Pressure sensor with double-air-inlet-pipe structure

A pressure sensor and air intake pipe technology, applied in the sensor field, can solve the problems of unreasonable use of resources, increase the workload of installers and inspection personnel, increase the use of pressure sensors, etc., and achieve the effect of improving the conduction effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

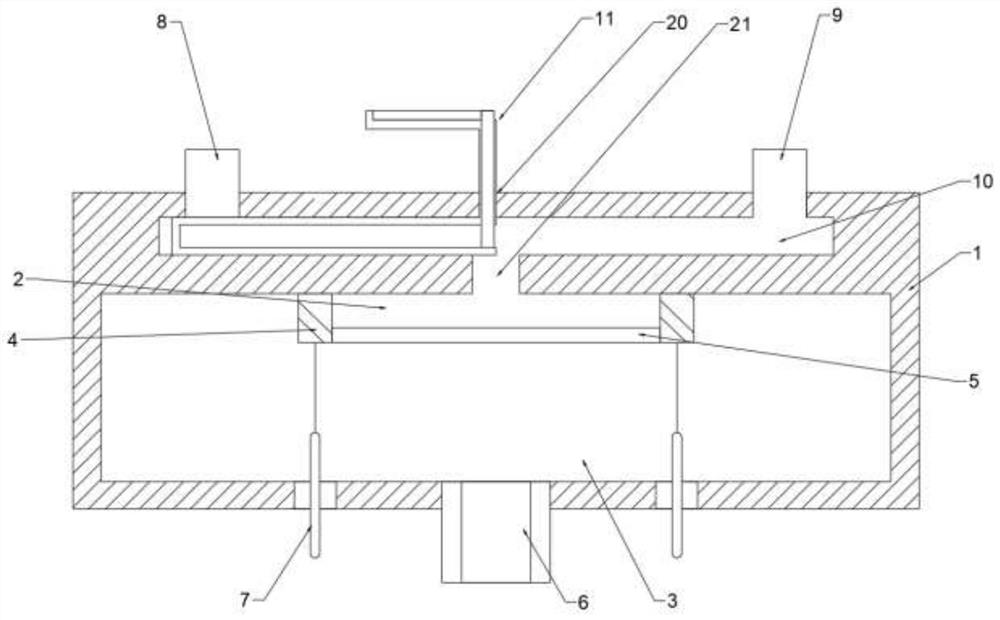

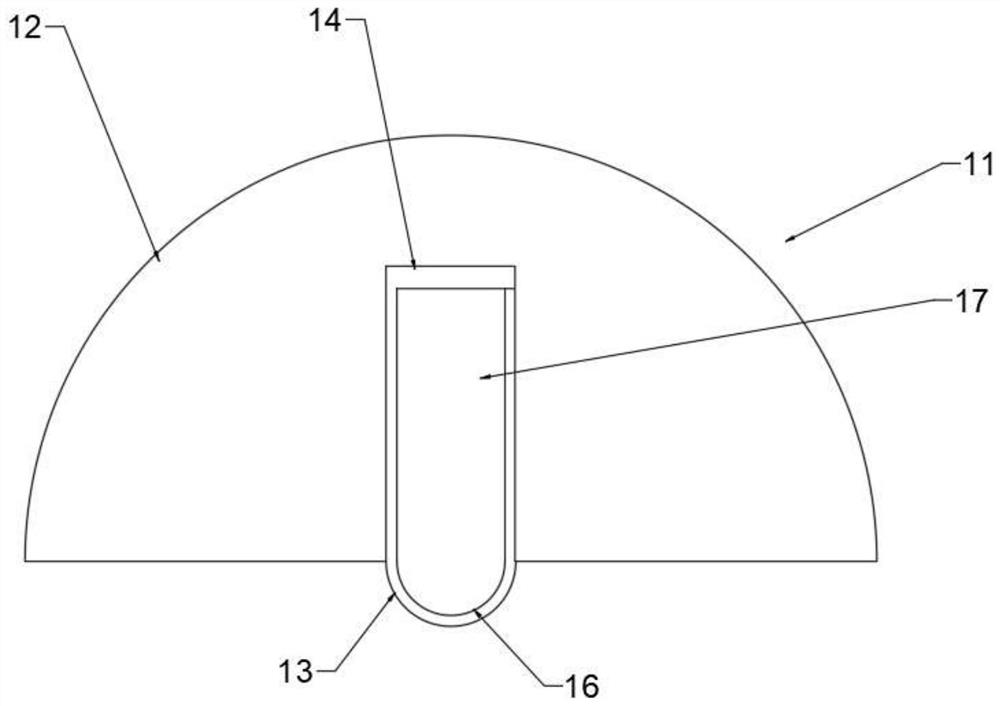

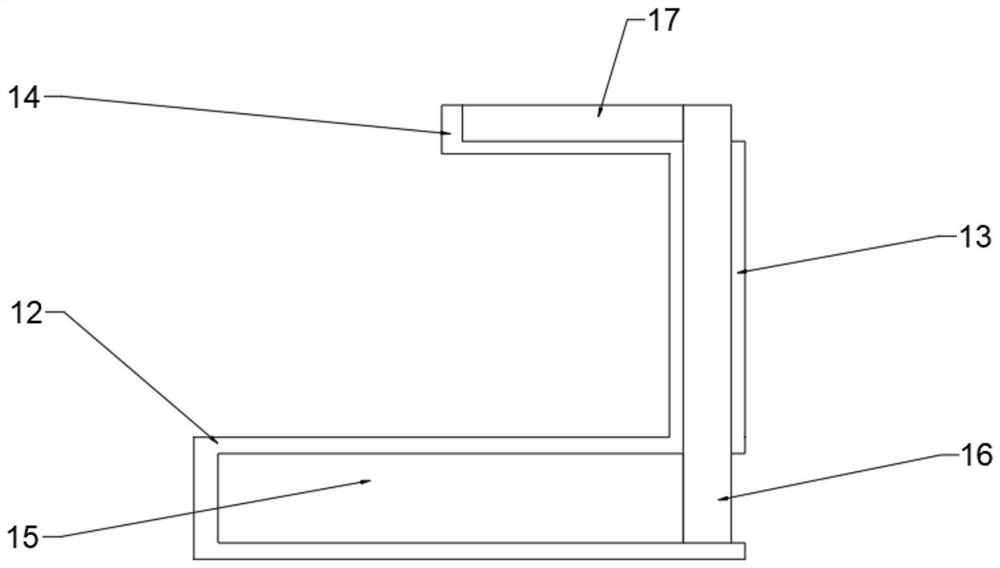

[0027] see Figure 1 to Figure 4 , a pressure sensor with a dual air intake pipe structure, comprising a housing 1, a cylindrical groove 10 is provided inside the housing 1, a silicon ring 4 is provided at the bottom of the cylindrical groove 10, and a silicon diaphragm 5 is provided at the bottom of the silicon ring 4 , the inside of the housing 1 is divided into a high-pressure chamber 2 and a low-pressure chamber 3 by a silicon diaphragm 5, a left inlet 8 is provided on the left side of the top of the housing 1, a right inlet 9 is provided on the right side of the top of the housing 1, and the left Both the inlet 8 and the right inlet 9 are in communication with the cylindrical groove 10, the cylindrical groove 10 is provided with a regulator 11, and the left inlet 8 and the right inlet 9 are used to connect the passages that need to detect the pressure in the outside world, and the pressure of the silicon diaphragm 5 is controlled by the air pressure. function to detect th...

Embodiment 2

[0035] see Figure 1 to Figure 5, such as a pressure sensor with a double inlet pipe structure in Embodiment 1, including a housing 1, a cylindrical groove 10 is provided inside the housing 1, a silicon ring 4 is provided at the bottom of the cylindrical groove 10, and a silicon ring 4 is provided at the bottom of the silicon ring 4. A silicon diaphragm 5 is provided, and the interior of the housing 1 is divided into a high-pressure chamber 2 and a low-pressure chamber 3 through the silicon diaphragm 5. A left inlet 8 is provided on the left side of the top of the housing 1, and a right inlet 8 is provided on the right side of the top of the housing 1. The inlet 9, the left inlet 8 and the right inlet 9 are all in communication with the cylindrical tank 10, the cylindrical tank 10 is provided with a regulator 11, and the left inlet 8 and the right inlet 9 are used to connect the passages that need to detect pressure from the outside world, and the air pressure The effect of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com