Analysis method of embedded electroplating leveling agent into IC support plate through hole

An analysis method and leveling agent technology, which is applied in the field of analysis of through-hole filling electroplating leveling agents on IC substrates, can solve the problems of difficult cleaning of analysis electrodes, shortened service life of electrodes, unstable analysis results, etc., and achieve simple verification Clear, prolong service life, beneficial to the effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Instruments and Conditions:

[0041] CVS instrument: Metrohm automatic 894CVS analyzer;

[0042] Working electrode: platinum electrode;

[0043] Electrode speed: 2600 rpm;

[0044] electrolyte;

[0045] Working temperature: 23°C

[0046] Analytical positive voltage: 1.625V;

[0047] Analyzing negative voltage: 0.175V;

[0048] Analysis steps:

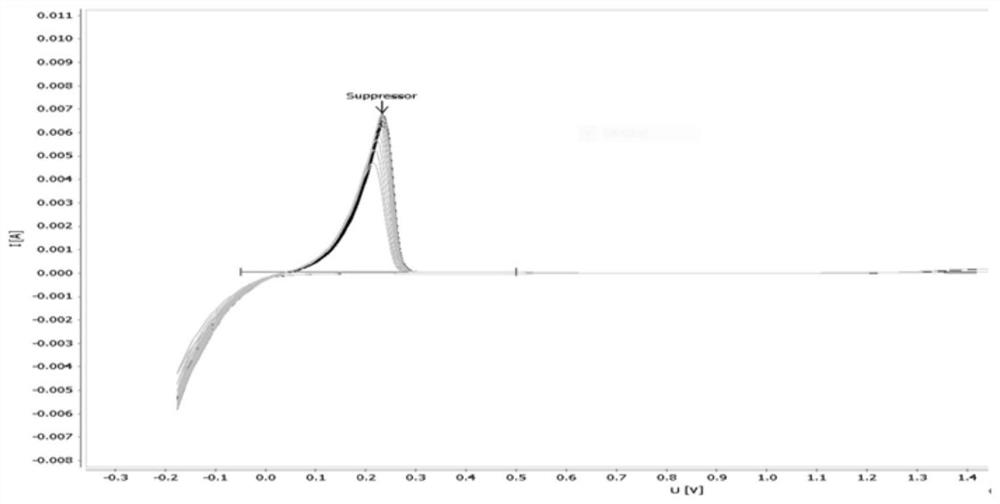

[0049] The first electrode activation: Before the instrument analysis, place a blank VMS solution under the electrode and perform 15 electrode activations to ensure that the potential difference of the electrodes after two consecutive activations is less than 0.2%.

[0050] Make a standard curve: place 20ml of electrolyte solution under the electrode of the analyzer, place 5ml of standard solution into the autosampler of the analyzer, start the analyzer, and obtain the standard curve and correction factor.

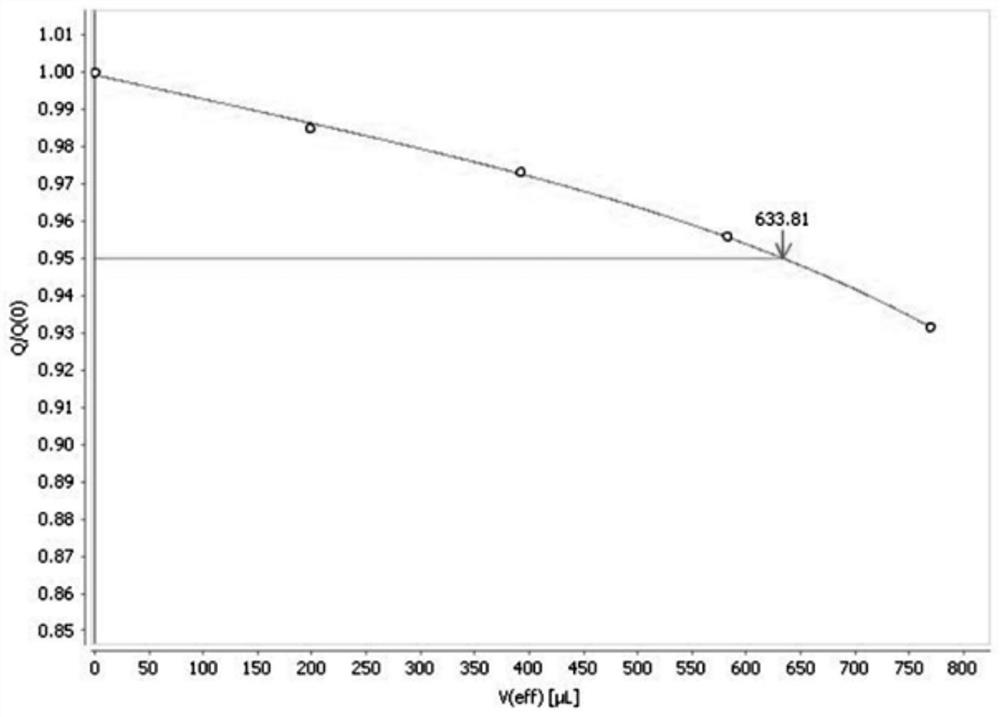

[0051] Verify the correction factor: place the 20ml electrolyte under the electrode of the analyzer, place 5ml of th...

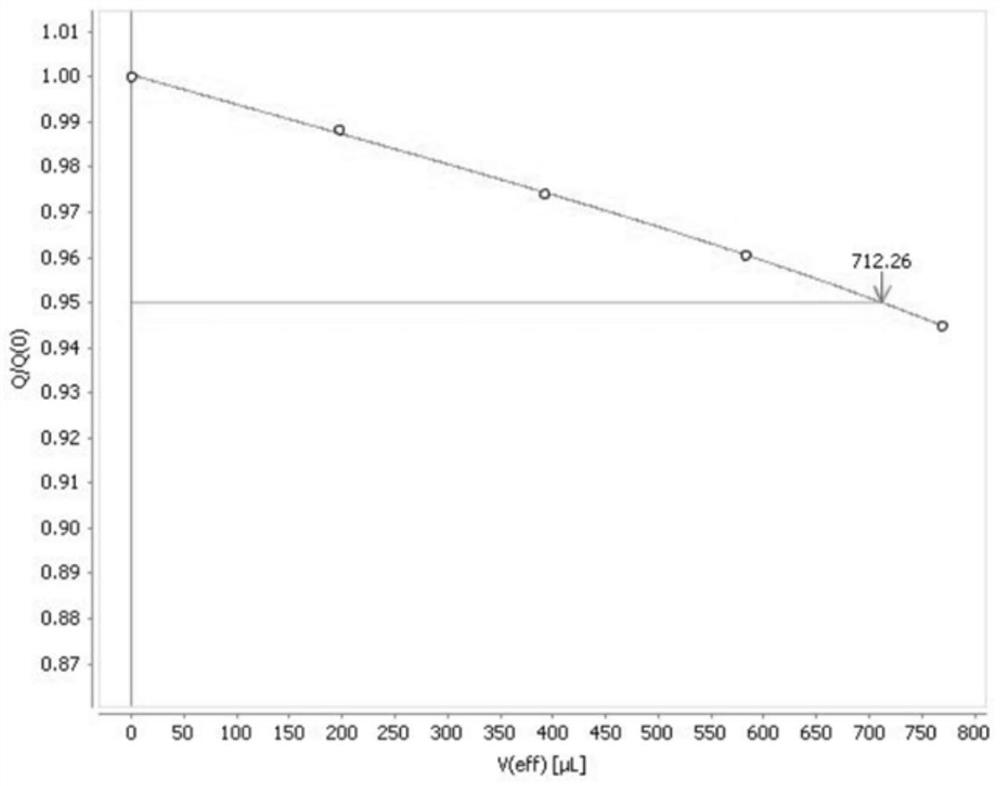

Embodiment 2

[0058] Instruments and Conditions:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com