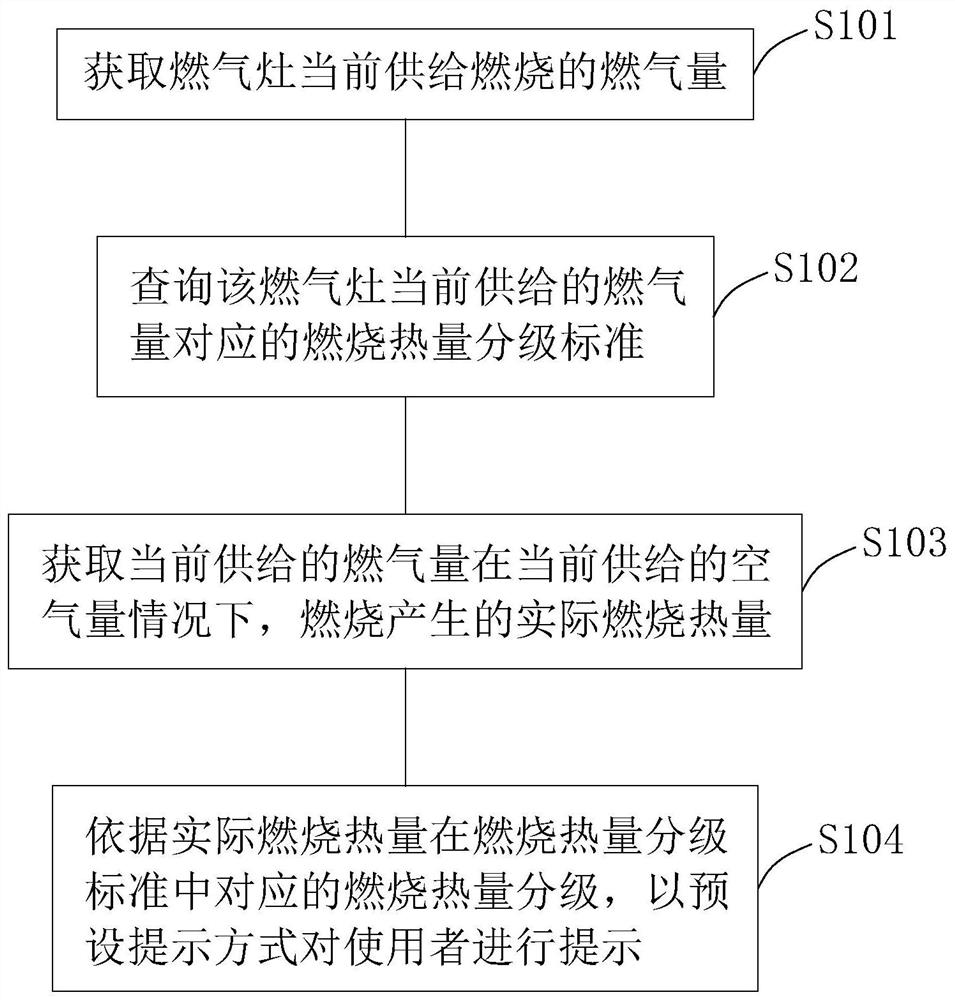

[0053] A kind of working method of gas cooker, refer to figure 1 , including step S101 to step S104.

[0054] Step S101: Obtain the amount of gas currently supplied by the gas stove for combustion.

[0055] In this embodiment, the amount of gas supplied is detected by monitoring the degree of opening of the gas valve to supply gas. Specifically, a synchronously rotating potentiometer can be set on the knob of the gas valve. When the gas valve is rotated and adjusted, the potentiometer converts the degree of opening to for the corresponding electrical signal.

[0056] Step S102: Query the combustion heat classification standard corresponding to the gas quantity currently supplied by the gas stove.

[0057]Based on the obtained gas volume value, query the corresponding combustion heat classification standard. The combustion heat classification standard is the amount of heat generated by the gas stove after full combustion under the condition of supplying the gas amount. This s...

Embodiment 2

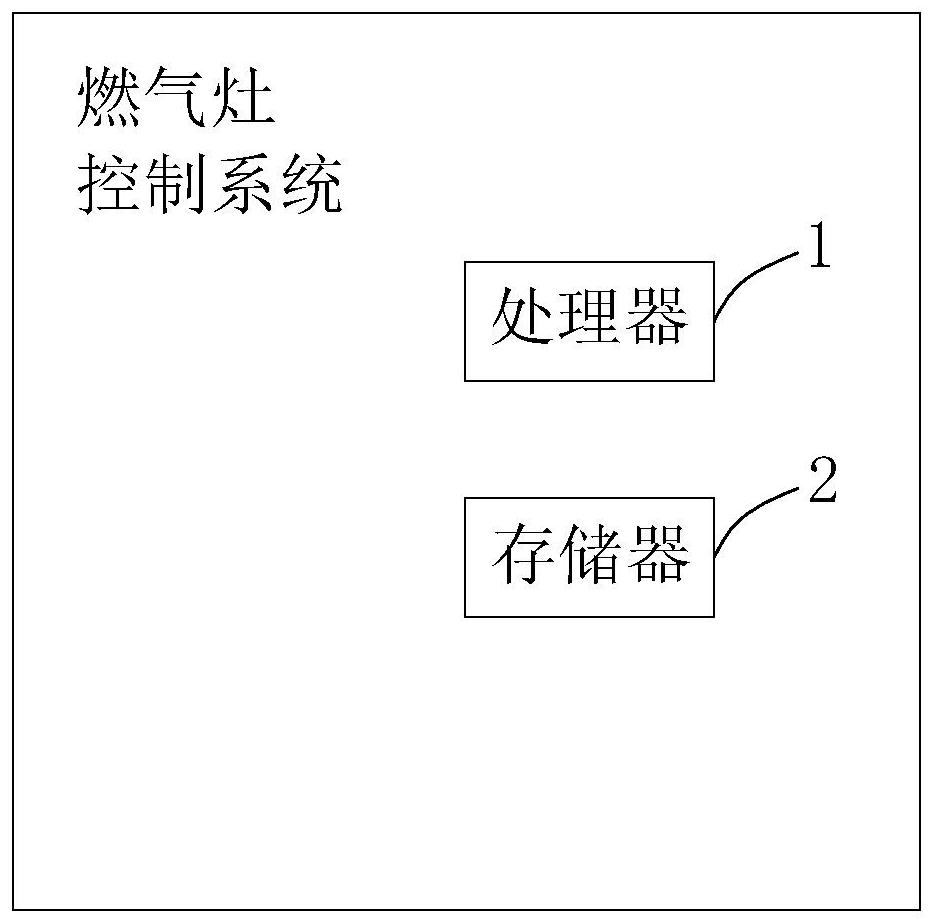

[0075] A gas cooker, including a gas cooker control system, referring to figure 2 , the gas stove control system includes a processor 1 and a memory 2, and the memory 2 stores an instruction set for the processor 1 to call to realize the following functions: when the gas stove is working,

[0076] Obtain the amount of gas currently supplied by the gas stove for combustion;

[0077] Query the combustion heat classification standard corresponding to the gas quantity currently supplied by the gas stove;

[0078] Obtain the actual combustion heat generated by the combustion of the current supplied gas volume and the current supplied air volume;

[0079] According to the actual combustion calorie in the combustion calorie classification standard corresponding to the combustion calorie classification, the user is reminded in a preset prompt manner.

[0080] Further, when notifying the user in a preset prompting manner, it includes displaying the current burning calorie rating, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com